Amorphous-silicon-steel composite stator core for radial magnetic field motor and manufacturing method thereof

A composite stator and radial magnetic field technology, used in the manufacture of motor generators, stator/rotor bodies, magnetic circuits, etc., can solve the problem of non-uniform axial distribution of silicon steel core and amorphous iron core, and soft magnetic properties of iron core. Incompatibility with the electromagnetic scheme of the motor, inability to take advantage of the energy-saving advantages of amorphous materials, etc., to achieve the effects of easy industrialization, high saturation magnetic induction intensity, and simple manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

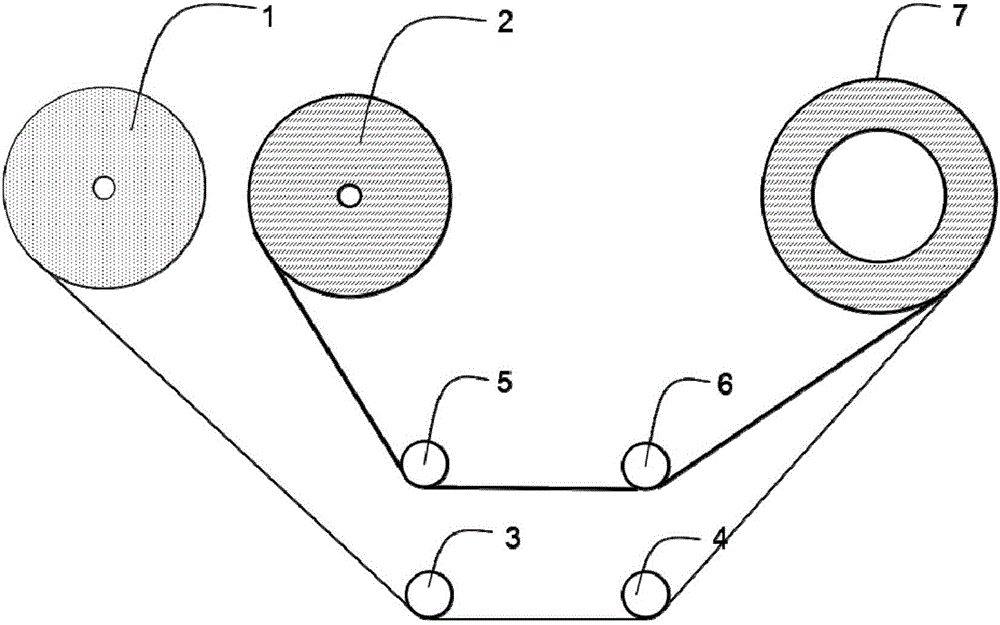

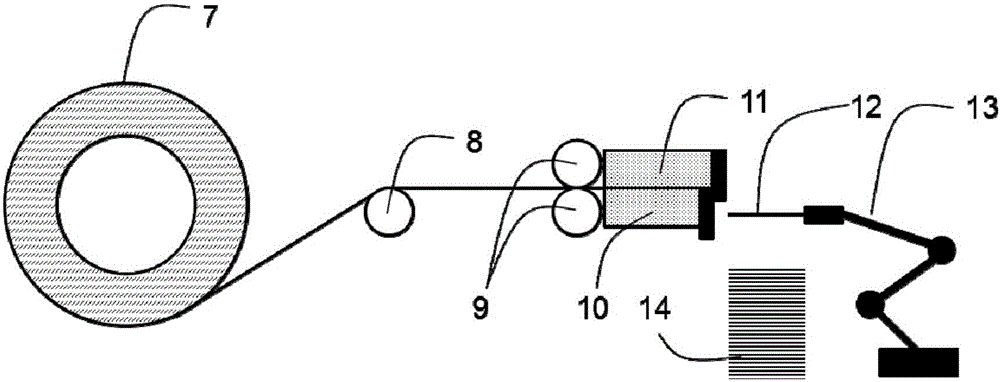

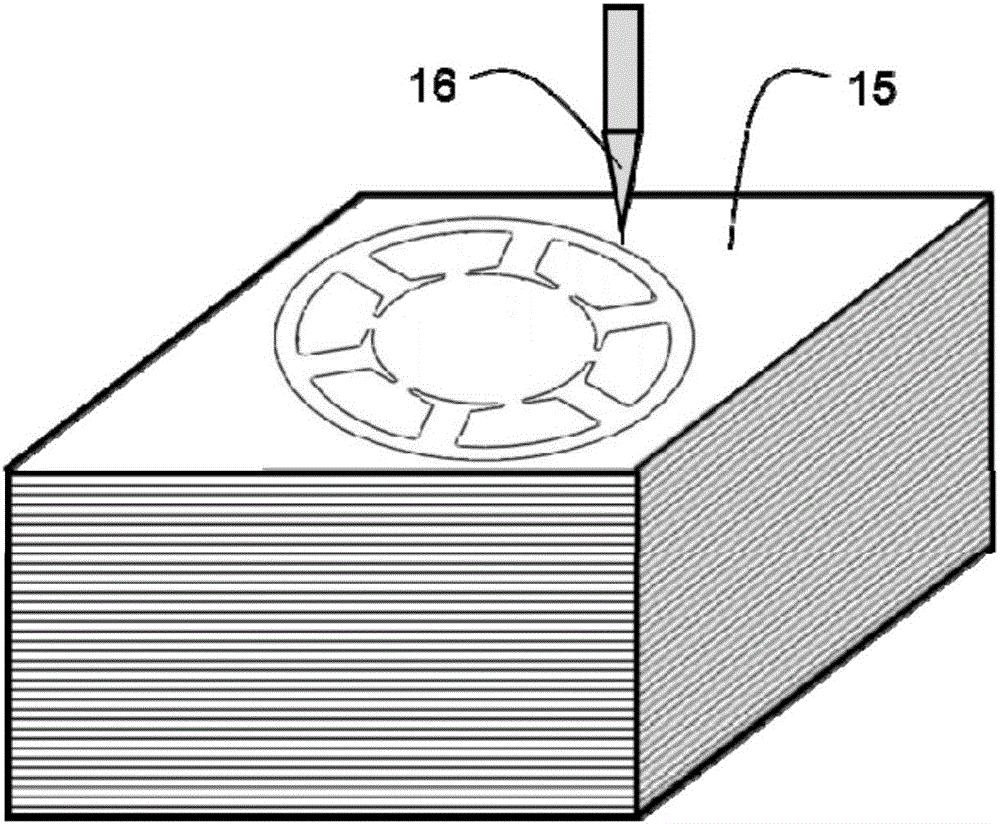

[0059] In this embodiment, the method for making the amorphous-silicon steel composite iron core for radial field motors using the method of the present invention is the same, only need to use different composition systems or different grades of amorphous or nanocrystalline thin strip materials Different amorphous-silicon steel composite stator cores can be prepared by replacing and selecting different process parameters according to the properties of different amorphous or nanocrystalline thin strip materials. Therefore, in the following, the stator core of a radial magnetic field motor is prepared by compounding non-oriented silicon steel with the grade of B35AV1900 and the amorphous strip with the grade of 1k101 as an example, and the specific implementation of the present invention will be further described in detail in conjunction with the accompanying drawings and examples. .

[0060] In this embodiment, the silicon steel strip grade B35AV1900, thickness 0.35mm, and band...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com