Method for manufacturing biomass fuel

A technology of biomass fuel and manufacturing method, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problem of harmful gas generation, achieve the effects of reducing power consumption, reducing maintenance costs, and increasing product density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

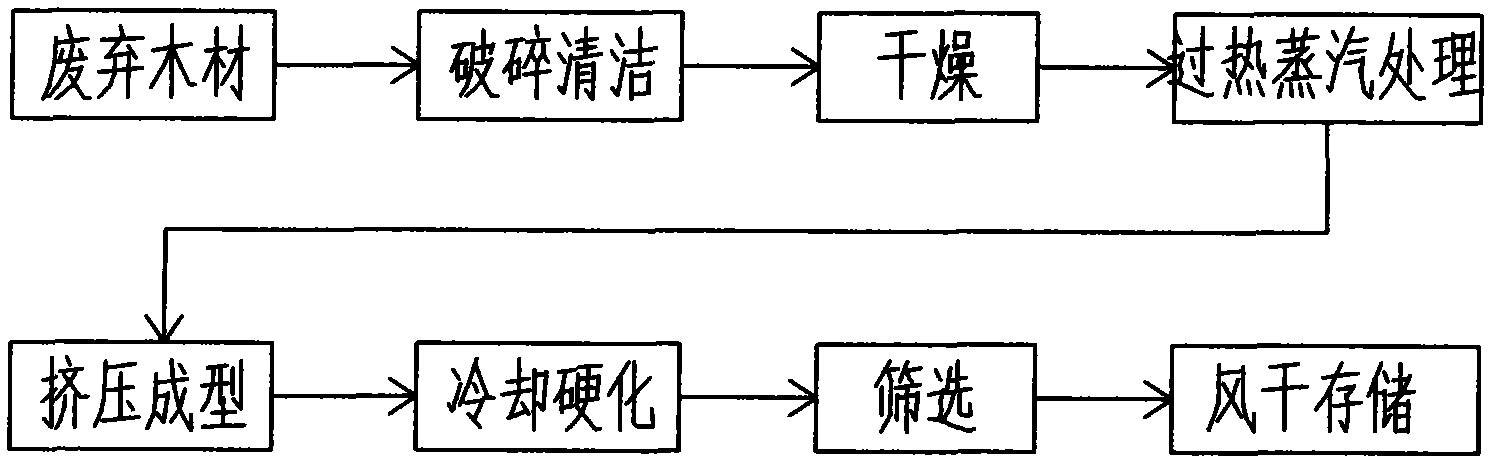

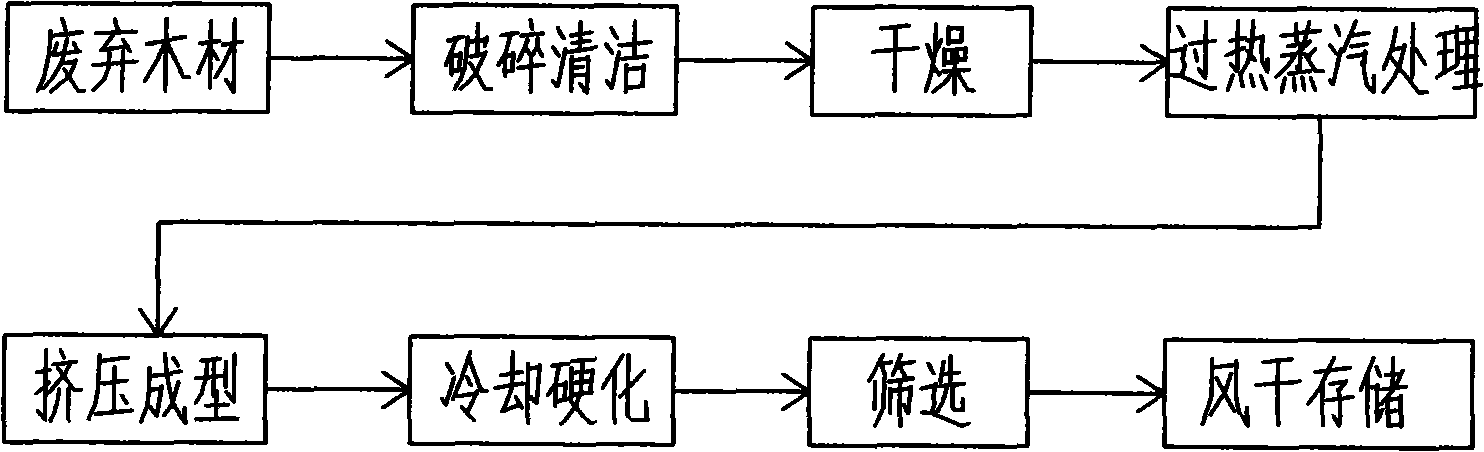

[0021] The specific implementation of the biomass fuel production method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 Shown, biomass fuel manufacturing method of the present invention, comprises process step as follows:

[0023] a. Crush and clean the waste wood, remove impurities, and obtain raw materials with a particle size between φ0.02mm-φ20mm; the purchased waste wood materials contain certain metals, plastics and other sundries, which can be removed after crushing and cleaning , and obtain raw materials of suitable size. When producing high-density biomass fuels with a density greater than 1g / cm3, the particle size of the raw materials should be controlled between φ0.02mm-φ6mm. When producing high-density biomass fuels with a density less than 1g / cm3 , the particle size of the raw material is between φ6mm-φ20mm;

[0024] b. Dry the wood chips so that their moisture content i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com