Lead bullion granulation automation line production process and apparatus

A technology of automatic production and production methods, applied in the direction of mold extrusion granulation, etc., can solve the problems of loss of lead material, waste of energy, pollution of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

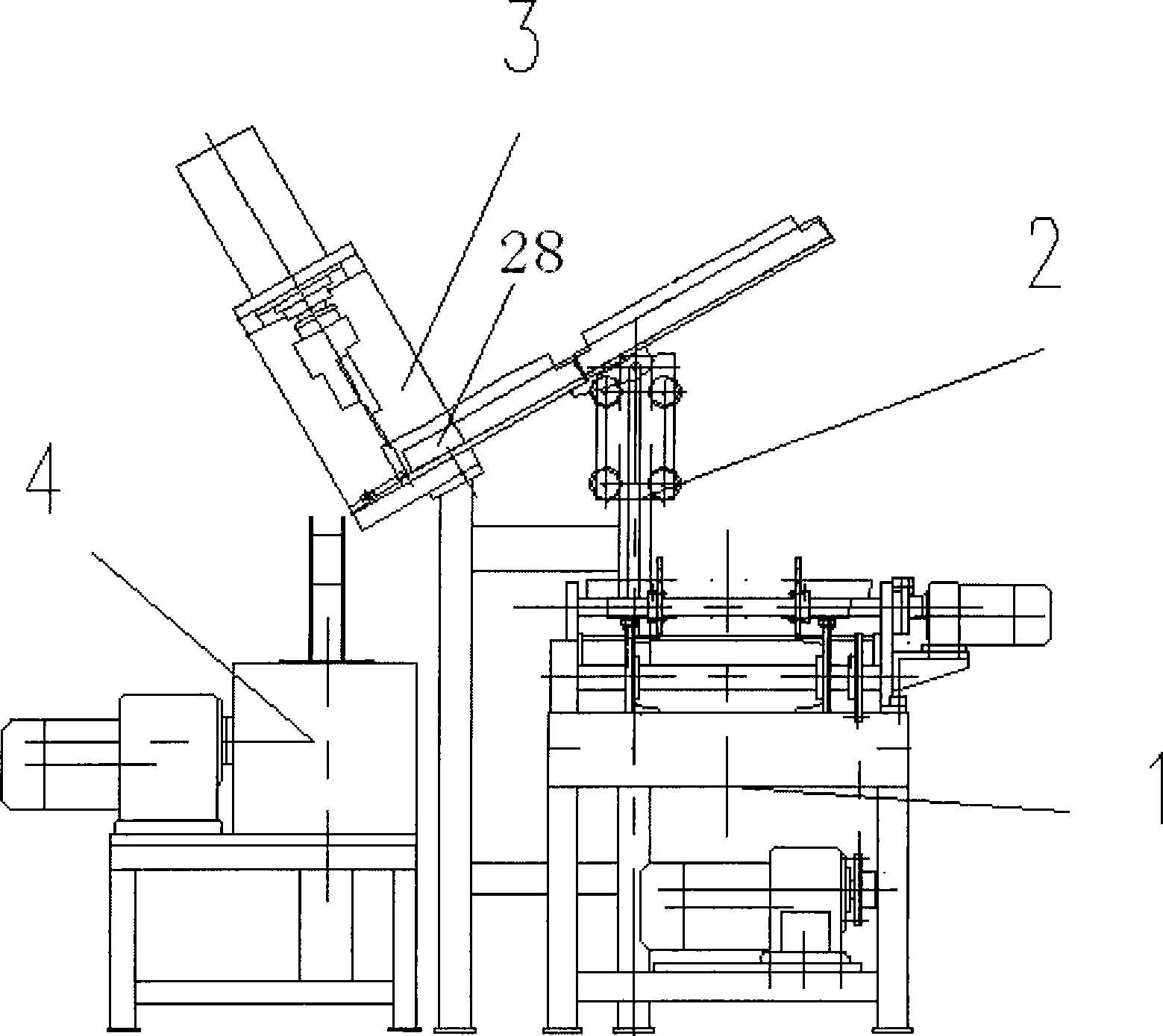

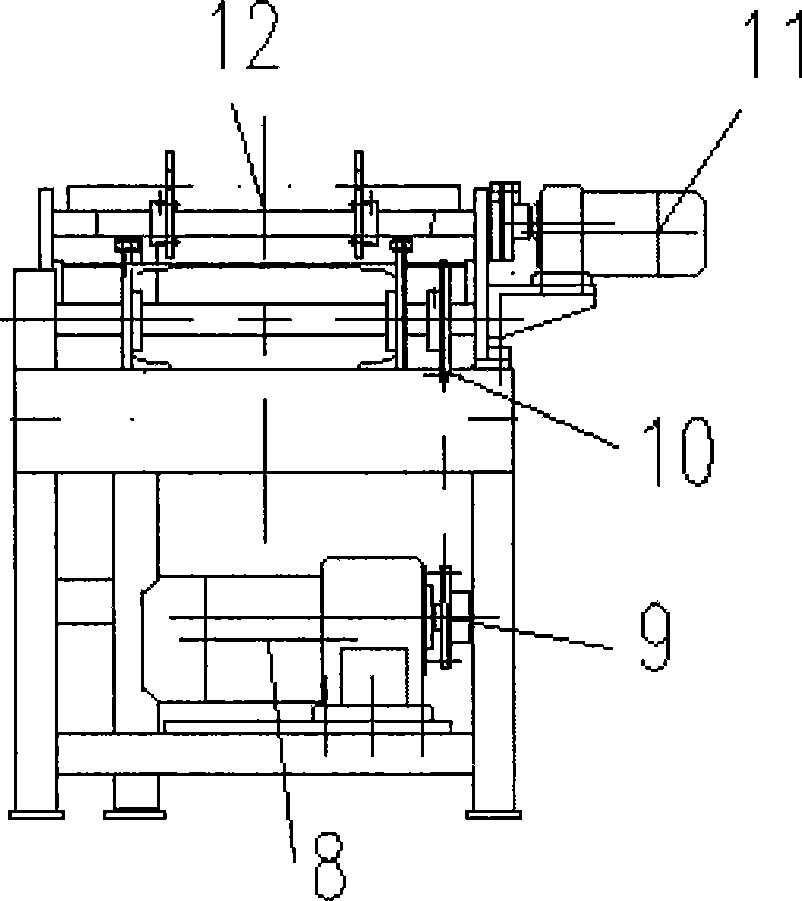

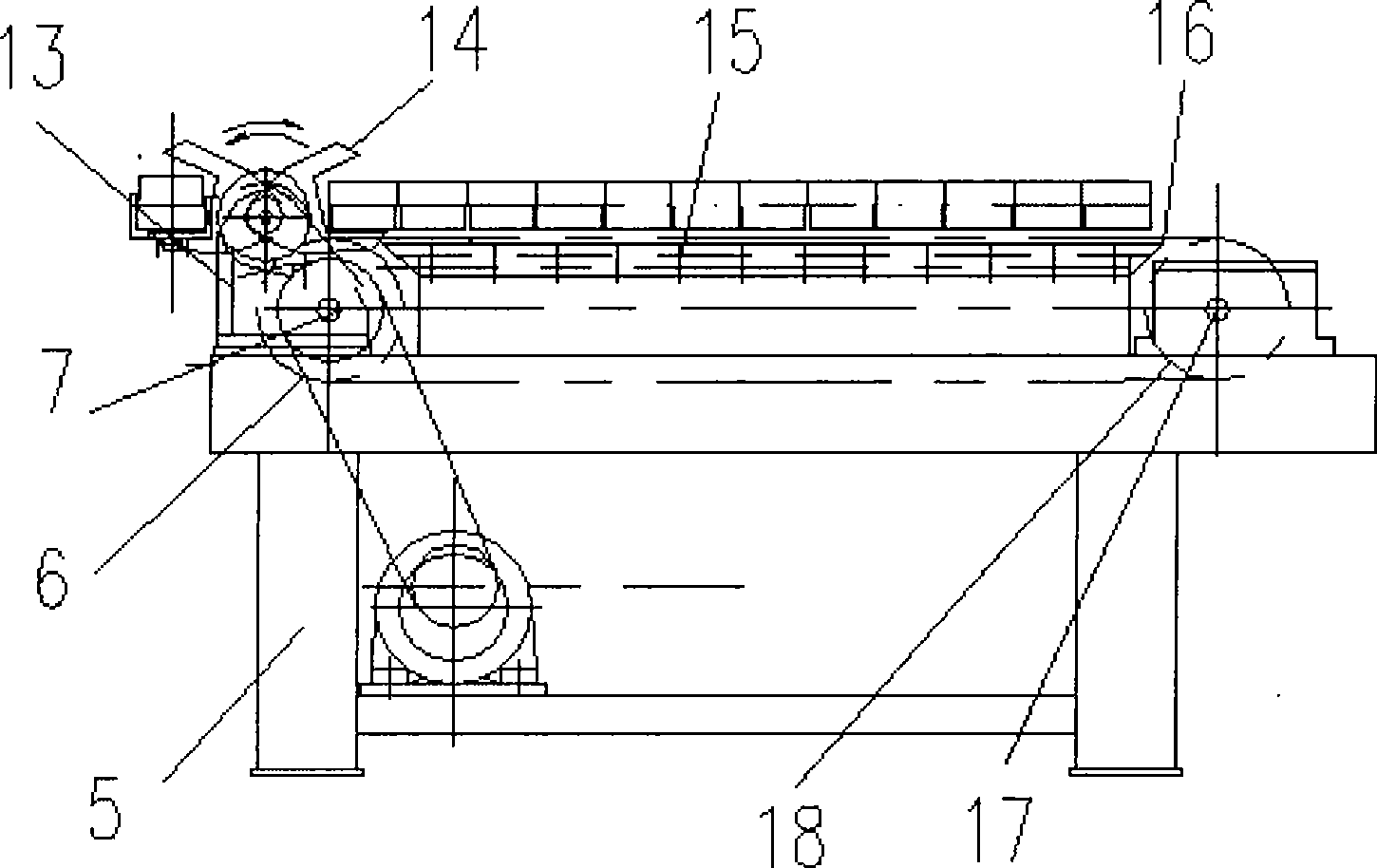

[0026] Example 1 as figure 1 As shown, this automatic production line for lead ingot granulation includes a control mechanism, a feeding mechanism, a lead ingot cake cutting mechanism 3, and a granulator 4. The lower anvil groove 28 of the cake mechanism 3 is docked, and the lower anvil groove 28 of the lead ingot cake cutting mechanism 3 is docked with the feed port of the granulator 4, so that the feed mechanism can send the lead ingot to the lower anvil of the lead ingot cake cutting mechanism 3 In the groove 28, the lead ingot cake cutting mechanism 3 cuts the lead ingot into the feed inlet of the lead cake and sends it to the pelletizer 4, and the pelletizer 4 cuts the lead cake into granular. The feeding mechanism includes a lead ingot storage and transportation mechanism 1 and a lead ingot lifting mechanism 2. The trough 22 of the lead ingot lifting mechanism 2 is fixed at the fork of the lead ingot storage and transportation mechanism 1 after the turning fork 14 is tur...

Embodiment 2

[0034] Embodiment 2 is basically the same as Embodiment 1, and the difference is that a power mechanism is fixed on the frame of its granulator 4, and the power mechanism is connected with the granulation mechanism through a transmission mechanism. The granulation mechanism includes a plurality of punches and The corresponding die. That is to say, its granulation process is stamped into granules by a plurality of round punch dies, and the punching press belongs to known punching presses.

[0035] In this embodiment, the lead ingot is sent into the lead ingot cake cutting device and the granulator through the drive of the reduction motor, the lifting cylinder and the inclination of the trough due to the self-weight slide of the chain and the turning fork, and the lead ingot is continuously and uninterrupted. Cut into lead cakes directly in the cold state, and then extruded into lead pellets from the lead cakes. Because the limiter in the feeding mechanism can control the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com