Stalk cutter

A straw shredder and frame technology, which is applied to cutting equipment, agricultural machinery and implements, grain processing, etc., can solve the problems of not being able to reach power plants, low crushing efficiency, and large frictional resistance, so as to reduce power consumption, Reduced layout density and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

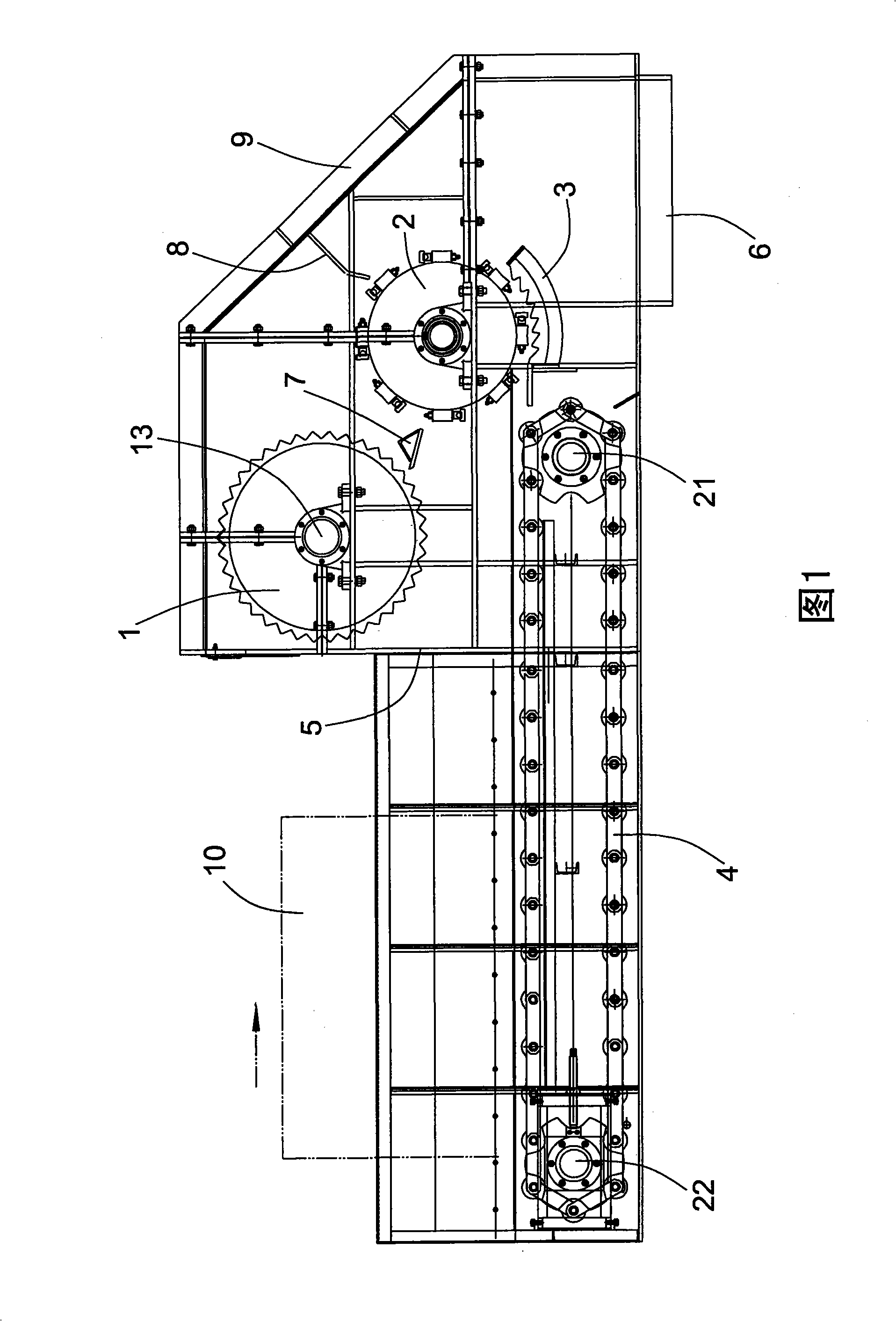

[0027] 1 cloth drum 2 cutting drum 3 crushed sieve

[0028] 4 chain scale plate conveyor 5 feed port 6 discharge port

[0029] 7 Binder 8 Deflector 9 Rack

[0030] 10 straw bales

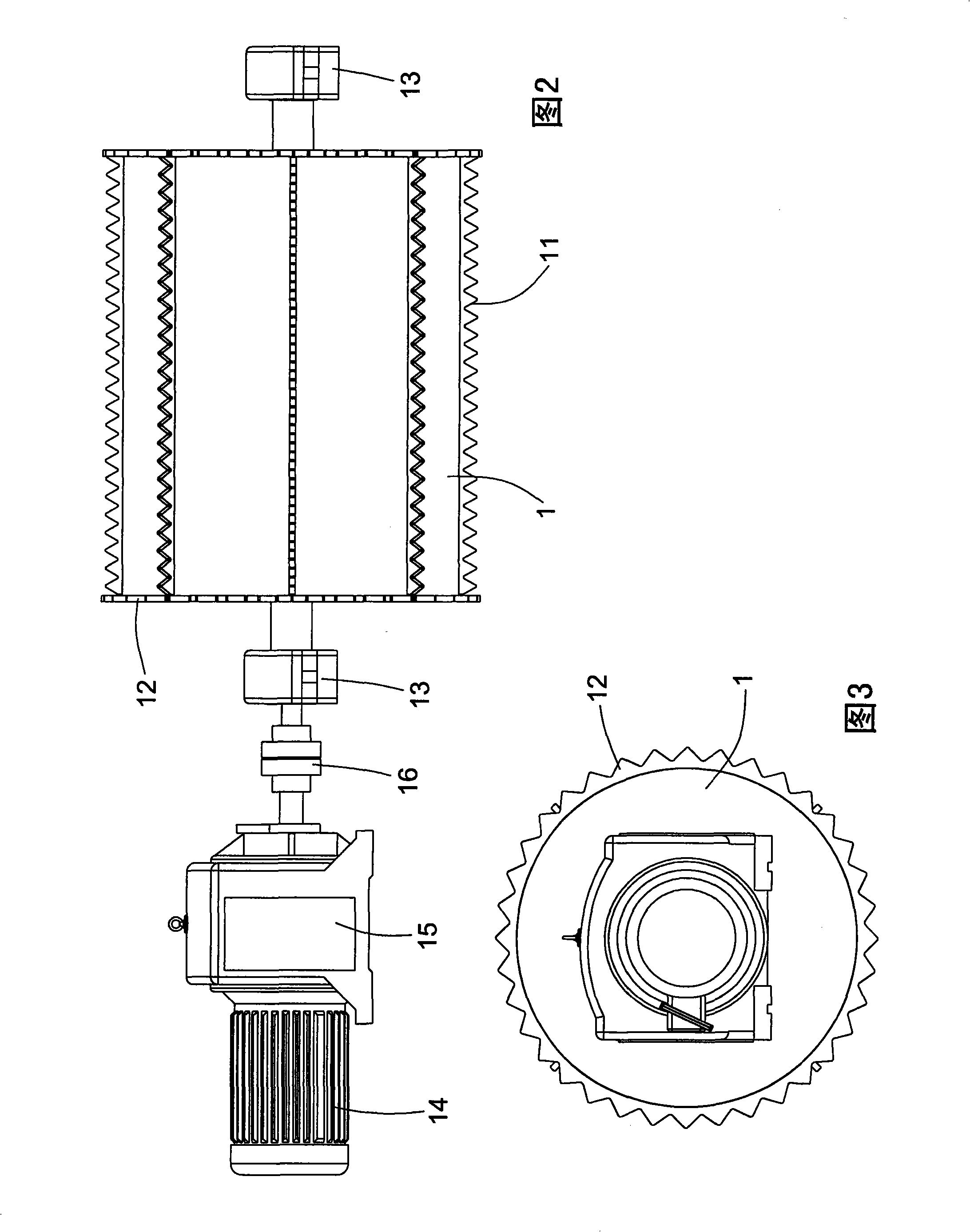

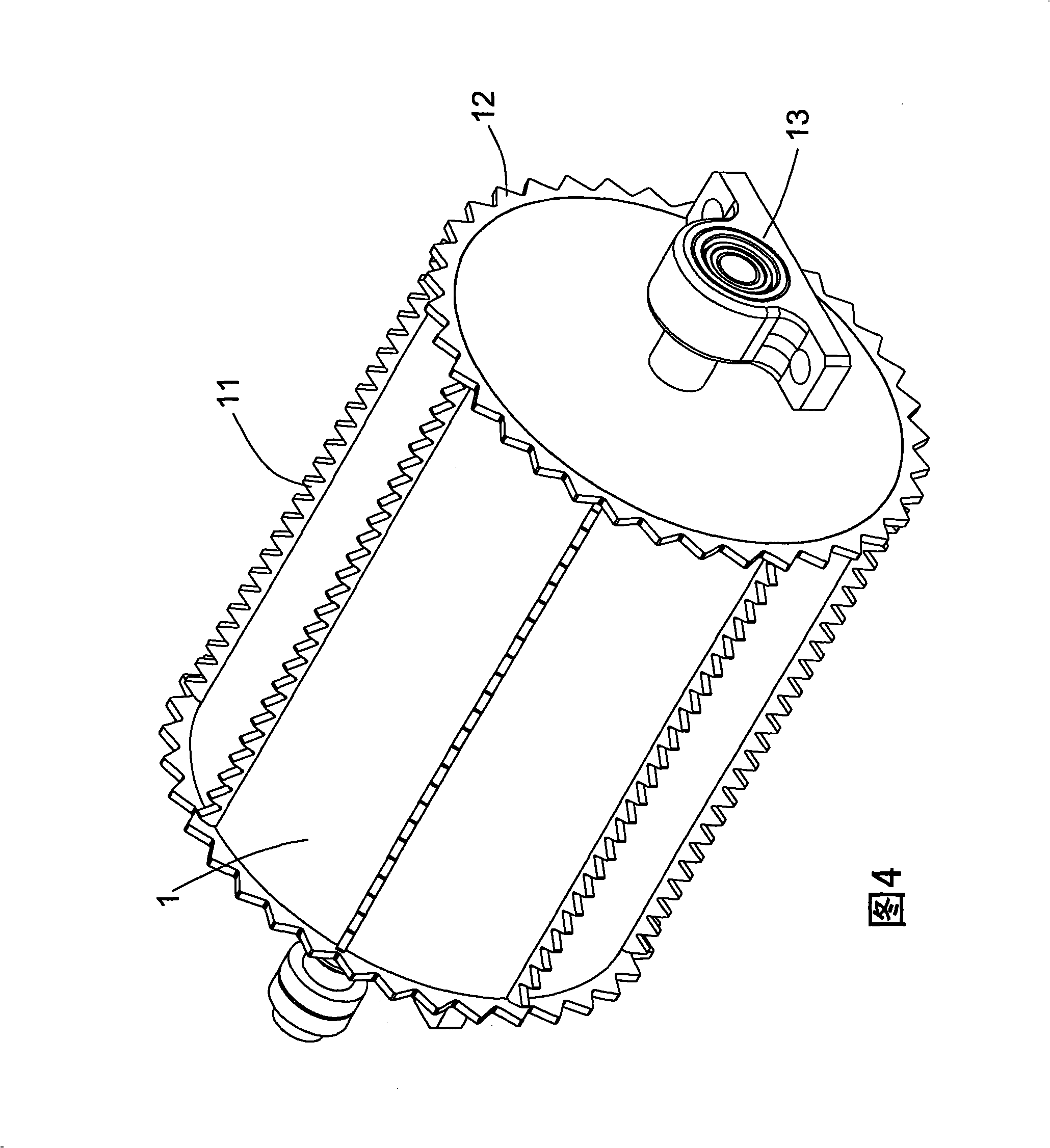

[0031] 11 Transverse cutting teeth 12 Circumferential cutting teeth 13 Bearing seat

[0032] 14 Motor 15 Reducer 16 Coupling

[0033] 17 knife seat 18 knife handle 19 knife head

[0034] 20 chopping knife 21 roller 22 roller 23 bearing seat

[0035] 24 Motor 25 Reducer 26 Coupling

[0036] 27 frame 28 sieve 29 blade teeth 30 clearance

[0037] 31 Tapered through hole 32 Nut 33 Smooth shaft head 34 Tail

[0038] Please refer to Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the present invention is a kind of straw shredder, comprising a cloth drum 1, a material cutting drum 2, a frame 9, a chain-type scale plate conveyor 4, and the structure of the frame 9 The front face is provided with a material inlet 5, and the bottom surface of the rear end of the frame is provided with a material outlet 6.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com