GaAs-based LED chip cutting method

A technology of LED chips and cutting methods, which is applied to fine working devices, electrical components, circuits, etc., can solve problems such as chip chipping and cracked tube cores, and achieve the effect of improving the appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

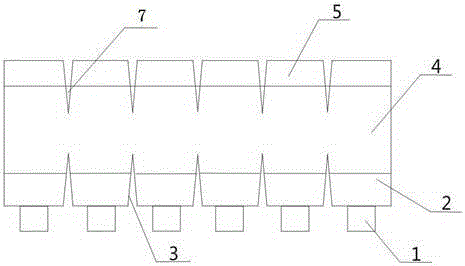

[0031] The cutting method of the GaAs-based LED chip of the present invention specifically comprises the following steps:

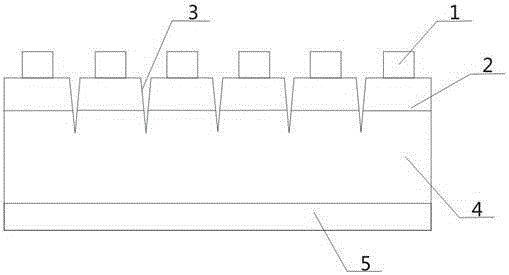

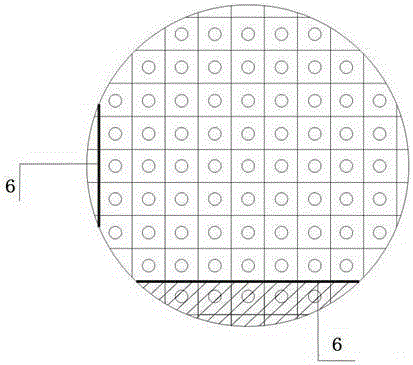

[0032] (1) Full half-cut on the P side

[0033] Place the electrode 1 of the P side of the LED chip upwards on the workbench of the saw blade, select the half-cut operation program and click "automatic cutting", the saw blade machine will automatically calibrate the level and start cutting until the CH1 and CH2 sides of the chip are cut. Such as figure 1 shown. Full half-cutting is first performed along the direction perpendicular to the large cleavage side of the chip, and then full-scale half-cutting is performed along the direction parallel to the large cleavage side to form criss-cross cutting grooves to separate the P-side electrodes 1 of the chip at equal intervals.

[0034] The initial feed speed of cutting is 10mm / s. After cutting 25 knives, the knife speed can be adjusted to 20-70mm / s according to the cutting conditions. 550-600μm. The half-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com