Hobbing type cross-cutting shear

A cross-cutting and rolling-cutting technology, applied in the field of sheet metal shearing machines, can solve problems such as reduced shearing efficiency, unfavorable equipment strength, and influence on adjustment accuracy, so as to reduce equipment cost and energy consumption, and reduce design workload , Improve the effect of adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

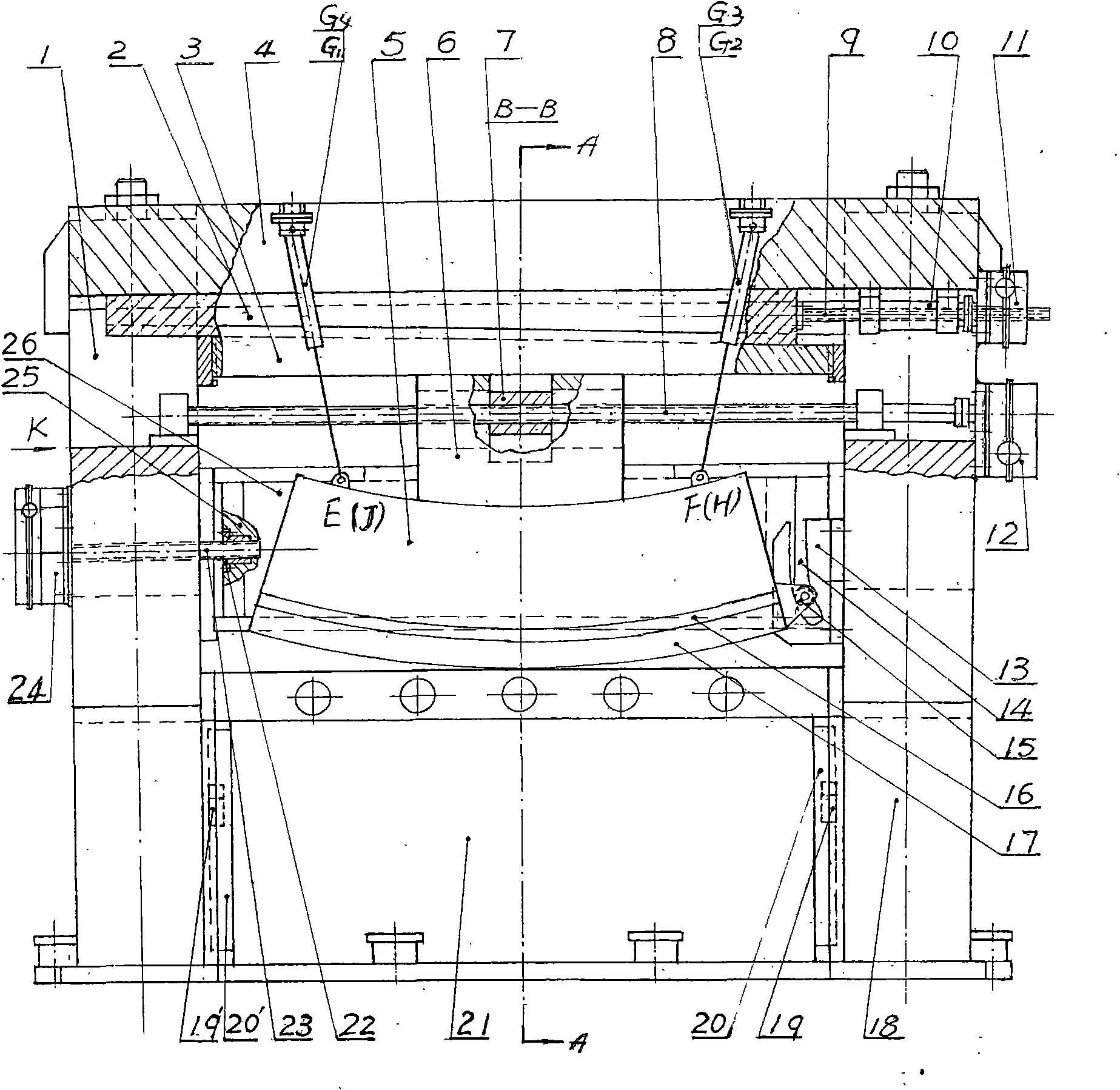

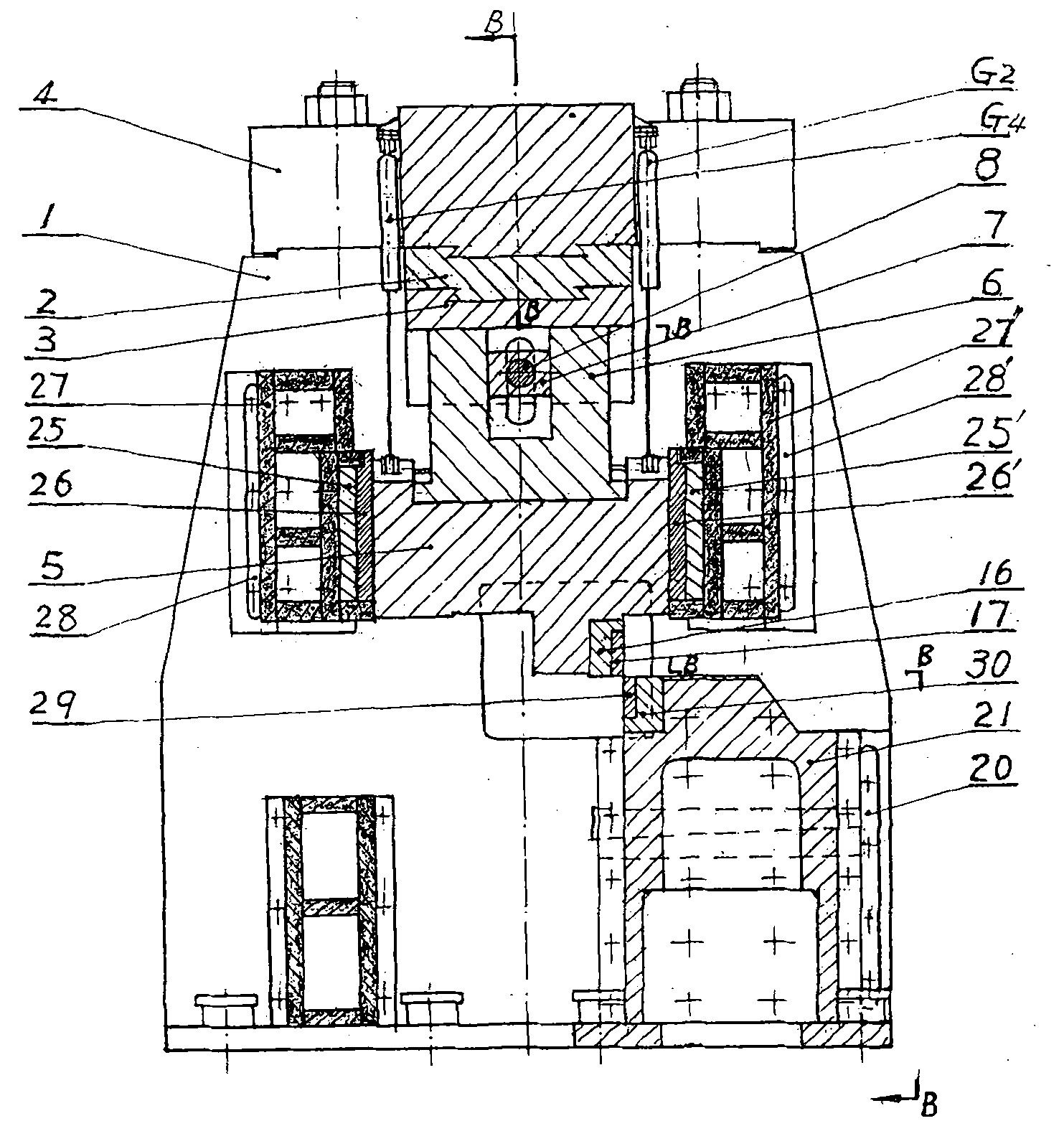

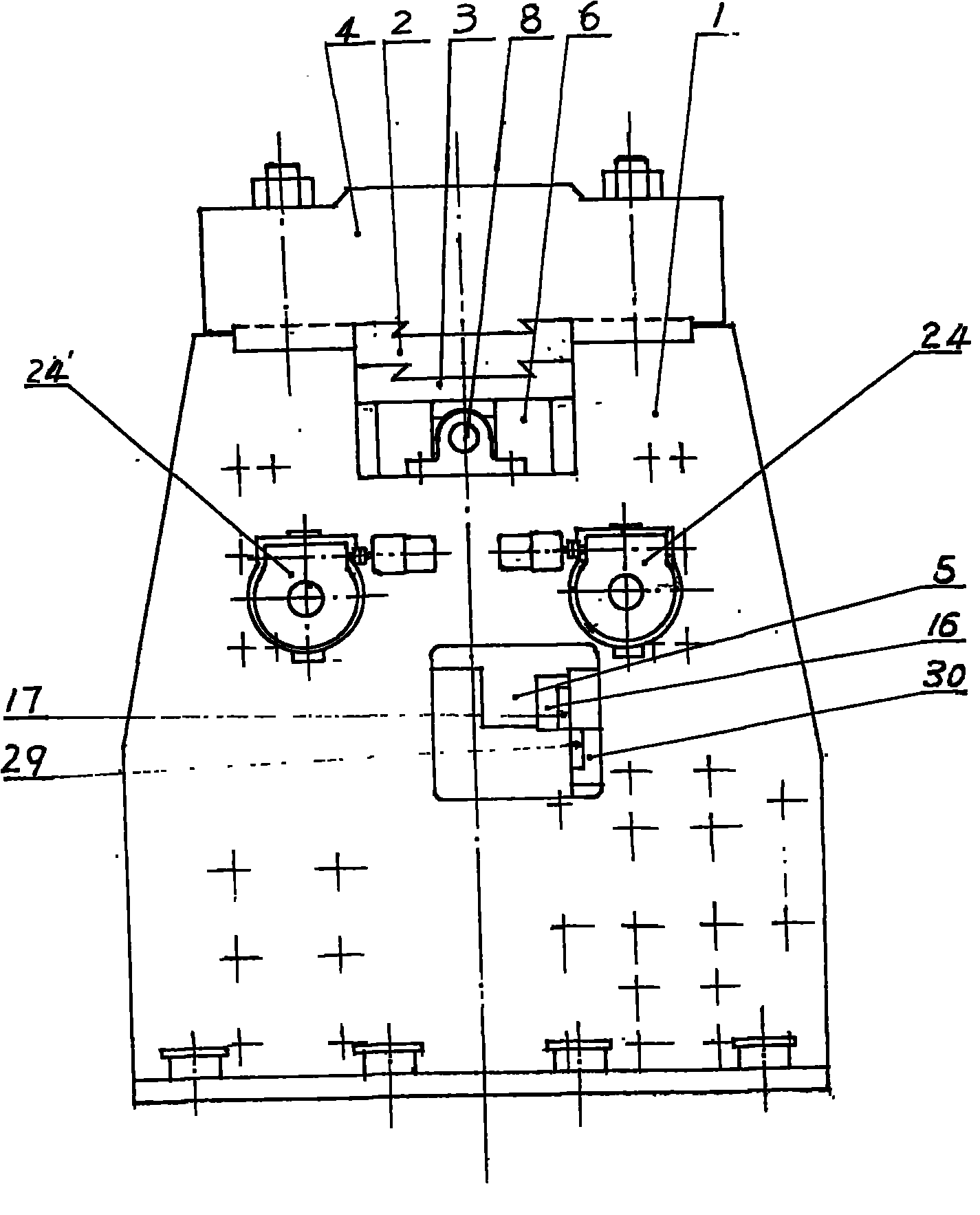

[0043] (1) The upper cutting edge is used for pure rolling shear: such as figure 1As shown, when the transmission box 12 drives the ball screw 8 to rotate, the ball nut 7 drives the arcuate sliding seat 6 to move left or right, and the arcuate sliding seat 6 forces the upper knife by contacting the arc surface of the upper knife rest 5 Frame 5 makes pure rolling shear under the restriction of roller 15 and guide groove 14 together with upper cutting edge 17 .

[0044] (2) The lifting adjustment of the upper cutting edge: such as figure 1 As shown, when the transmission box 11 drives the ball nut 10 to rotate, the matched ball screw 9 drives the upper wedge 2 to move horizontally, and through the contact of the two wedges with the inclined surface and the action of the balance hydraulic cylinder, the lower wedge 3 is forced to The arc slide seat 6, the upper knife rest 5 and the upper cutting edge 17 move upwards or downwards to realize the adjustment of the overlapping amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com