Concrete curing agent, preparation method and application thereof

A technology of concrete curing agent and construction method, which is applied in the field of concrete curing agent and its preparation, which can solve the problems of large damage and achieve the effects of preventing sanding, improving impermeability and stain resistance, and increasing strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Formula: 1% potassium silicate with a modulus of 5, 0.01% polyethylene oxide, 0.5% octyltriethoxysilane, 0.5% lignosulfonate surfactant, 0.3% polyvinyl acetate emulsion, and the balance is water.

[0029] Preparation method: Mix the components in the above formula evenly according to the above mass percentages, and stir to prepare the concrete curing agent.

[0030] Application: 1) Polish the concrete floor with 50-mesh and 300-mesh sand mills, and clean the floor;

[0031] 2) Dilute the curing agent of the present invention by 1 to 2 times and brush the concrete floor;

[0032] 3) After the concrete floor is dry, polish it with 500-mesh and 1000-mesh polishing machines respectively to obtain a concrete floor with high hardness and high gloss.

Embodiment 2

[0034] Formula: Potassium silicate with a modulus of 5.5 30%, polyethylene oxide 0.5%, octyltriethoxysilane 0.5%, octyltriethoxysilane aqueous emulsion 1%, naphthalenesulfonate 1%, butylbenzene Emulsion 1%, balance water.

[0035] The preparation method and application method of the concrete curing agent are the same as in Example 1.

Embodiment 3

[0037] Formula: 15% of potassium silicate with a modulus of 6, 0.2% of organosiloxane condensation polymer, 1% of octyltriethoxysilane aqueous emulsion, 0.8% of sulfonated melamine formaldehyde resin, 0.6% of propylene benzene emulsion, and the balance is water.

[0038] The preparation method and application method of the concrete curing agent are the same as in Example 1.

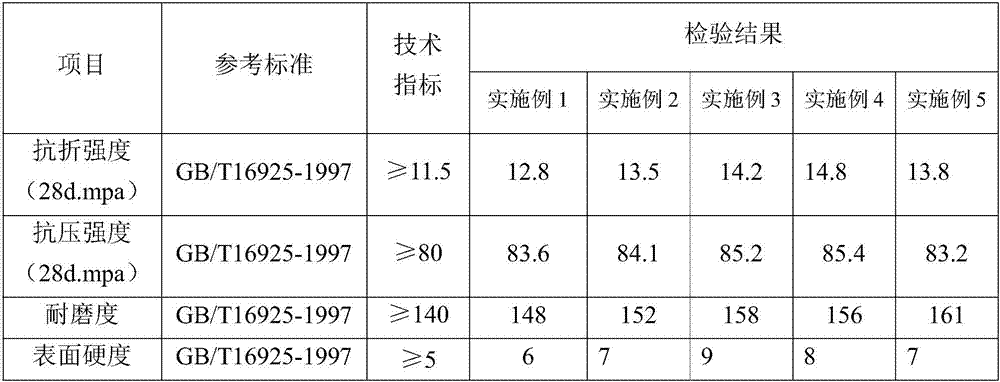

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com