All-natural putty for interior walls of constructions

A purely natural technology in the building, applied in the direction of filling slurry, etc., can solve the problems of complex process and high cost, and achieve the effects of high purity and whiteness, strong hiding power, good activity and cementation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

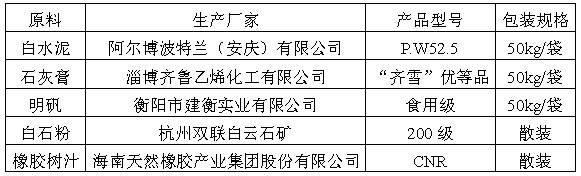

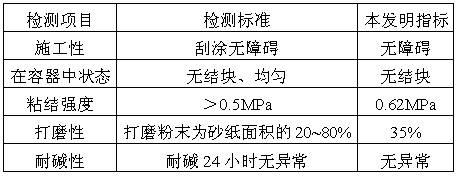

Method used

Image

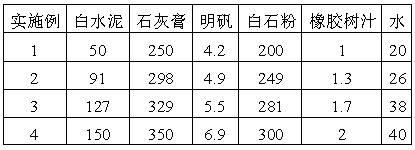

Examples

Embodiment Construction

[0015] The inventive method implements according to the following steps:

[0016] (1) Use a pulverizer to crush white stone powder and alum into fine particles.

[0017] (2) Mix white cement and lime paste and put them into the mixer, then put crushed white stone powder and alum in a certain proportion, then add rubber tree sap and stir evenly for 70-150 seconds.

[0018] (3) The mixed dry solid after stirring and discharging is then prepared into a thick liquid product through the step of adding water.

[0019] Construction operation steps of the present invention:

[0020] After cleaning the inner wall, sprinkle water on the wall 5 days in advance when the temperature is 2~10℃; sprinkle water on the wall 3 days in advance when the temperature is 10~25℃; sprinkle water on the wall 1 day in advance when the temperature is above 25℃ . In the first pass, use cement to mix mortar to make a primer (the mud content is not more than 5%), then mix a certain proportion of water wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com