On-line transverse cutting machine for polystyrene plastic extruding cystosepiment

A polystyrene and foam board technology, applied in metal processing and other directions, can solve the problems of low work efficiency and waste of manpower for secondary cutting boards, and achieve the effects of saving manpower, compact structure and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

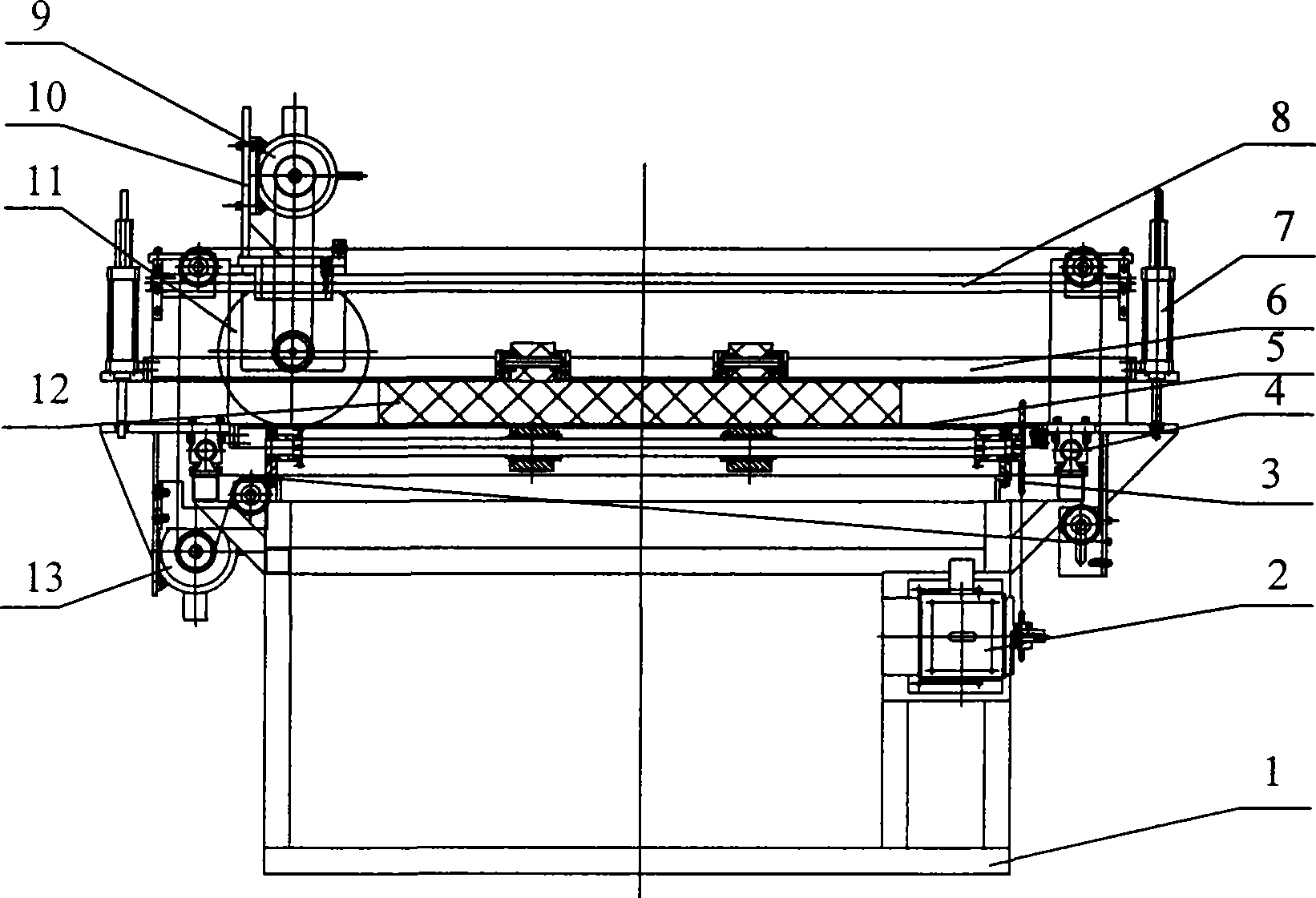

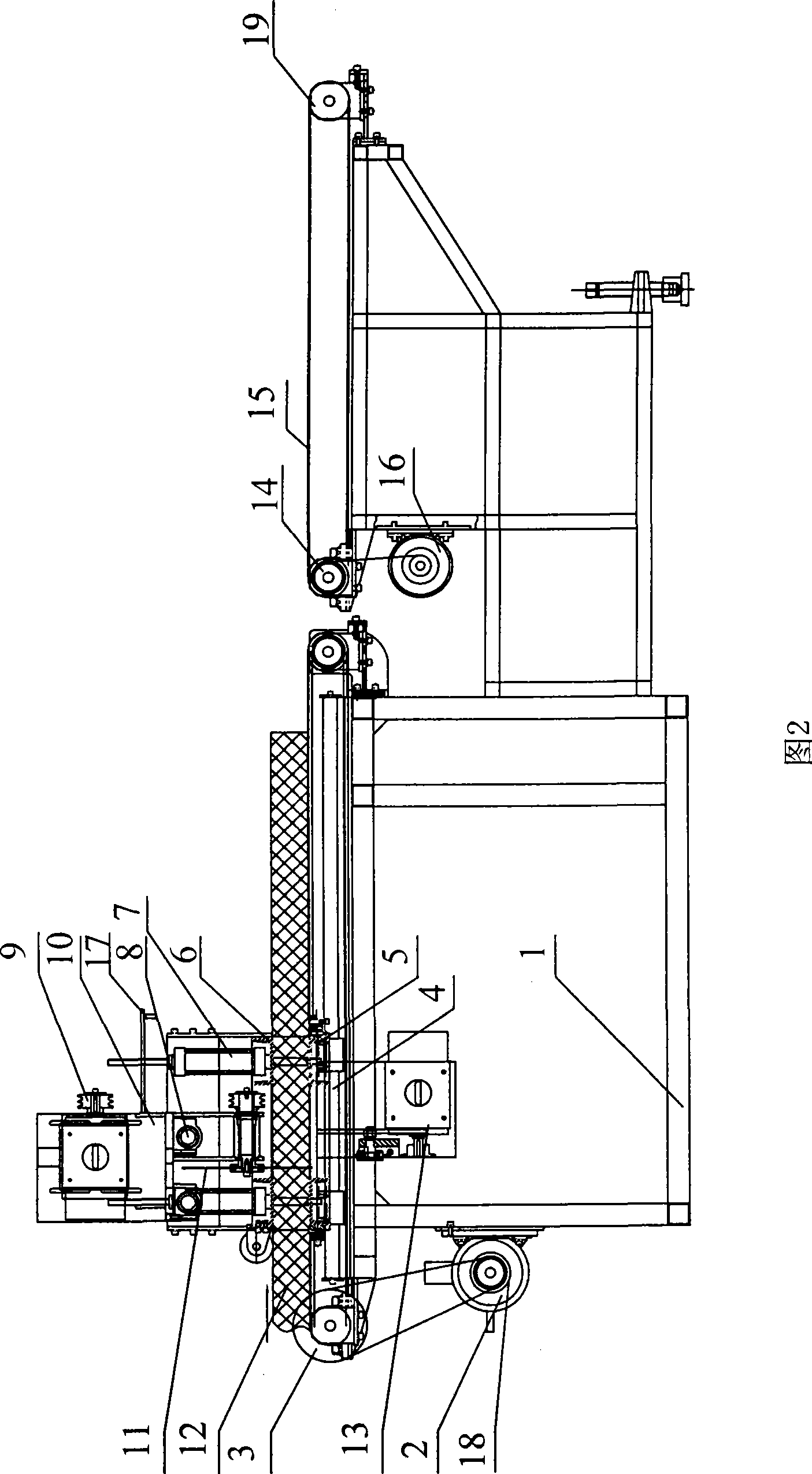

[0012] Refer to the attached figure 1 ~2, the polystyrene extruded foam board online cross-cutting machine of the present invention includes a frame 1, a horizontal moving mechanism, a cross-cutting mechanism, a plate conveying mechanism and a control mechanism. The upper part of the frame 1 is provided with two horizontal guide rails 4, and the horizontal guide rail 4 is equipped with a horizontal moving mechanism. The motor I 2 that the moving mechanism moves, the motor I 2 is installed on the lower part of one side of the frame 1, the output shaft of the motor I 2 is equipped with a driving sprocket 18, the driven sprocket 3 is installed on the frame 1, and the driven sprocket 3 Driven by a chain with the driving sprocket 18, the lower support plate 5 is installed on the horizontal guide rail 4 through a guide sleeve, and the lower support plate 5 and the upper pressure plate 6 are connected by an air cylinder 7, which controls the upper pressure plate 6 to move up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com