Drive type reversion polisher

A polishing machine and active technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, optical surface grinders, etc., can solve the problems of low efficiency of large-diameter workpieces, large vibration of polishing equipment, and increased centrifugal inertial force. Achieve the effect of simple structure, stable grinding and smooth grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

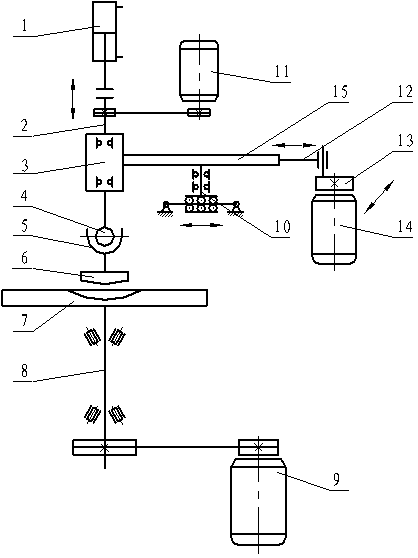

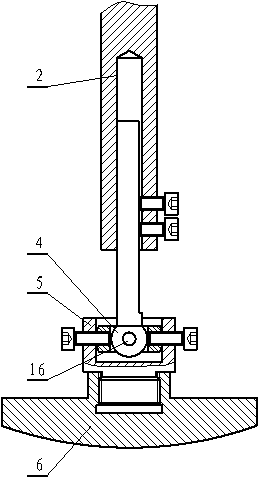

[0016] Such as figure 1 , figure 2 Shown: an active reverse polishing machine, including an upper plate part and a lower plate part with opposite rotation directions, the upper plate part includes a polishing mold 6, an upper shaft 2 and a swing mechanism connected in sequence, and the polishing mold 6 and the The upper shaft 2 is connected through a spherical mechanism, and the upper shaft is also connected with a pressurizing mechanism and a rotating mechanism. The lower plate part includes a workpiece pallet 7, a workpiece spindle 8 and a workpiece motor 9 connected in sequence, and the workpiece motor 9 can be adjusted by frequency conversion.

[0017] As a preferred solution of the present invention, the spherical mechanism includes a rotating ball head 4 arranged at the lower end of the upper shaft 2 and a rotating spherical seat 5 arranged on the polishing mold 6, and the polishing mold 6 is connected to the rotating spherical The seats 5 are threadedly connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com