Drum shear

A technology of shearing machine, roller type, applied in the field of application of a method, to achieve the effect of reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

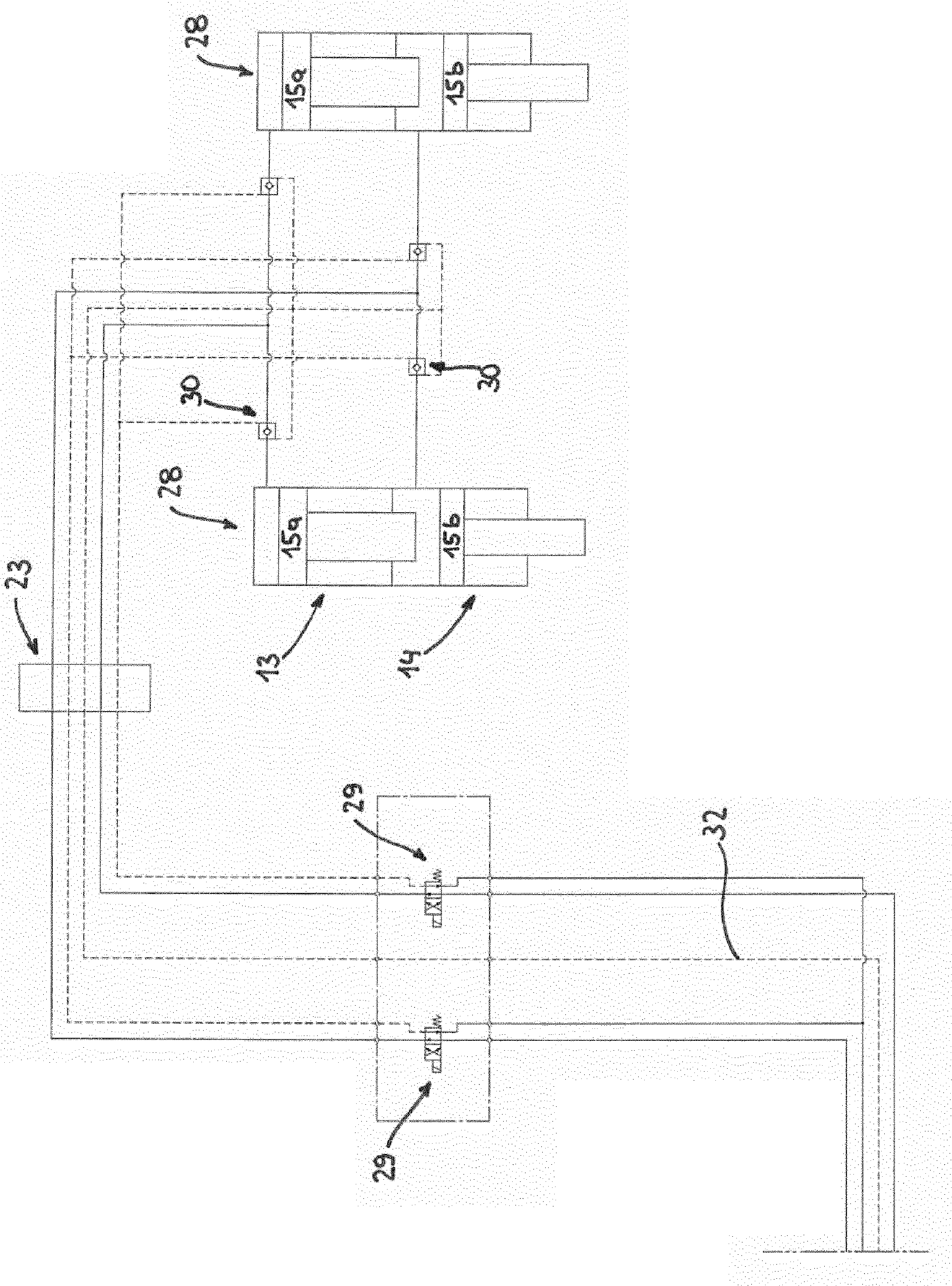

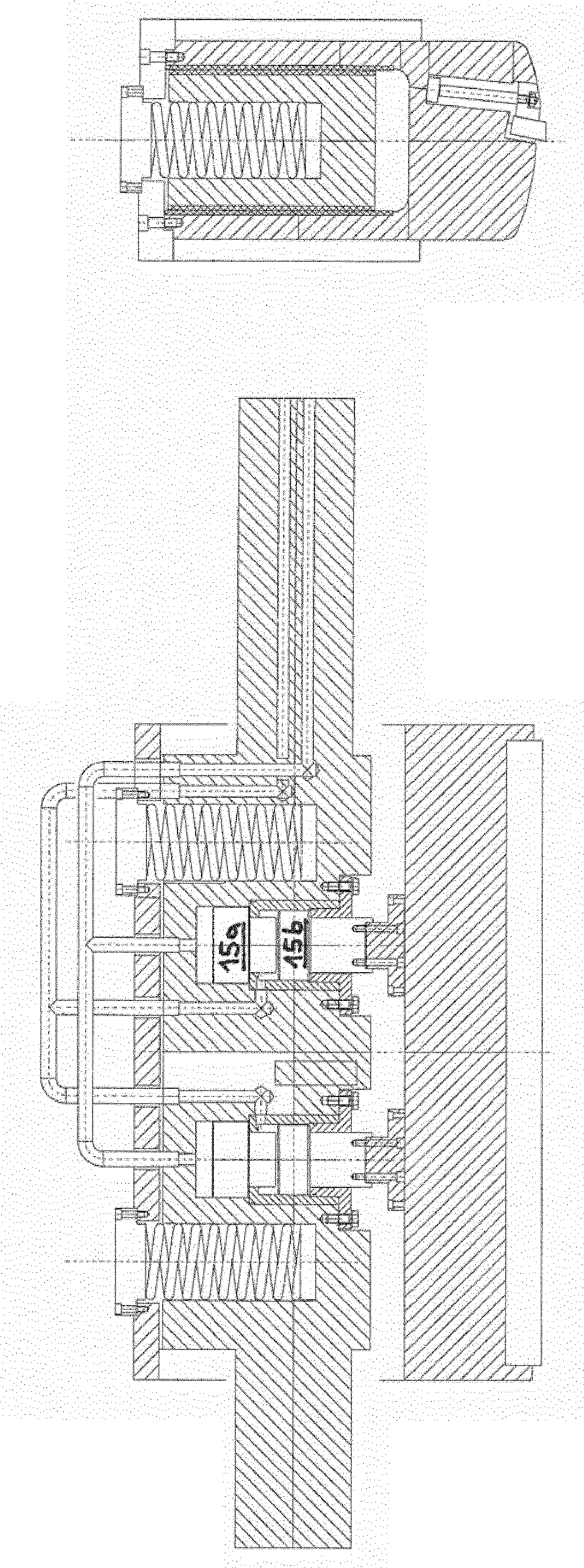

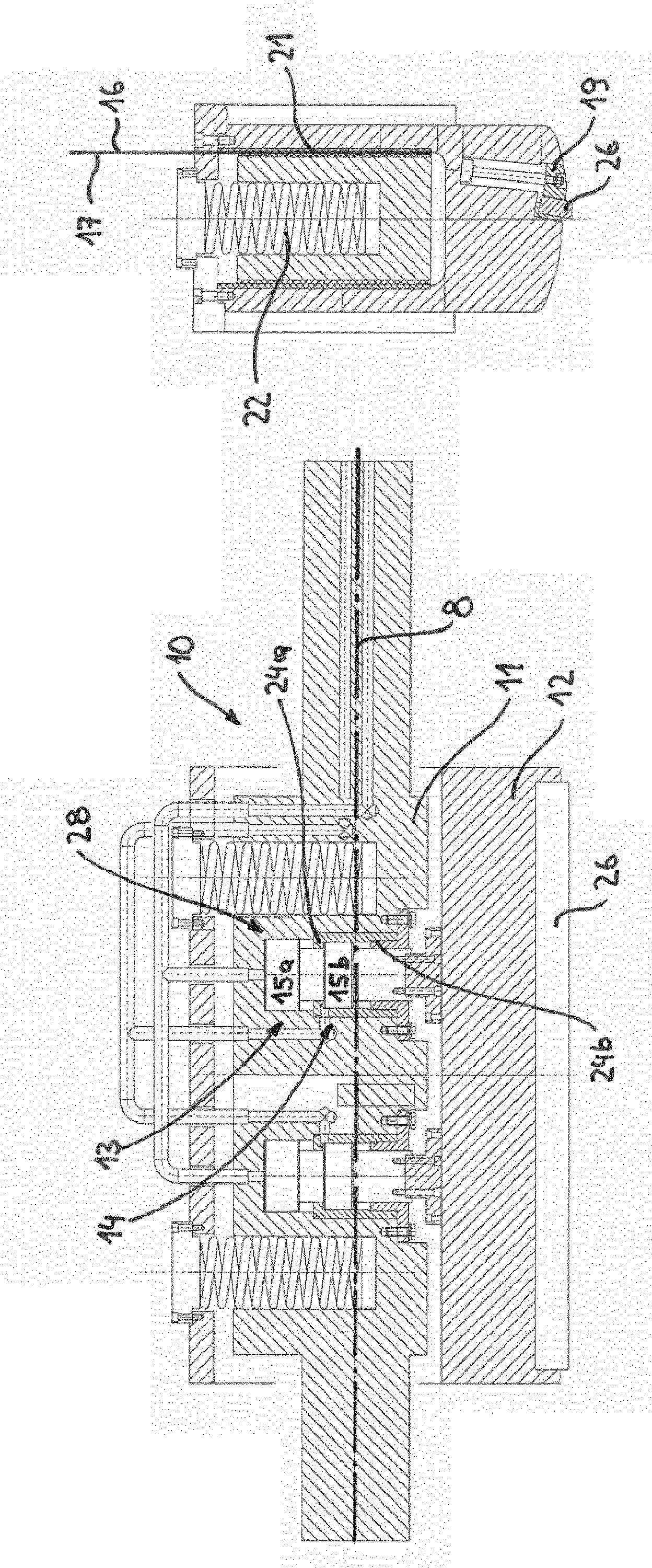

[0045] said figure 1 An exemplary embodiment of a drum shear 1 according to the invention is shown in front view. The drum shear 1 is used for transversely cutting a fast-moving thin steel strip 2 . To carry out the cut, a stroke of approximately 70 mm is performed. The double-drum shear 1 comprises an upper drum 10 and a lower drum 20 , the rotation axes 8 of which are rotatably supported in the frame 27 at a fixed distance from each other. The two cylinders 10 , 20 rotate in opposite directions with a knife 26 each. The rolling stock 2 to be sheared travels from the left to the drum shear 1 in the direction of the arrow 3, is separated at the desired moment, and is figure 1 in the schematic diagram left from the right. Typical speeds of the rolled strip 2 are 1 m / s to 20 m / s, or higher. The steel strip 2 generally has a thickness of approximately 0.5 mm to 5 mm. A knife play of no more than 30% of the strip thickness at the moment of cutting therefore requires very pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com