Method and whole set of impurity removing equipment for removing impurities in lake and river silt

A silt and complete set of technology, applied in the field of silt utilization, can solve the problems of destroying the force-bearing structure of the brick body, affecting the compressive strength of the brick body, and difficult to guarantee the flatness of the wall body, so as to improve the quality and slurry yield, and reduce the waste of land. The effect of occupation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

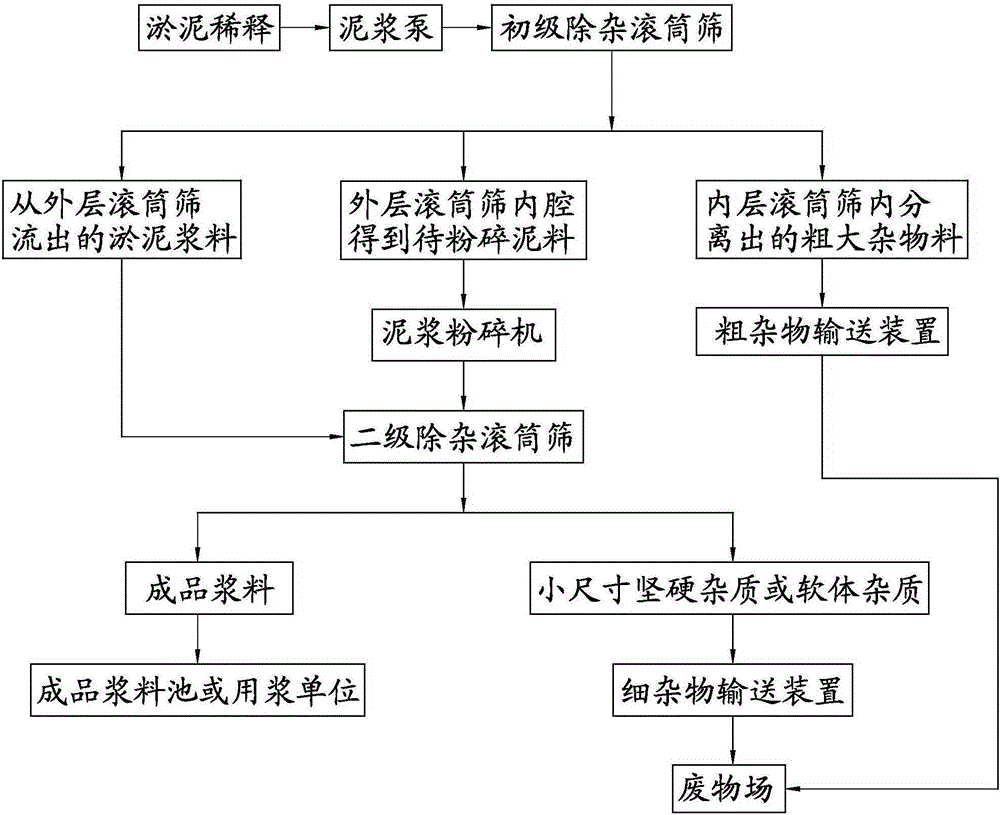

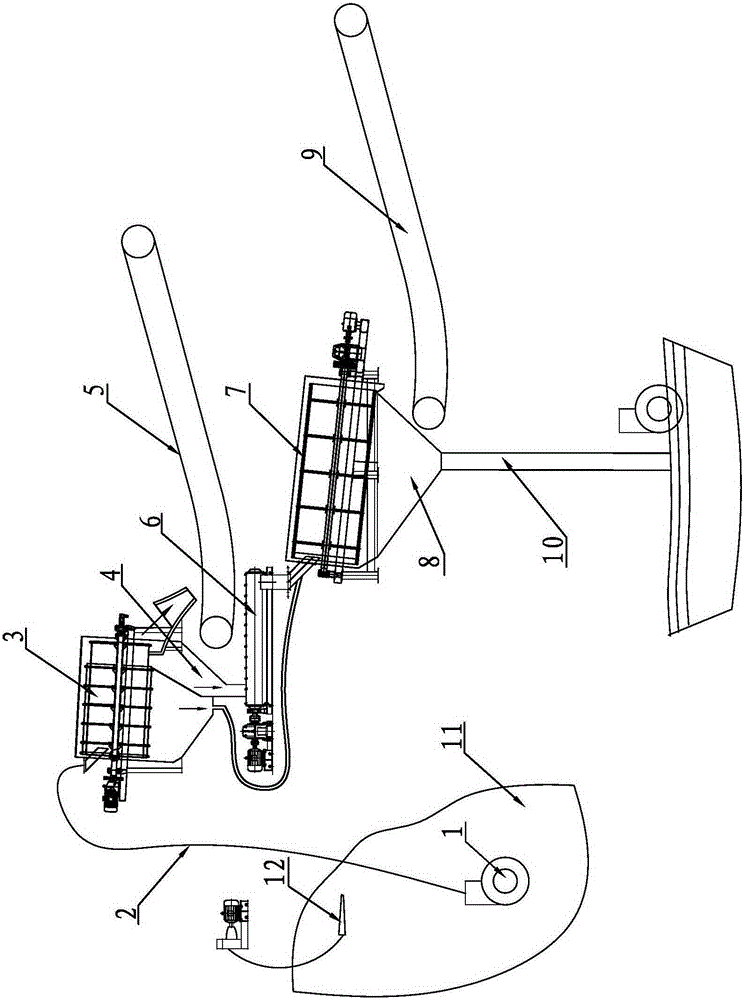

[0034] Embodiment 1: a kind of impurity method in removing lake and river silt, such as figure 1 with figure 2 Shown: It includes the following steps:

[0035] Step 1, the sludge is diluted, and the sludge taken out is washed and diluted with a high-pressure water gun 12 to ensure that the water content is 65% to 90%;

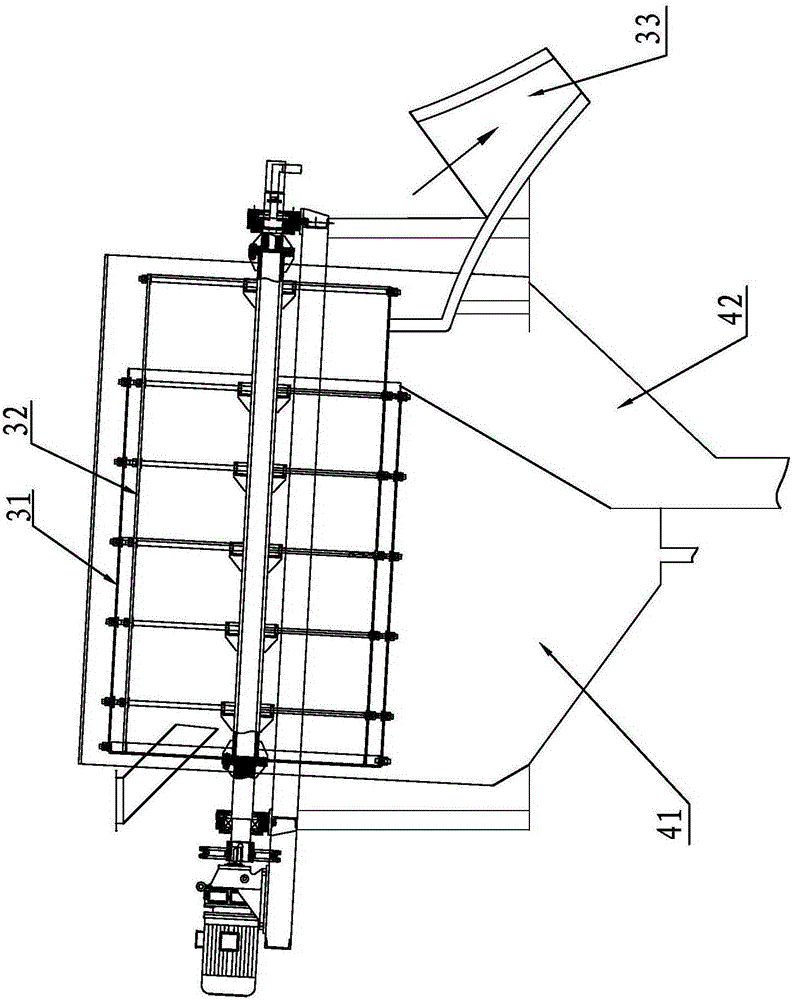

[0036] Step 2, use the mud pump 1 to input the diluted mud mixed slurry into the inner chamber of the inner layer drum screen 32 in the primary impurity removal drum screen 3, the mesh aperture of the inner layer drum screen 32 is 20-60 mm, and the outer layer drum screen The diameter of the mesh hole of 31 is 2-6 mm. By rotating the primary impurity removal drum screen 3, hard impurities such as snails, shells, stones, bricks and tiles, wooden rods, metal objects, waste glass, plastic blocks and other hard impurities in the sludge and Soft impurities such as plastic ropes, plastic nets, plastic bags and waste plastic paper are preliminarily removed, and the...

Embodiment 2

[0043] Embodiment 2: In the lake and river sludge removal complete set of equipment in embodiment 1, there is no high-pressure water spray device in the inner cavity of the primary impurity removal trommel 3 and the secondary impurity removal trommel 7, which is still effective, but only the impurity removal efficiency slightly lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com