Plant three-dimensional measurement method and system based on PTZ camera system parameters and video frames

A system parameter and three-dimensional measurement technology, applied in the direction of measuring devices, instruments, optical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

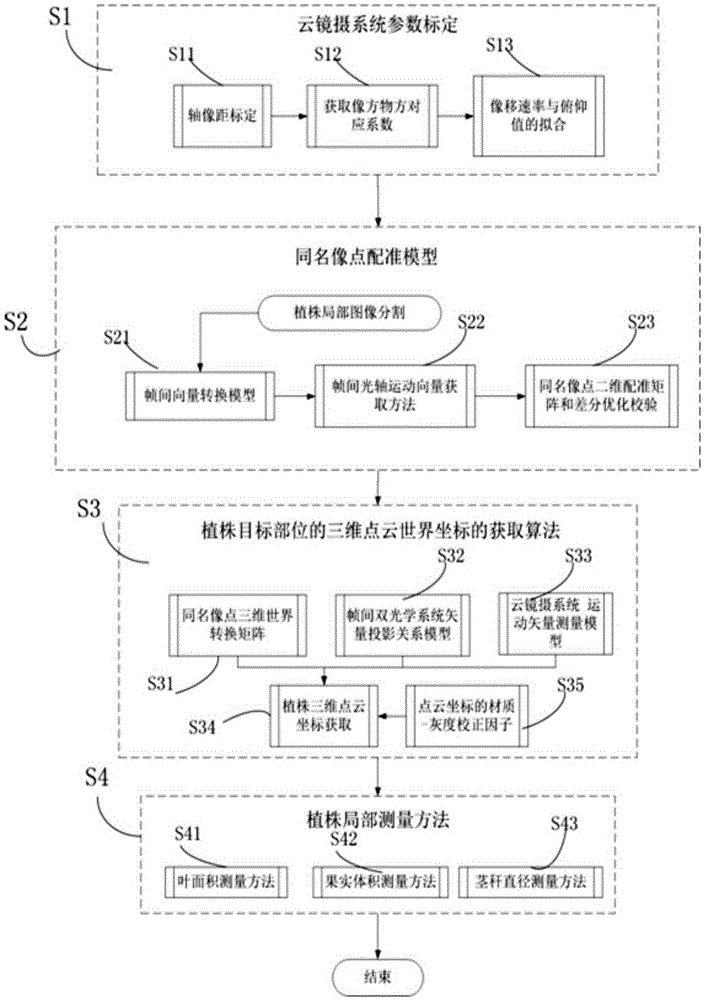

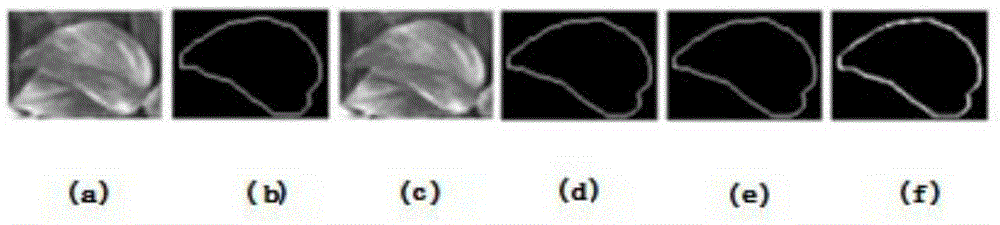

[0027] Such as figure 1 As shown, the plant three-dimensional measurement method based on cloud mirror camera system parameters and video frames provided by the embodiment of the present invention includes the following steps:

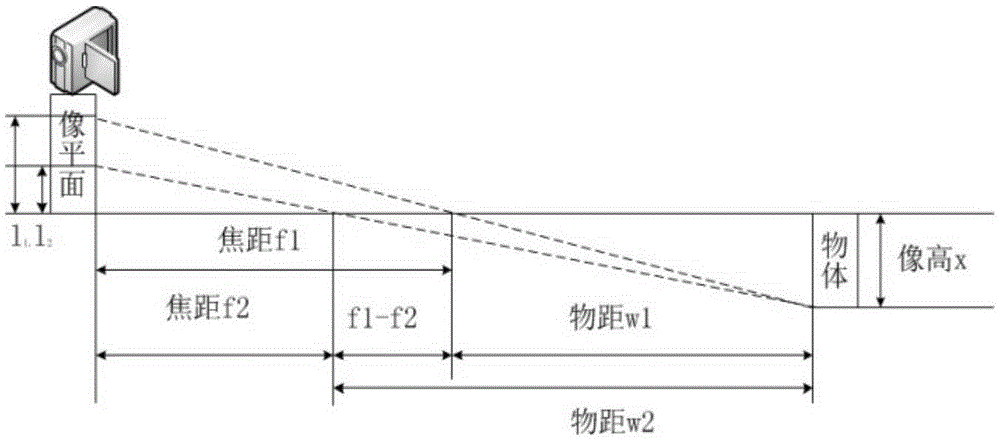

[0028] S1. to the demarcation method of cloud mirror photographing system external parameter, its preferred step comprises: measure the axial image distance of cloud mirror photographing system, promptly the distance of the center of the center of the axis site of image acquisition equipment and image plane; Solving image square and object The method of square corresponding coefficient; establish the fitting equation between the image motion rate val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com