Sewer decomposer

A decomposer and sewer technology, which is applied in water supply installations, indoor sanitation pipeline installations, buildings, etc., can solve the problems of no real solution to the overflow of sewer odor gas, the inability to completely seal the sewer odor, and the inability to achieve complete sealing, etc., reaching a wide range Use value, good plugging effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

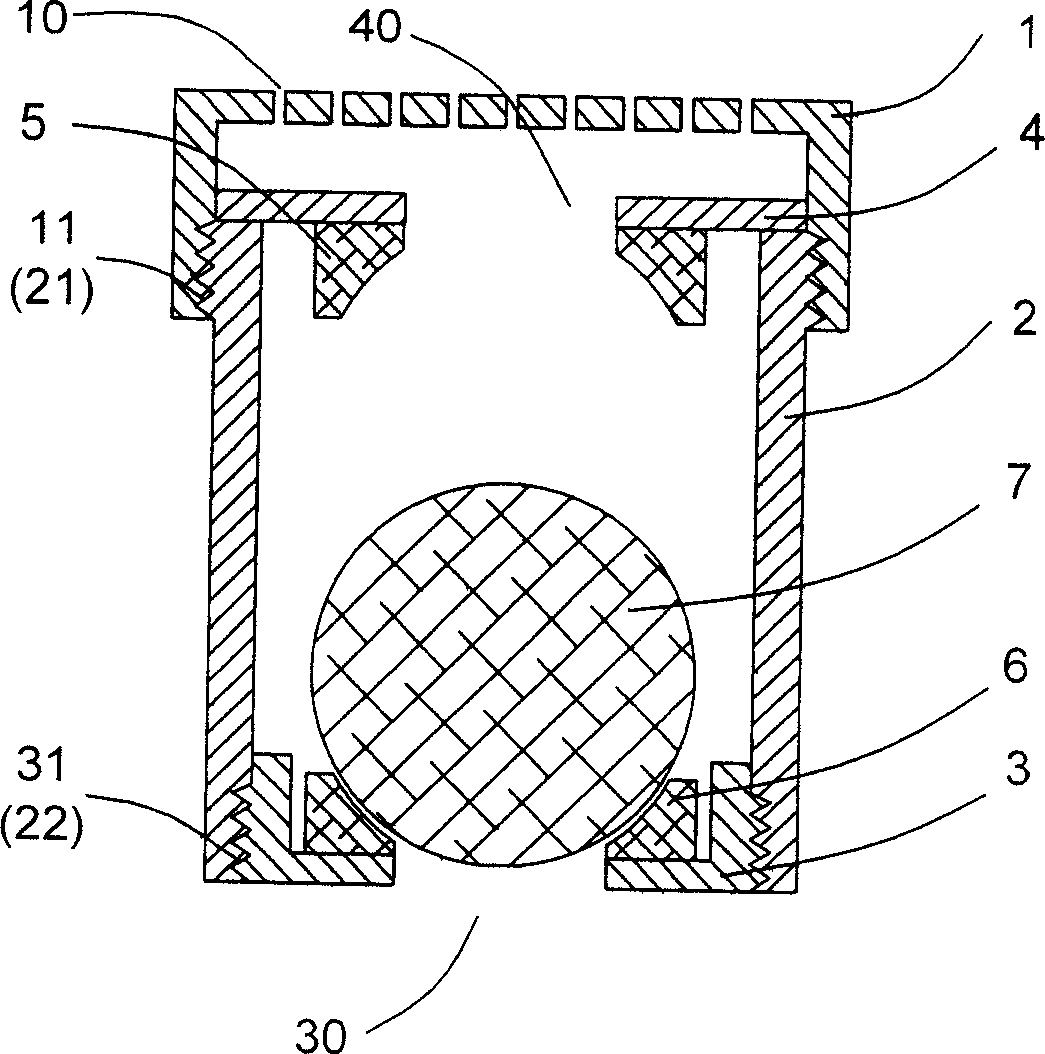

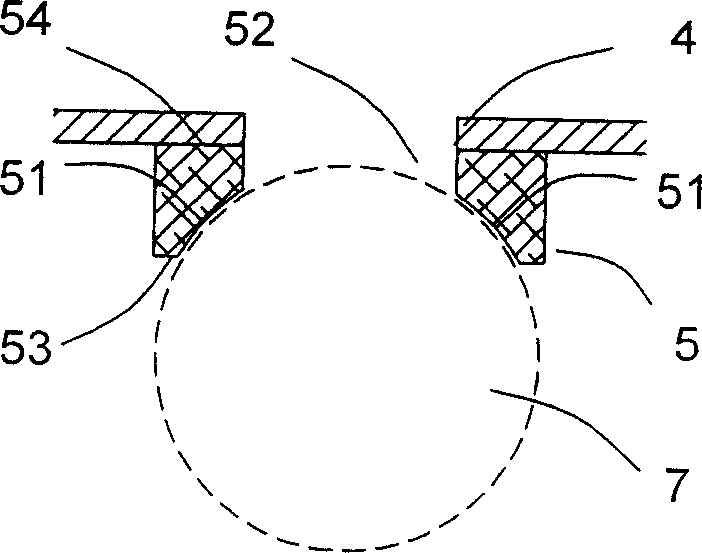

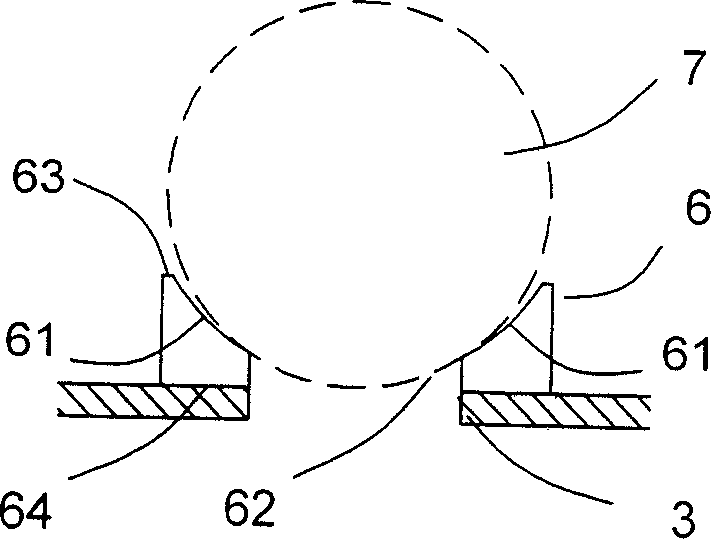

[0031] figure 1 It is a structural sectional view of the sewer decomposer of the present invention. Such as figure 1 As shown, the water inlet end cap 1, the float chamber 2 and the water outlet end cap 3 are connected in turn to form the main structure of the present invention, wherein the float chamber 2 is a hollow cylinder, and the water inlet end cap 1 and the water outlet end cap 3 are respectively connected to the At the two ends of the floating ball chamber 2, the floating ball 7 is arranged in the hollow body of the floating ball chamber 2. A partition 4 with the same cross-sectional shape is fixedly connected to the water inlet end cover 1 , and a water inlet 40 is arranged at the center of the water inlet end cover 1 and the partition 4 . In this embodiment, the end face of the water inlet end cover 1 is provided with a filter sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com