Magnetic suspension horizontal shaft direct-driving type wind driven generator with five freedom degrees

A magnetic levitation bearing and magnetic levitation technology, which is applied to wind turbine components, wind turbines, wind turbines in the same direction as the wind, etc., can solve the problem that the wind turbine cannot achieve all five degrees of freedom suspension, the use and operation of the magnetic suspension bearing system High cost, inability to further reduce the cut-in wind speed, etc., to achieve broad market application prospects, low practical and operating costs, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

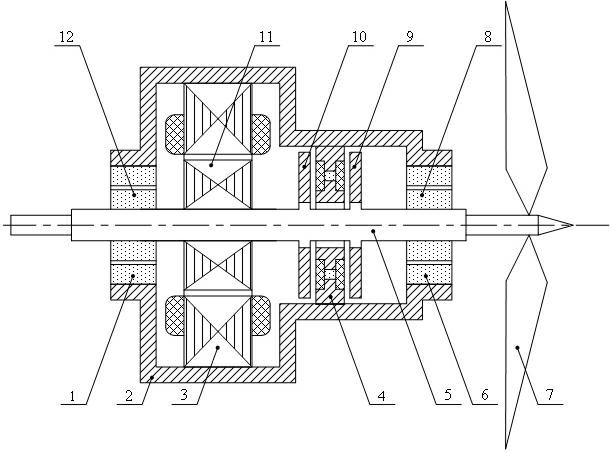

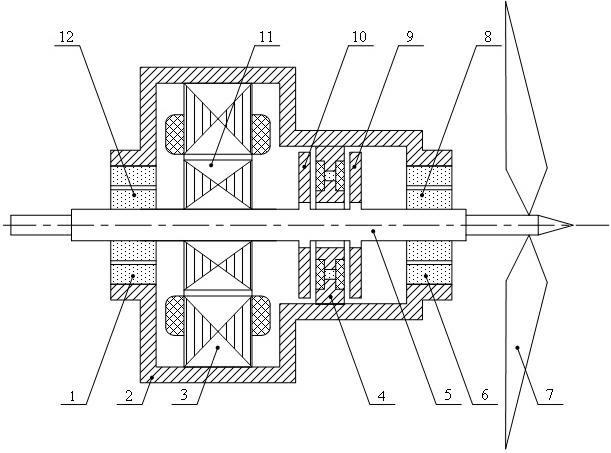

[0015] Such as figure 1 As shown, the permanent magnet type radial magnetic suspension bearing A stator 1, the generator stator 3, the permanent magnetic bias type axial magnetic suspension bearing stator 4, and the permanent magnetic radial magnetic suspension bearing B stator 6 are all fixed inside the housing 2, wherein, The generator stator 3 is located between the permanent magnet radial magnetic suspension bearing A stator 1 and the permanent magnet bias axial magnetic suspension bearing rotor B10, and the permanent magnet bias axial magnetic suspension bearing stator 4 is located between the permanent magnetic bias axial magnetic suspension bearing Between the bearing rotor B10 and the permanent magnet bias type axial magnetic suspension bearing rotor A9.

[0016] Permanent magnetic radial magnetic bearing A rotor 12, generator rotor 11, permanent magnetic bias axial magnetic bearing rotor A9, permanent magnetic bias axial magnetic bearing rotor B10, permanent magnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com