Precision forming method of ultrathin stainless steel substrate for flexible product, obtained substrate and application thereof

A technology of precision molding and stainless steel, applied in furnace types, manufacturing tools, metal rolling, etc., can solve the problems of insufficient performance, high efficiency, and low cost of flexible solar cells and flexible display systems, and achieve simple and easy production methods Line, high efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

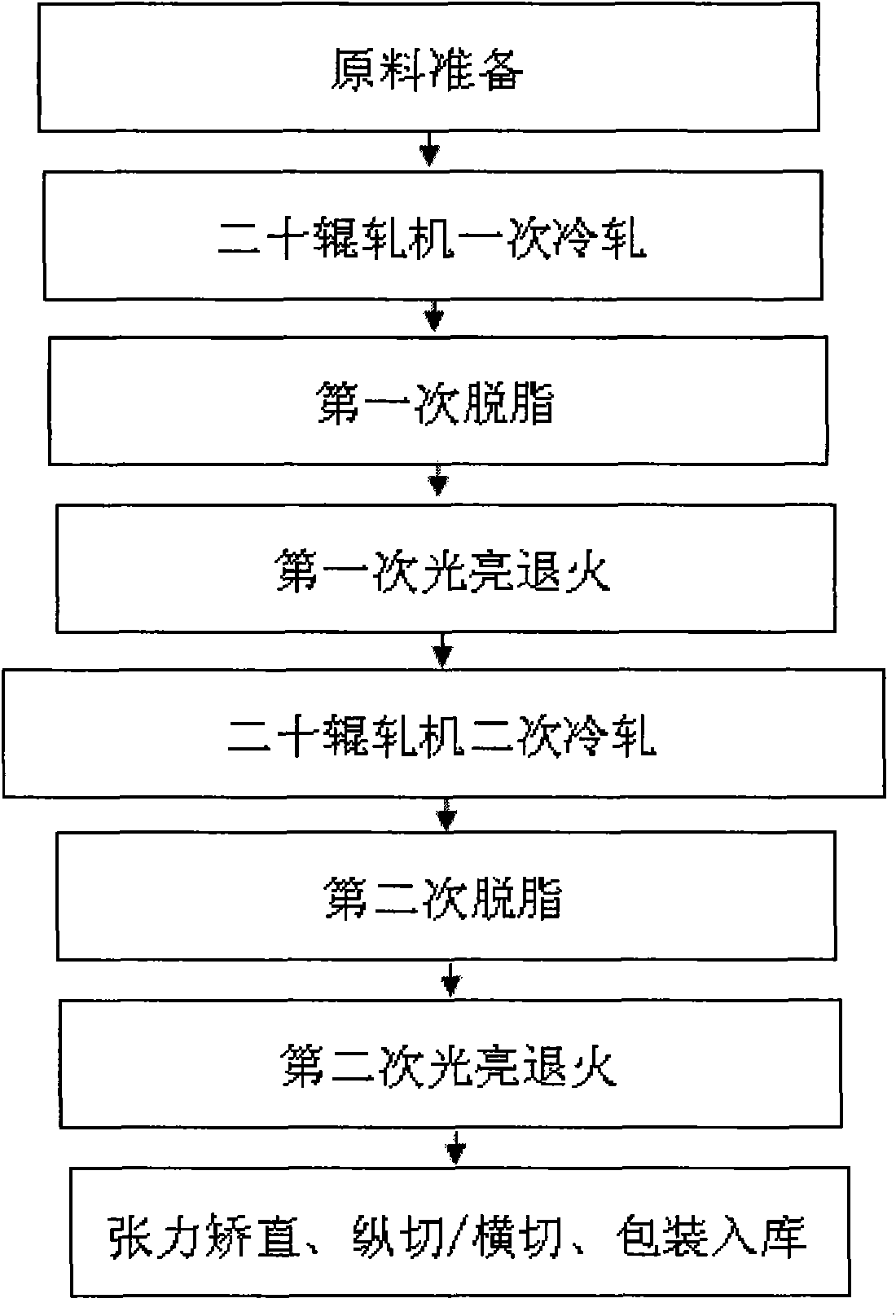

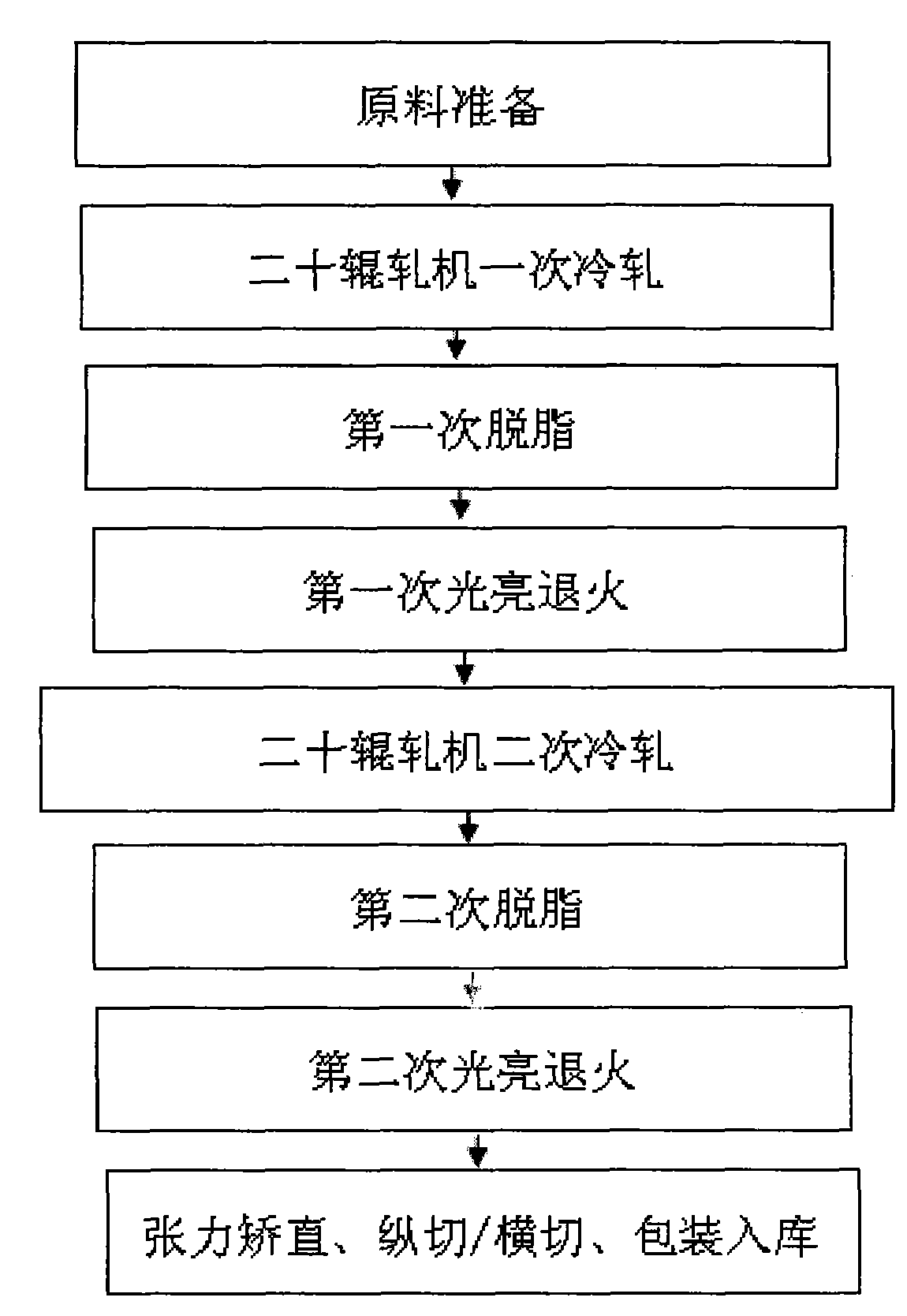

[0028] The cold-rolled 2B surface AISI304 stainless steel strip with a thickness of 0.8mm is used as the raw material, and it is cold-rolled by a 20-high rolling mill for the first time, degreased for the first time, bright annealed for the first time, cold-rolled twice by a 20-high rolling mill, and secondly. First degreasing, second bright annealing, tension straightening, slitting / cross-cutting, inspection, packaging and storage, etc., to obtain ultra-thin stainless steel base products for flexible products. Among them, the surface roughness of the work rolls in the secondary cold rolling of the 20-high rolling mill is Ra0.50μm, and the pass deformation rate is 40%. The first bright annealing temperature is 1080 ° C, the holding time is 15 minutes, the reducing atmosphere is protected, and the cooling is rapid; The temperature of the second bright annealing is 1060° C., the holding time is 10 minutes, the reducing atmosphere is protected, and the cooling is rapid. The prepa...

Embodiment 2

[0031] The cold-rolled 2B surface AISI316 stainless steel strip with a thickness of 1mm is used as the raw material, and it is cold-rolled by a 20-roll mill for the first time, degreased for the first time, bright annealed for the first time, cold-rolled for the second time by a 20-roll mill, and the second time Degreasing, second bright annealing, tension straightening, slitting / cross-cutting, inspection, packaging and warehousing, etc., to obtain ultra-thin stainless steel base products for flexible products. Among them, the surface roughness of the work rolls in the secondary cold rolling of the 20-high rolling mill is Ra0.10μm, and the pass deformation rate is 70%; the first bright annealing temperature is 1050 ° C, the holding time is 25 minutes, the reducing atmosphere is protected, and the cooling is rapid; The temperature of the second bright annealing is 1040° C., the holding time is 9 minutes, the reducing atmosphere is protected, and the cooling is rapid. The prepar...

Embodiment 3

[0034] The cold-rolled 2B surface AISI301 stainless steel strip with a thickness of 0.8mm is used as raw material, and it is cold-rolled by a 20-high rolling mill, degreased for the first time, bright annealed for the first time, cold-rolled twice by a 20-high rolling mill, and secondly First degreasing, second bright annealing, tension straightening, slitting / cross-cutting, inspection, packaging and storage, etc., to obtain ultra-thin stainless steel base products for flexible products. Among them, the surface roughness of the work rolls in the secondary cold rolling of the 20-high rolling mill is controlled at Ra0.02μm, and the pass deformation rate is 65%; the first bright annealing temperature is 1070 ° C, the holding time is 15 minutes, the reducing atmosphere is protected, and the cooling is rapid ; The second bright annealing temperature is 1060 ° C, the holding time is 10 minutes, the reducing atmosphere is protected, and the cooling is rapid. The prepared ultra-thin s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com