Anti-channeling well cementation resin cement paste and application thereof

A cement slurry and resin technology, which is applied in the field of anti-channeling cementing resin cement slurry, can solve problems such as the adverse effects of fracturing and stratified mining, affecting the production of natural gas wells, and reducing the recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the present invention, the preparation method of described water-soluble epoxy resin preferably comprises the following steps:

[0034] (1) Mix propylene oxide butyl ether, butyl acrylate, phloroglucinol and deionized water to carry out polycondensation reaction to obtain an epoxy resin precursor; the temperature of the polycondensation reaction is 80-90° C. The time is 3.5 ~ 4.5h;

[0035] (2) Mix the epoxy resin precursor obtained in the step (1) with an alkaline solution, and react to obtain a reaction feed liquid; the temperature of the reaction is 85 to 90° C., and the reaction time is 2 to 4 hours;

[0036] (3) washing and drying the reaction feed liquid obtained in the step (2) successively to obtain a solid resin;

[0037] (4) mixing the solid resin obtained in the step (3) with an organic solvent to obtain a water-soluble epoxy resin.

[0038] In the present invention, the mass ratio of the propylene oxide butyl ether, butyl acrylate, phloroglucinol and de...

Embodiment 1

[0054] Add 10 parts by weight of propylene oxide butyl ether, 10 parts by weight of butyl acrylate, 35 parts by weight of phloroglucinol, and 25 parts by weight of deionized water into the reactor, react at 80 ° C for 3 hours, and react Cool to 40°C after completion, then add 5 parts by weight of 30wt% sodium hydroxide solution to it, further react at 85°C for 2.5h, wash the obtained material with water after cooling, and then dry at 80°C for 30 minutes to reduce the moisture content. If it is less than 5%, solid resin particles are obtained, and half of the mass of solid resin is added to dissolve in ethanol to obtain liquid epoxy resin.

[0055] The obtained water-soluble epoxy resin has high toughness, and the impact strength reaches 65KJ / m 2 , the strength of the water-soluble epoxy resin after curing reaches 70MPa.

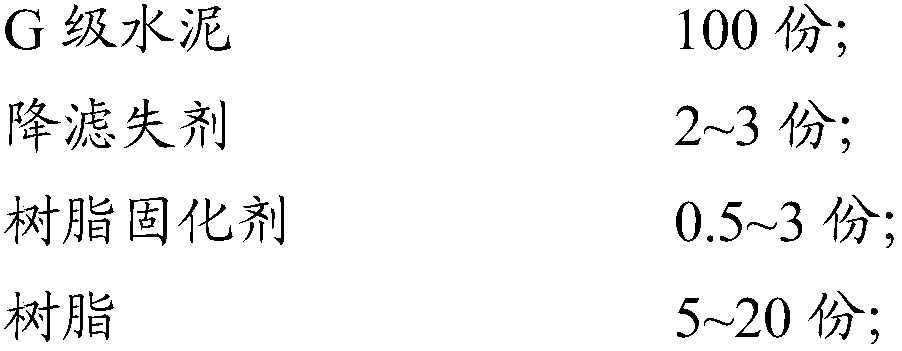

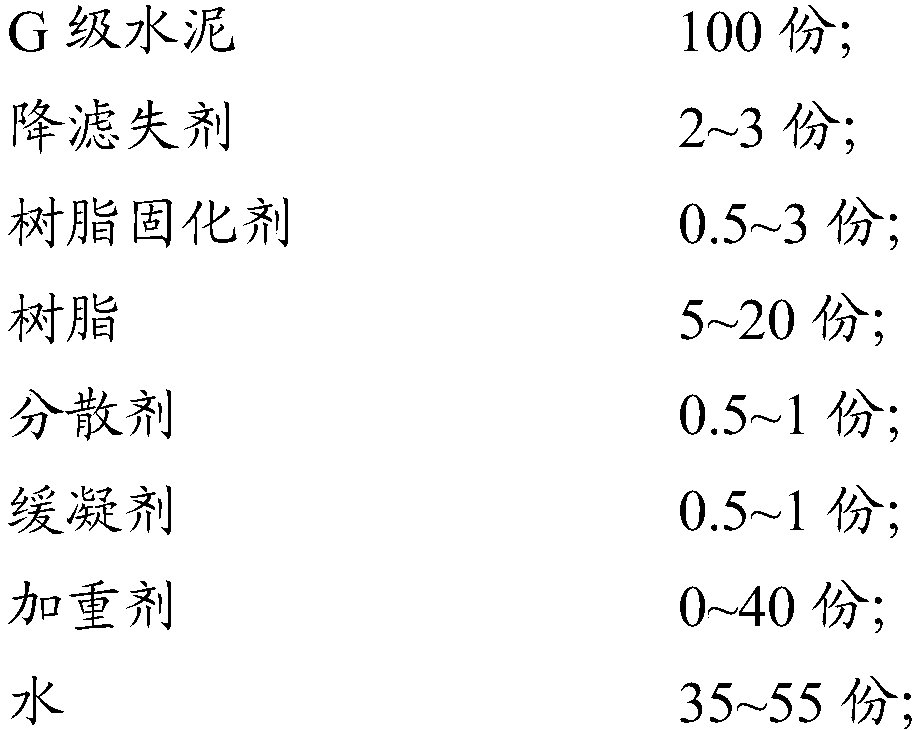

[0056] Preparation of anti-channeling cementing resin cement slurry: based on the weight of 100% G-grade cement, the percentage of each additive to the weig...

Embodiment 2

[0058] Add 20 parts by weight of propylene oxide butyl ether, 10 parts by weight of butyl acrylate, 30 parts by weight of phloroglucinol, and 20 parts by weight of deionized water into the reactor in proportion, and react at 85°C for 3h, and react Cool to 40°C after completion, then add 6 parts by weight of 30wt% sodium hydroxide solution therein, further react for 3h at 80°C, wash the material after cooling, then dry at 80°C for 30 minutes to make the water content less than 5% to obtain solid resin particles, and then add half of the solid resin mass in ethanol to dissolve to obtain liquid epoxy resin.

[0059] The water-soluble epoxy resin has high toughness, and the impact strength reaches 65KJ / m 2 , the maximum strength of the water-soluble epoxy resin after curing can reach 70MPa.

[0060] Preparation of anti-channeling cementing resin cement slurry: based on the weight of 100% G-grade cement, the percentage of each additive in G-grade cement weight is: AMPS and AA copo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com