Machined carbon-free corundum spinel brick for ladles and preparation method thereof

A technology of spinel brick and carbon corundum, which is applied in the field of machine-pressed carbon-free corundum spinel brick for ladle and its preparation, can solve the problems of poor thermal shock stability, low strength at room temperature, molten steel pollution, etc., and achieve good cementation The effect of low thermal conductivity, low thermal conductivity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

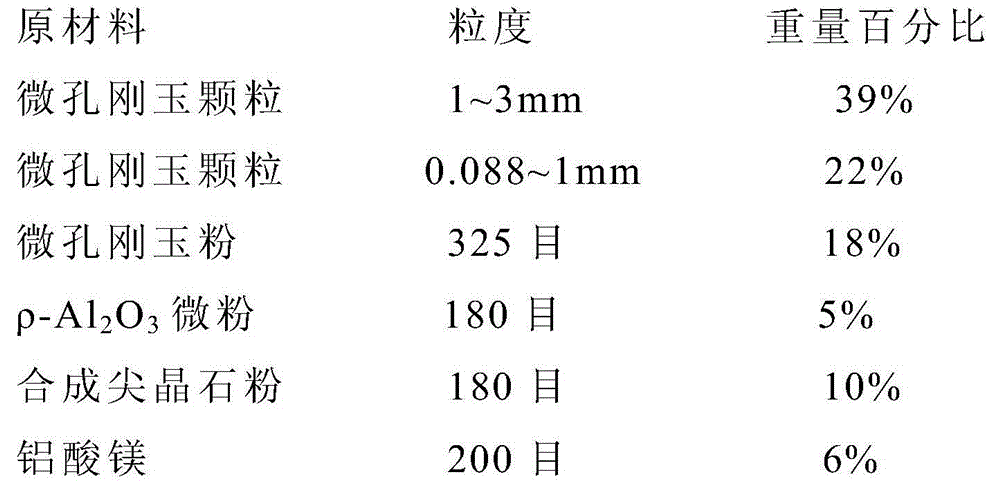

[0022] Machine-pressed carbon-free corundum spinel bricks for ladle, calculated by weight percentage, its raw material ratio is as follows:

[0023]

[0024]

[0025] After mixing the solid raw materials in proportion, add water, mix and grind them with a mixer, then put them into a brick press for molding, heat treatment at 200°C for 24 hours, and finally select, inspect, pack, and put them into storage to produce ladle machines. Pressed carbon-free corundum spinel bricks.

Embodiment 2

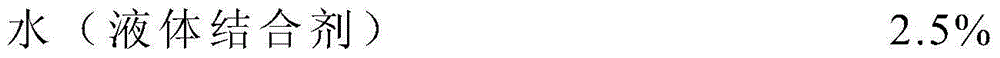

[0027] Machine-pressed carbon-free corundum spinel bricks for ladle, calculated by weight percentage, its composition ratio is as follows:

[0028]

[0029] After mixing the solid raw materials in proportion, add water, mix and grind them in a mixer mill, then put them into a brick press for molding, heat treatment at 220°C for 20 hours, and finally select, inspect, pack, and put them into storage to produce ladle machines. Pressed carbon-free corundum spinel bricks.

Embodiment 3

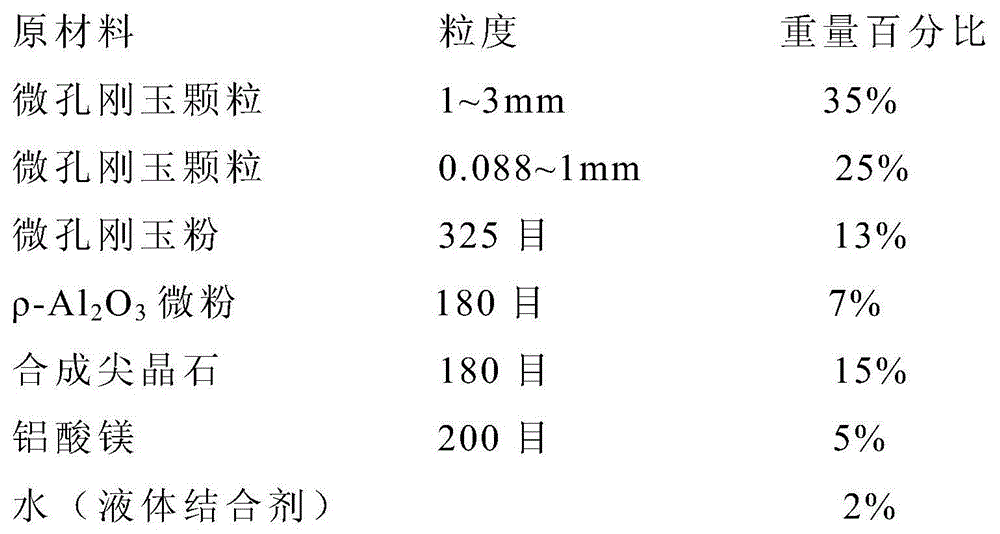

[0031] Machine-pressed carbon-free corundum spinel bricks for ladle, calculated by weight percentage, its composition ratio is as follows:

[0032]

[0033]

[0034] After mixing the solid raw materials in proportion, add water, mix and grind them with a mixer, then put them into a brick press for molding, heat treatment at 170°C for 30 hours, and finally select, inspect, pack, and put them into storage to produce ladle machines. Pressed carbon-free corundum spinel bricks.

[0035] The main physical and chemical indicators of the machine-pressed carbon-free corundum spinel brick product obtained in Examples 1 to 3 of the present invention:

[0036] Bulk density after baking at 200℃ (200℃×24h) ≥ 3.0g / cm;

[0037] Apparent porosity (200℃×24h)≤12%;

[0038] Compressive strength (200℃×24h)≥50MPa;

[0039] Linear change rate (1600℃×3h) 0~1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com