Rubber sheet granule cutter

A technology of granulator and film, which is applied in the direction of metal processing, etc., can solve the problems of difficult guarantee, high power consumption, easy bonding, etc., and achieve the effect of improving the efficiency and quality of rubber mixing, reducing labor intensity, and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

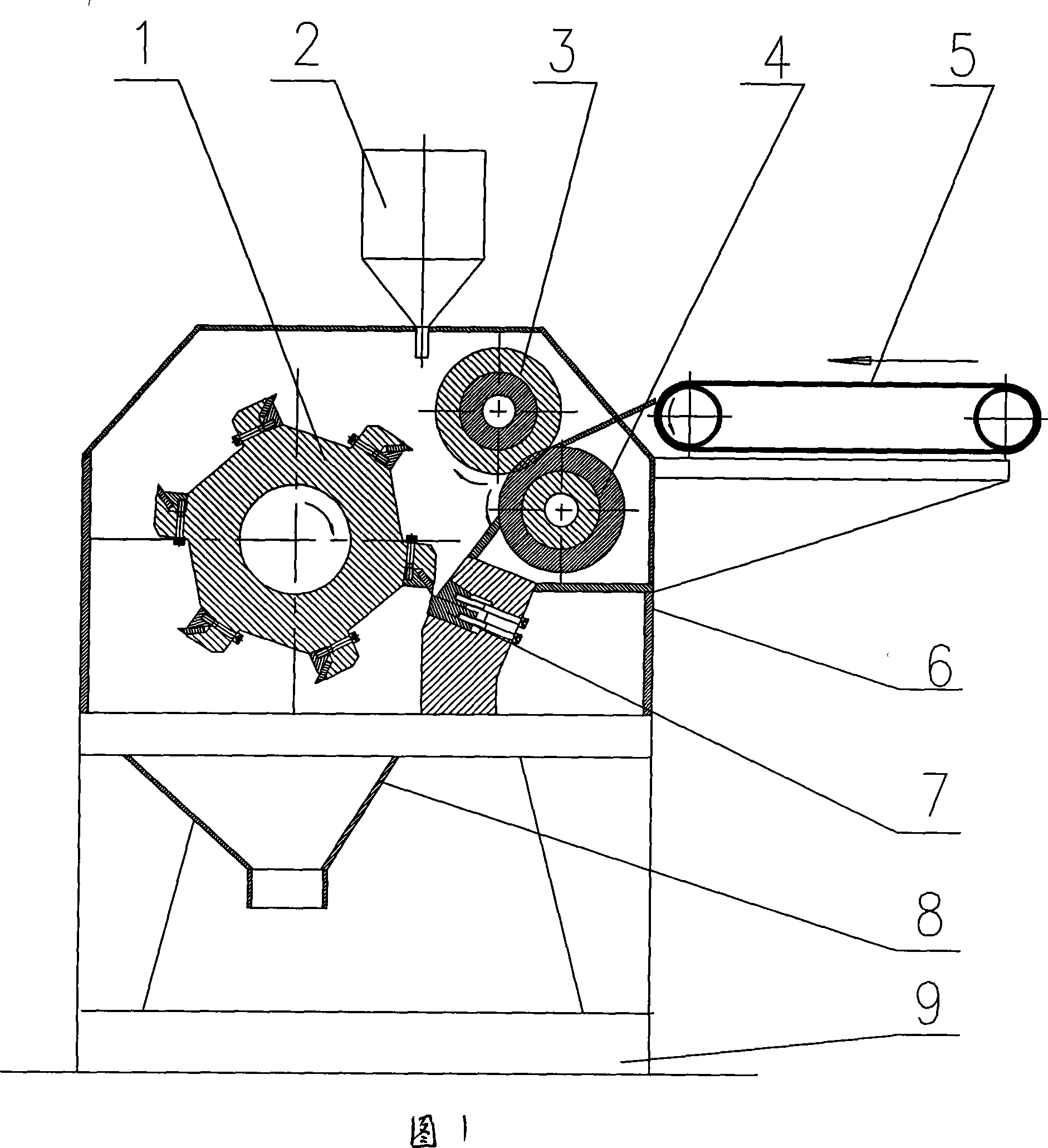

[0014] In Fig. 1, including film adding device 5, frame 6, machine base 9, the transmission belt end of film adding device 5 is provided with slitting device, and slitting device is two rows of disc type slitting lower knives 4 and slitting The upper cutting knife 3, the rotating shaft of the disc-type lower slitting knife 4 and the upper slitting knife 3 are perpendicular to the moving direction of the transmission belt, the lower slitting knife 4 and the corresponding end surface of the upper slitting knife 3 are close to each other, and the lower slitting knife 4 and slitting upper knife 3 rear parts, fixed cross-cutting fixed knife 7 and rotating cross-cutting hob 1 are installed, cross-cutting fixed knife 7 is a strip cutter, and cross-cutting hob 1 is on the rotating roll Inlaid with blades, the blade and the roller have a rising angle in the tangential direction, the upper slitting knife 3 and the lower slitting knife 4 are equipped with a pressing device in the axial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com