Miniature solid or hollow silicon needle, silicon needle array and preparing method thereof

A technology of needle array and hollow silicon, which is applied in the direction of microneedle, manufacturing microstructure device, semiconductor/solid-state device manufacturing, etc., can solve the problems of high production cost of micro hollow silicon needle, high start-up and maintenance cost, and high price, etc. Achieve the effect of low cost, simple manufacturing process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

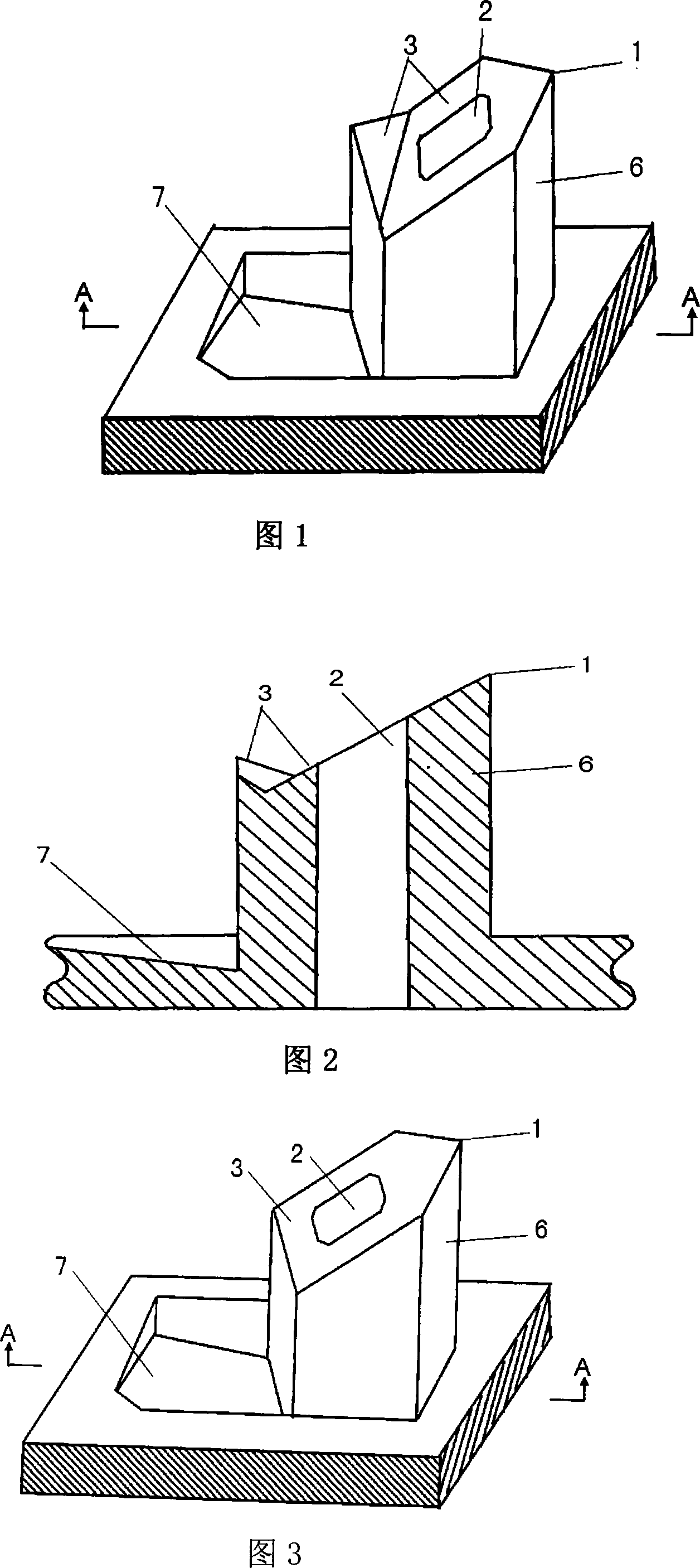

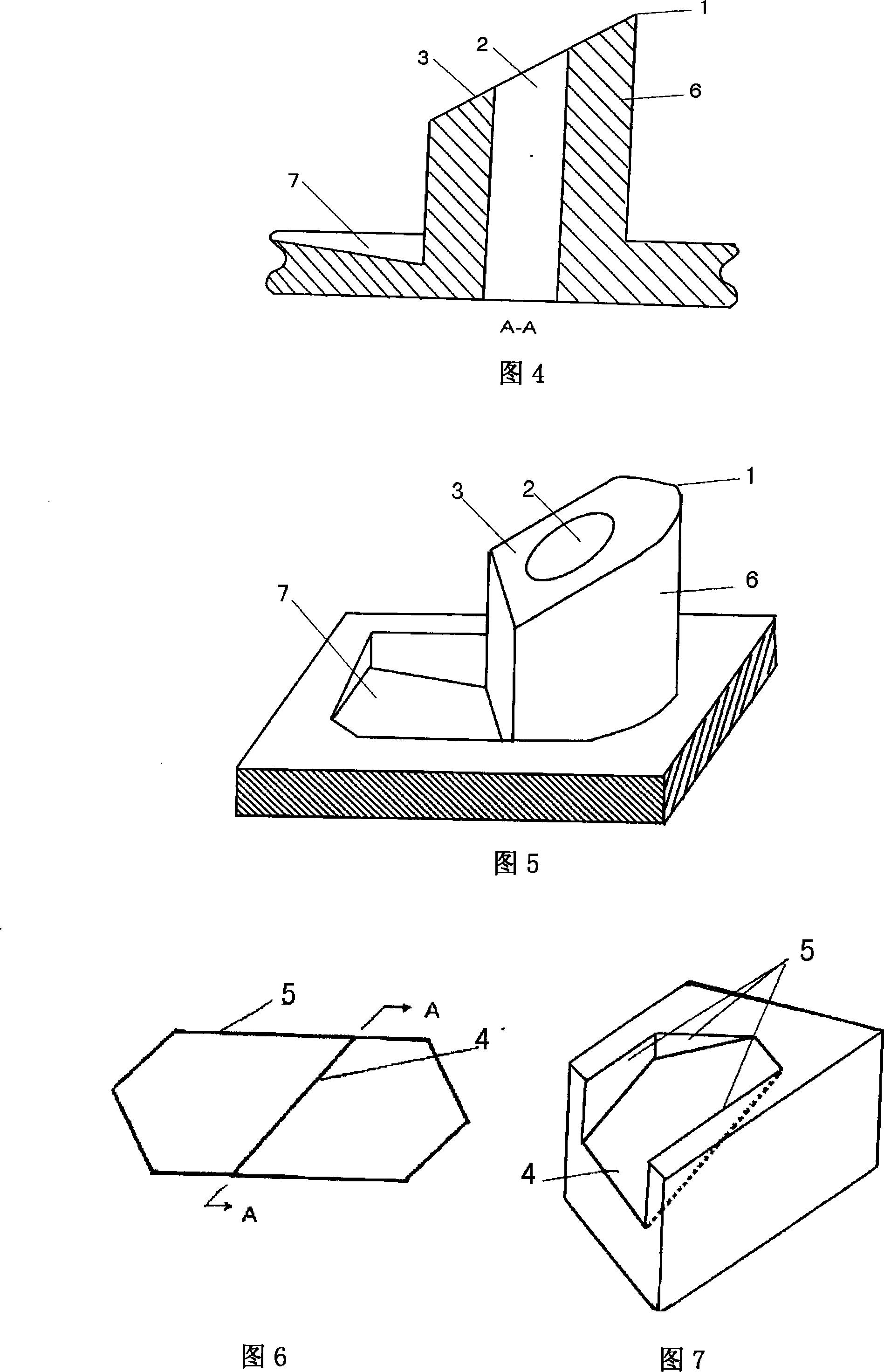

[0042] The invention proposes a miniature solid or hollow silicon needle array and a manufacturing method thereof. The present invention is described below in conjunction with accompanying drawing, the structure of described miniature solid or hollow silicon needle array is as follows:

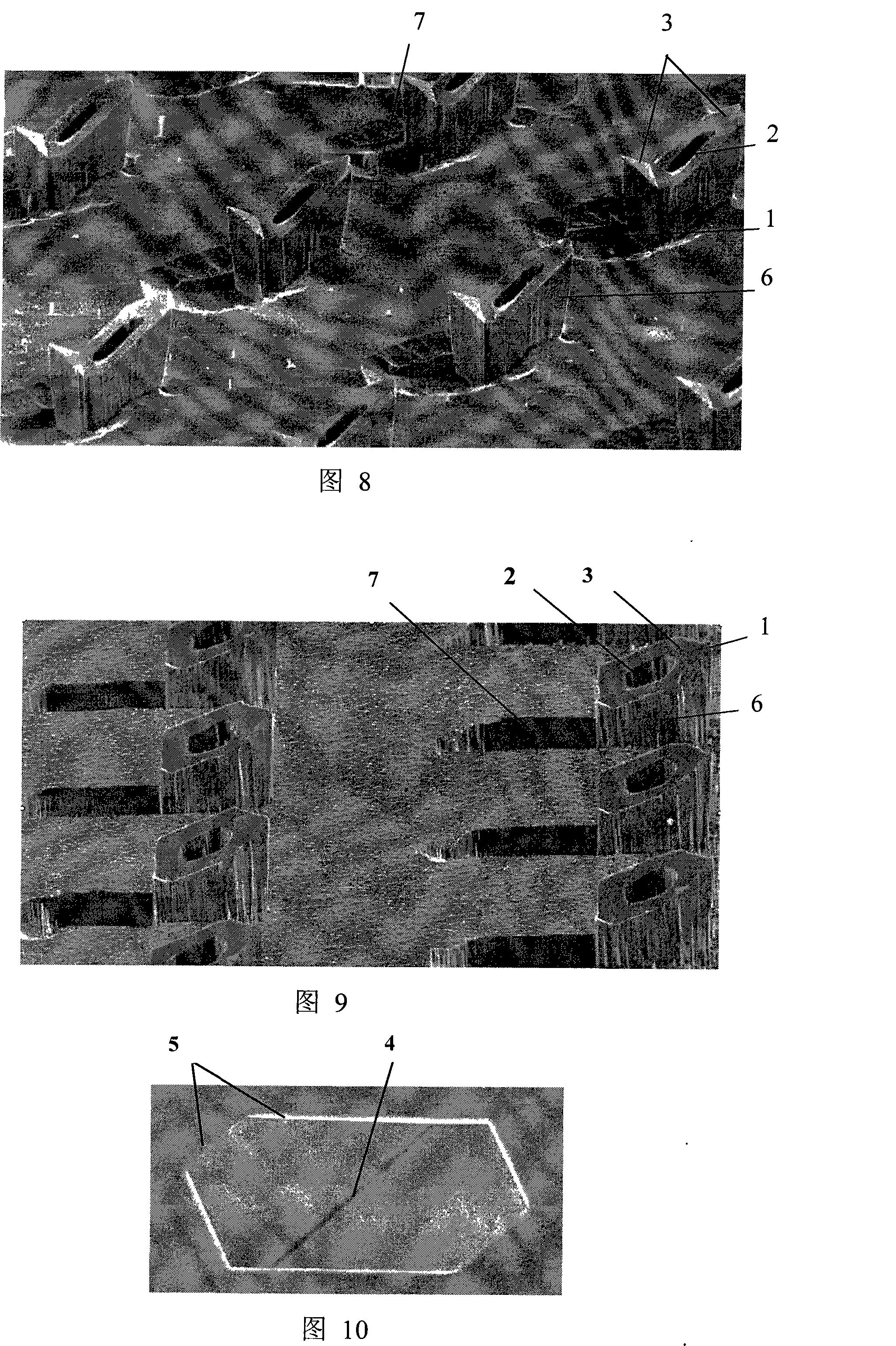

[0043] 1) The shape of the micro-silicon needle is similar to that of a traditional hypodermic needle. The lower end of the needle is a columnar body 6. There is at least one smooth slope 3 at the part where the needle tip is formed at the upper end of the needle. ) planes 5 are parallel; the bevel 3 is arc-shaped at the needle tip or has one or more sharp corners to form the apex 1 of the needle (as shown in Figures 1, 5, 8, and 9);

[0044] 2) There are polygonal, elliptical or circular holes 2 on the smooth slope 3 at the top of the needle tip, and these holes 2 and the bottom of the silicon needle are formed by six (111) surfaces 5 (as shown in Figures 6 and 10) The inverted triangular gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com