Test container for imitating deep-sea high-pressure environment

A high-pressure environment and container technology, applied to pressure vessels, using stable tension/pressure to test the strength of materials, fixed-capacity gas storage tanks, etc., can solve problems such as damage to the container's sealed state, achieve convenient disassembly of equipment, and broad application prospects , Increase the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

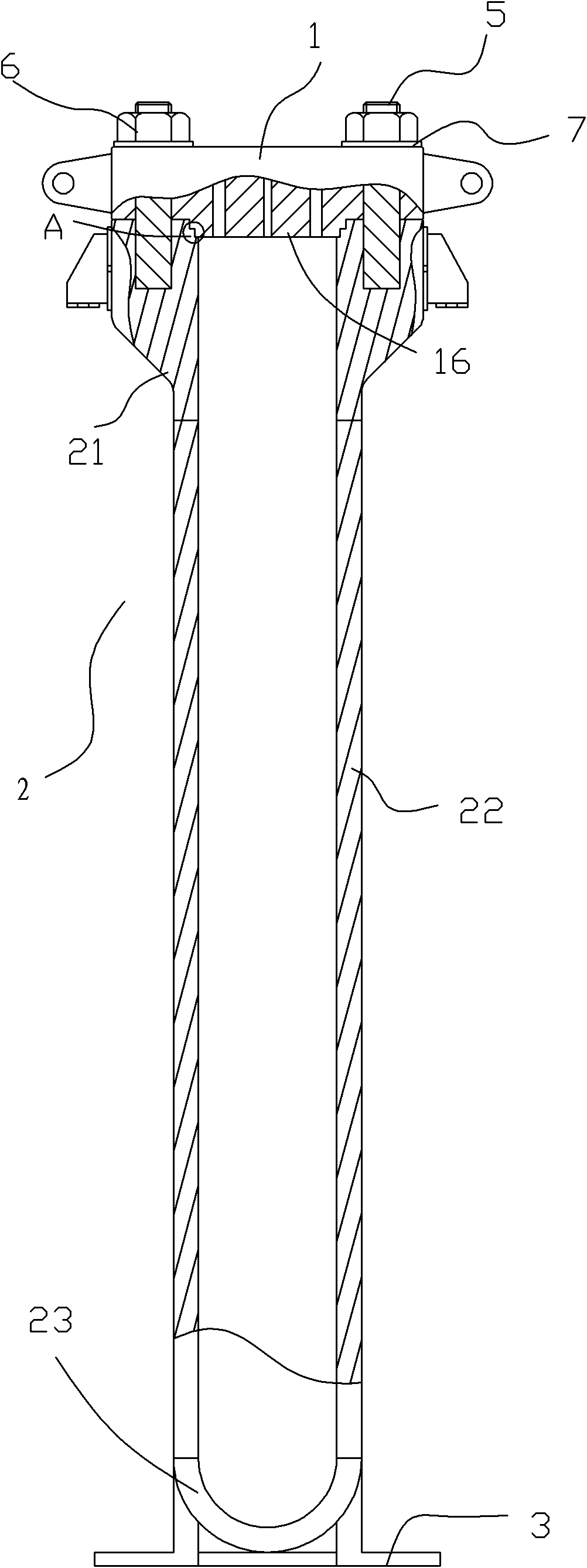

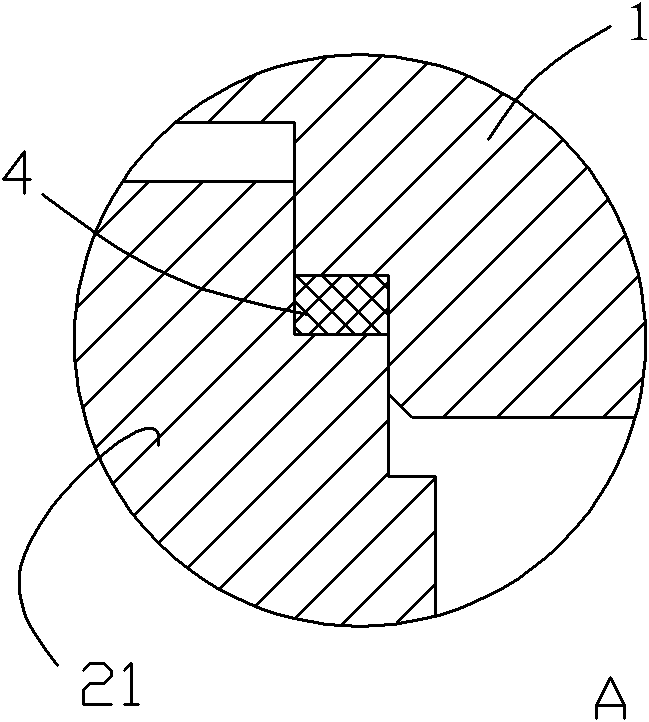

[0017] As shown in the figure, a test container simulating a high-pressure marine environment includes a container body 2 and a flat cover 1. The container body 2 is welded by a joint 21 at the head, a test cylinder 22 in the middle, and a seal 23 at the bottom. They are all made of steel, and the thickness of the test cylinder 22 and the head 23 reaches 27 mm. The cross section of the head 23 and the test cylinder 22 is circular, and the inner wall surface of the head 23 is a hemispherical surface, so that the test cylinder 22 and the head 23 are tangent at the welding point, and there are no edges and corners, so there is no weakened strength. problem. The bottom of the container body 2 is also provided with a skirt 3 for supporting it, and a threaded hole is provided on the skirt of the skirt 3 for fixed connection with the ground.

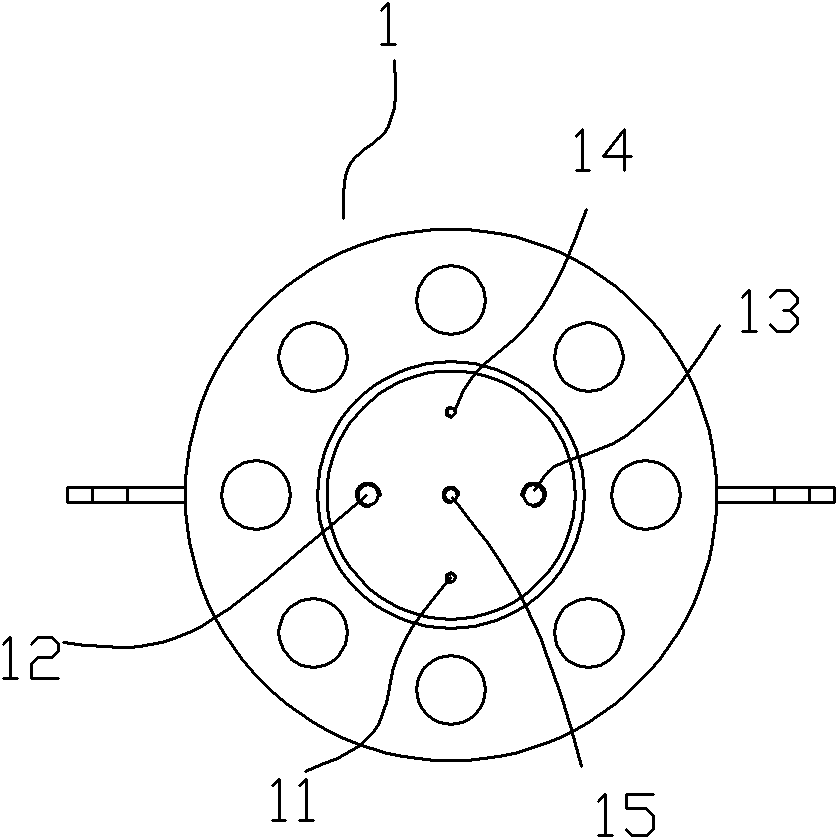

[0018] The top surface of the flat cover 1 is provided with a vertically penetrating water injection hole 11, a pressure measuring hole 12, a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com