Scouring agent feeding apparatus of rotating drum washing machine

A technology of a drum type washing machine and a supply device, which is applied to washing devices, other washing machines, applications, etc., and can solve problems such as shaking of the detergent cylinder cover 48, and achieve the effect of preventing accidental detachment and preventing complete detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

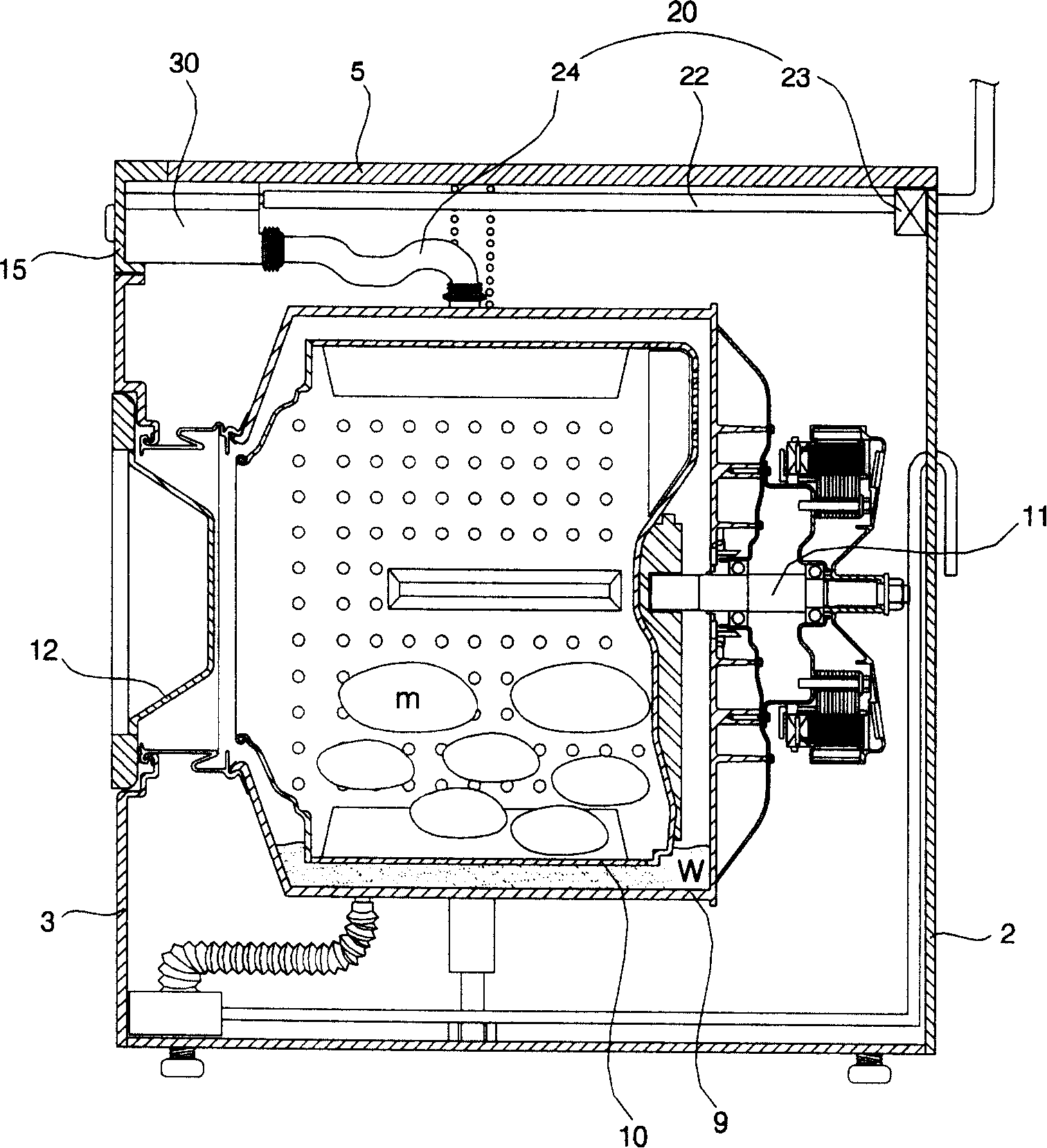

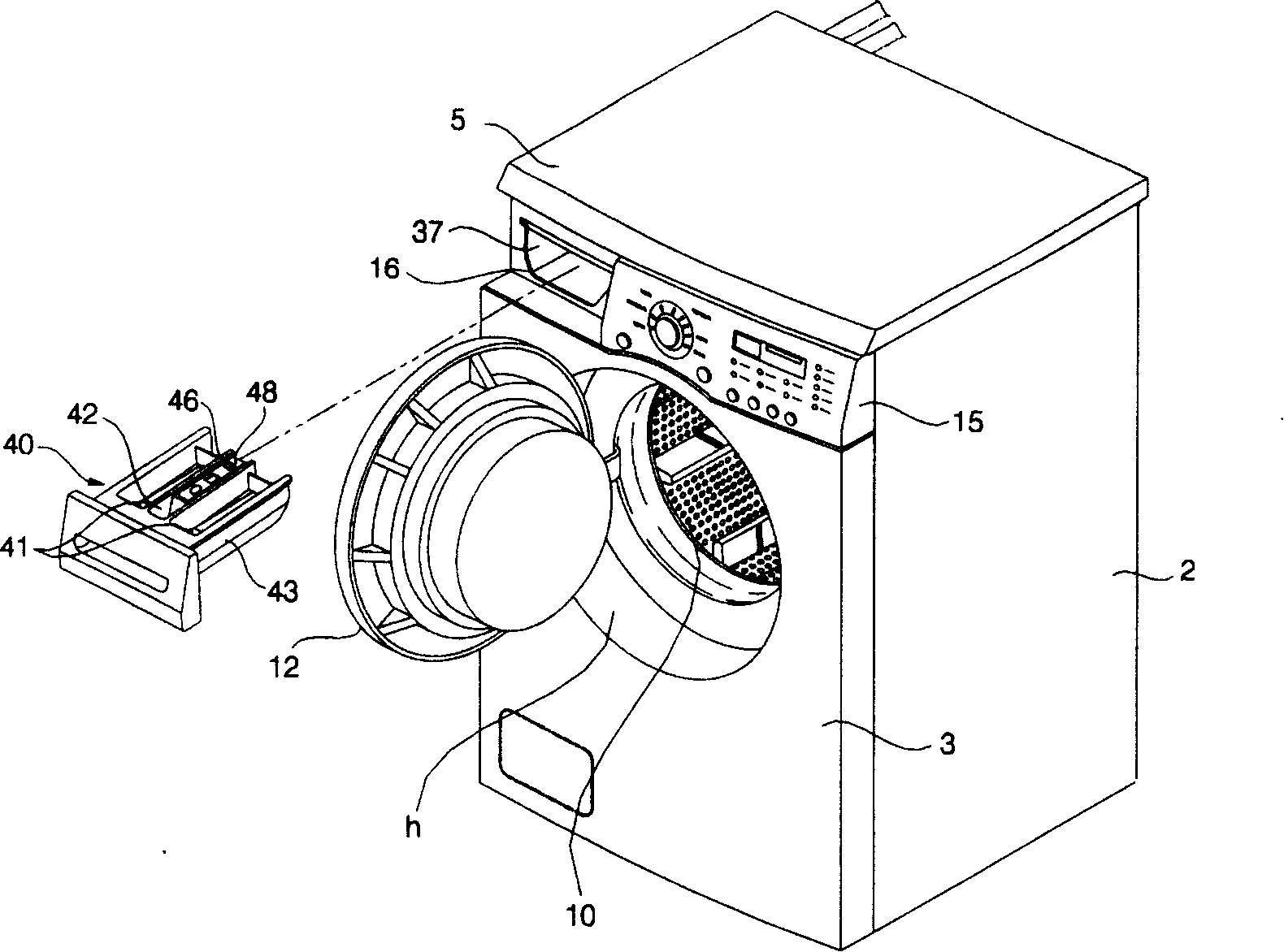

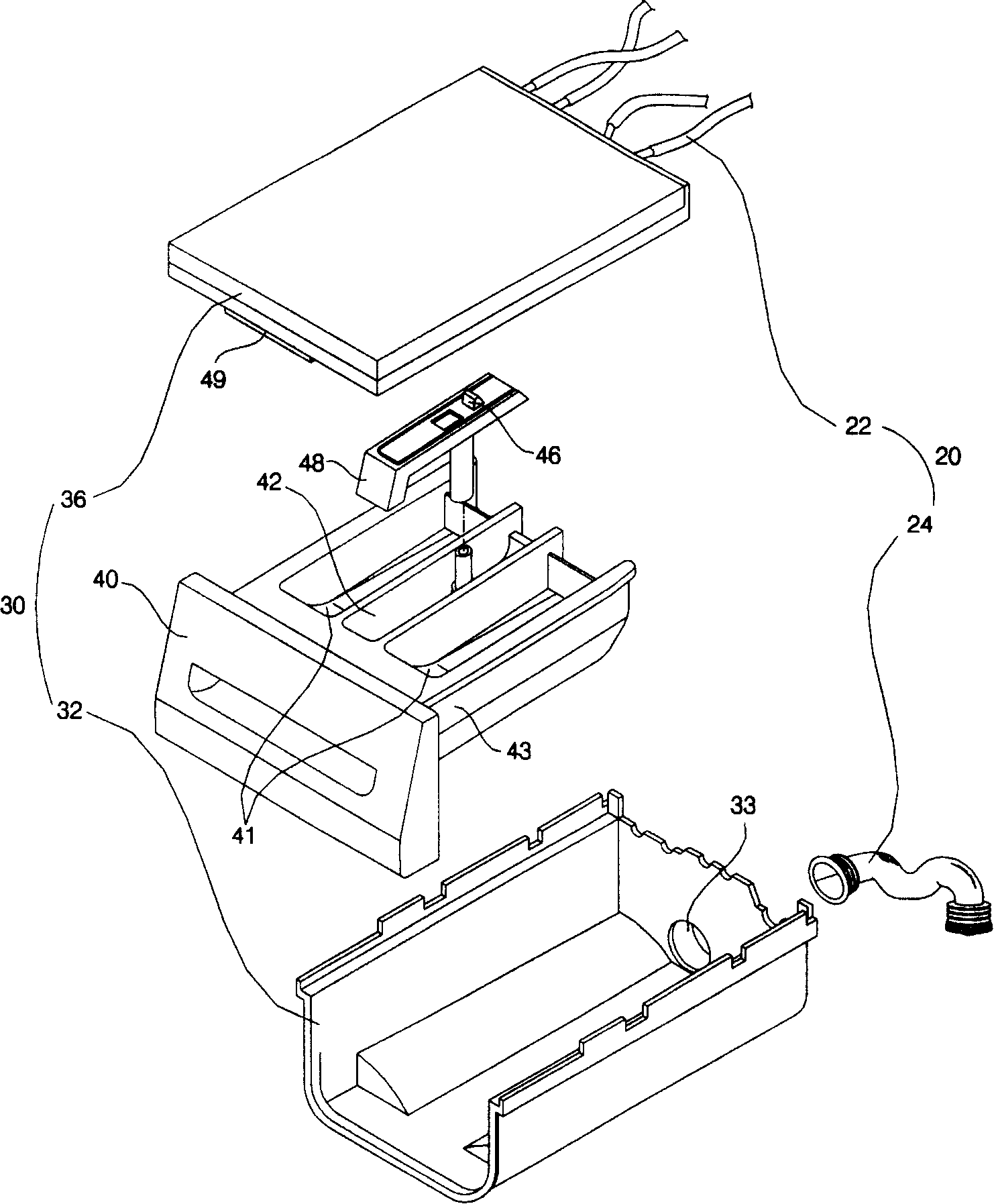

[0055] Figure 4 It is a schematic diagram of an exploded structure of Embodiment 1 of the detergent supply device for a drum-type washing machine of the present invention. Figure 5 It is a schematic structural view of the detergent cylinder in Embodiment 1 of the detergent supply device for a drum-type washing machine of the present invention. Figure 6 It is a schematic diagram of the locked state of the detergent cylinder in Embodiment 1 of the detergent supply device of the drum type washing machine of the present invention. Figure 7 It is a schematic diagram of the unlocked state of the detergent cylinder in Embodiment 1 of the detergent supply device for a drum-type washing machine of the present invention.

[0056] Such as Figure 4 , 5 , 6 and 7, the detergent supply device 80 of the drum-type washing machine of the present invention includes: a detergent cylinder setting part communicated with the inside of the detergent cylinder inlet and outlet (not shown) form...

Embodiment 2

[0076] Figure 8 It is a structural schematic diagram of the detergent cylinder in Embodiment 2 of the detergent supply device for a drum-type washing machine of the present invention.

[0077] Such as Figure 7 As shown, the drum washing machine detergent drum 90 of this embodiment includes: a front portion 94 forming the front face of the detergent drum 90; Accommodating portion 96; The said detergent accommodating portion 96 is divided into the isolation portion 98 of the main detergent accommodating portion 96a and the preparatory detergent accommodating portion 96b; it is detachably arranged on the above described preparatory detergent accommodating portion 96b. Auxiliary detergent container 97 for accommodating bleach or softener.

[0078] The detergent cylinder 90 is formed with two accommodating parts 96 for containing powdered detergent. When washing stubborn stains or initial washing, the washing water dissolved with detergent can flow into the outer tub twice (not...

Embodiment 3

[0080] Figure 9 It is a structural schematic diagram of the detergent cylinder in Embodiment 3 of the detergent supply device for a drum-type washing machine of the present invention.

[0081] Such as Figure 8 As shown, the detergent drum 90 of the drum type washing machine in this embodiment is integrally formed on the top surface of the isolation portion 98 with a hooking step 100 to prevent it from completely detaching when the detergent drum 90 is pulled out, and the description is omitted. The elastic part 110 in the first embodiment.

[0082] Generally, for public commercial washing machines, the detergent cylinder 90 is made so that it cannot be completely separated from the drum type washing machine, so as to prevent the detergent cylinder 90 from being lost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com