Method for preparing gradient nanostructure nitride layer on surface of titanium alloy

A nanostructure, surface gradient technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of effective control, etc., to achieve enhanced lubrication and wear resistance, effective shape and size, widening The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

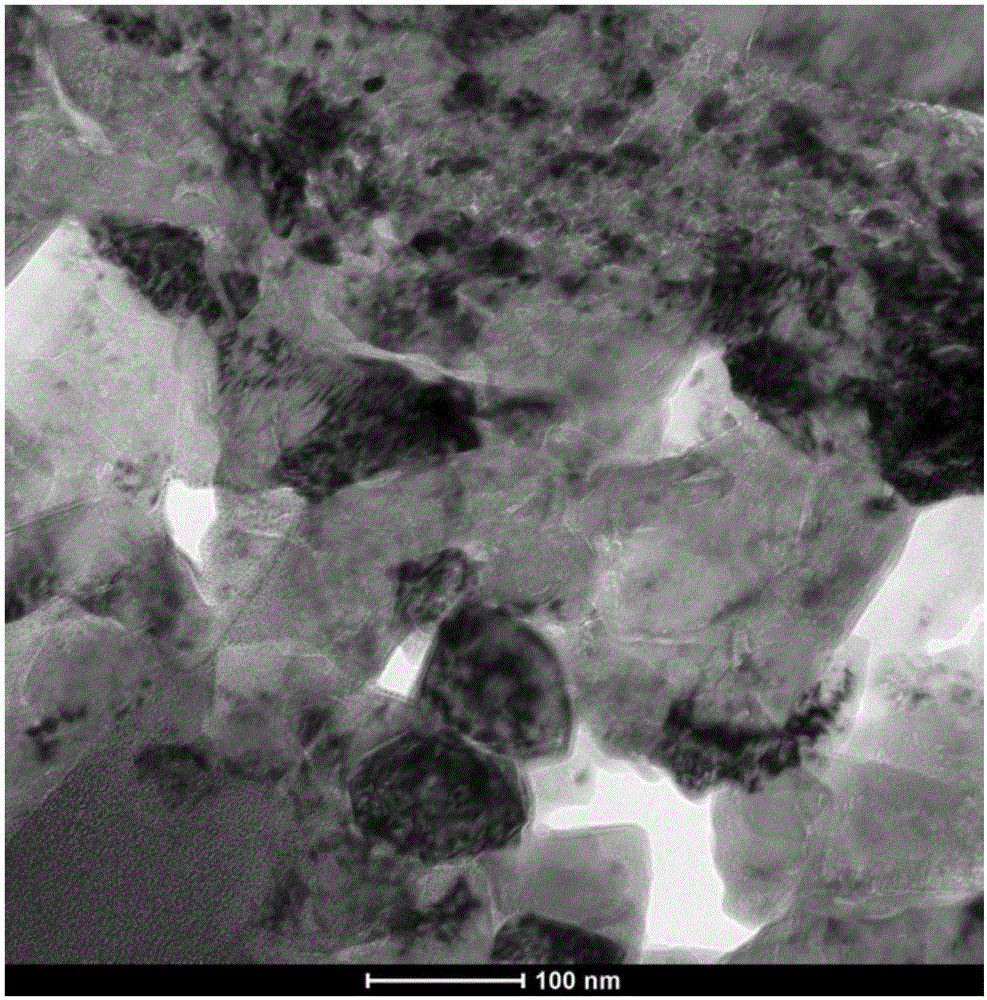

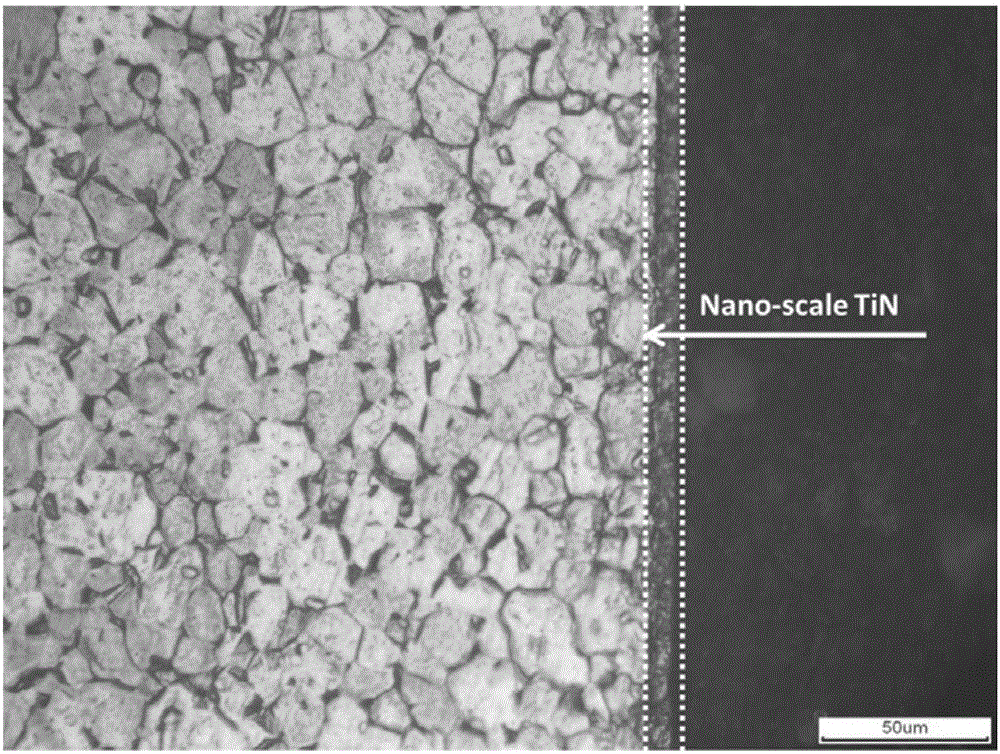

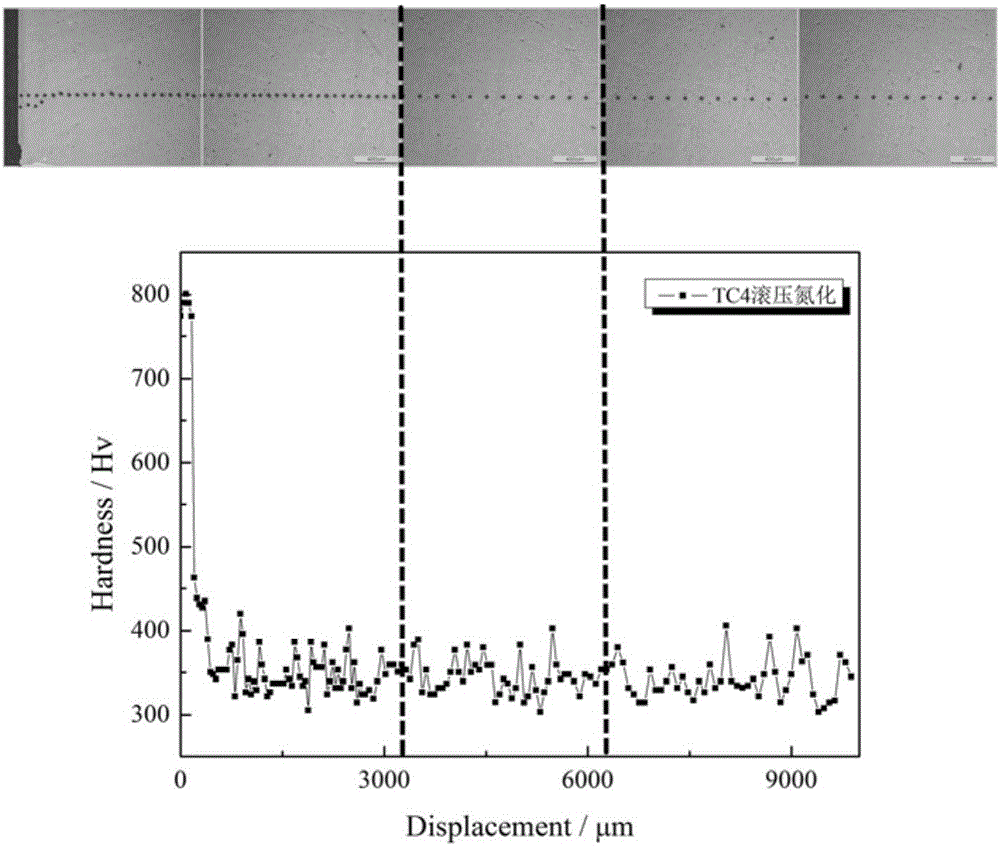

[0028] Such as Figure 1 ~ Figure 4 As shown, a method for preparing a gradient nanostructure nitride layer on the surface of a titanium alloy comprises the following steps:

[0029] (1) The titanium alloy is first subjected to vacuum high-temperature annealing treatment. The temperature of high-temperature annealing is 700-705 ° C, and the time is 1 hour. After the vacuum furnace is cooled to room temperature, the titanium alloy is taken out, and then the surface is polished to a smooth, smooth and smooth surface with a grinder. No scratches, then clean the surface with petroleum ether and alcohol, and dry it naturally for later use; wherein, the titanium alloy is (α+β) type TC4 titanium alloy, which consists of the following components and weight percentage content: Al 5.5wt %, V 3.5wt%, Fe 0.1wt%, C0.02wt%, N 0.01wt%, H 0.005wt%, O 0.1wt%, the balance being Ti.

[0030] (2) Install the ultrasonic rolling processing device, set the ultrasonic rolling process parameters, app...

Embodiment 2

[0035] Such as Figure 1 ~ Figure 4 As shown, a method for preparing a gradient nanostructure nitride layer on the surface of a titanium alloy comprises the following steps:

[0036](1) The titanium alloy is first subjected to vacuum high-temperature annealing treatment. The temperature of high-temperature annealing is 840-850°C for 4 hours. After cooling to room temperature in the vacuum furnace, the titanium alloy is taken out, and then the surface is polished to a smooth, smooth and smooth surface with a grinder. No scratches, then clean the surface with petroleum ether and alcohol, and dry it naturally for later use; wherein, the titanium alloy is (α+β) type TC4 titanium alloy, which consists of the following components and weight percentage content: Al 6.8wt %, V 4.5wt%, Fe 0.3wt%, C0.10wt%, N 0.05wt%, H 0.015wt%, O 0.2wt%, and the balance is Ti.

[0037] (2) Install the ultrasonic rolling processing device, set the ultrasonic deep rolling process parameters, apply lubri...

Embodiment 3

[0040] Such as Figure 1 ~ Figure 4 As shown, a method for preparing a gradient nanostructure nitride layer on the surface of a titanium alloy comprises the following steps:

[0041] (1) The titanium alloy is first subjected to vacuum high-temperature annealing treatment. The temperature of high-temperature annealing is 740-750°C for 2 hours. After cooling to room temperature in the vacuum furnace, the titanium alloy is taken out, and then the surface is polished to a smooth, smooth and smooth surface with a grinder. No scratches, then clean the surface with petroleum ether and alcohol, and dry it naturally for later use; wherein, the titanium alloy is a (α+β) type TC4 titanium alloy, which consists of the following components and weight percentages: Al 6.0wt %, V 3.8wt%, Fe 0.15wt%, C 0.04wt%, N 0.02wt%, H 0.008wt%, O 0.14wt%, and the balance is Ti.

[0042] (2) Install the ultrasonic deep rolling processing device, set the ultrasonic deep rolling process parameters, apply l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeable layer thickness | aaaaa | aaaaa |

| Permeable layer thickness | aaaaa | aaaaa |

| Permeable layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com