Method for removing residual stress of hot-rolling high-strength steel

A technology of residual stress and high-strength steel, which is applied in the field of steel processing, can solve the problems of difficult steel leveling tasks, large investment amount and high investment cost of bell annealing furnace, and achieves improved plate shape quality, good plate shape stability, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

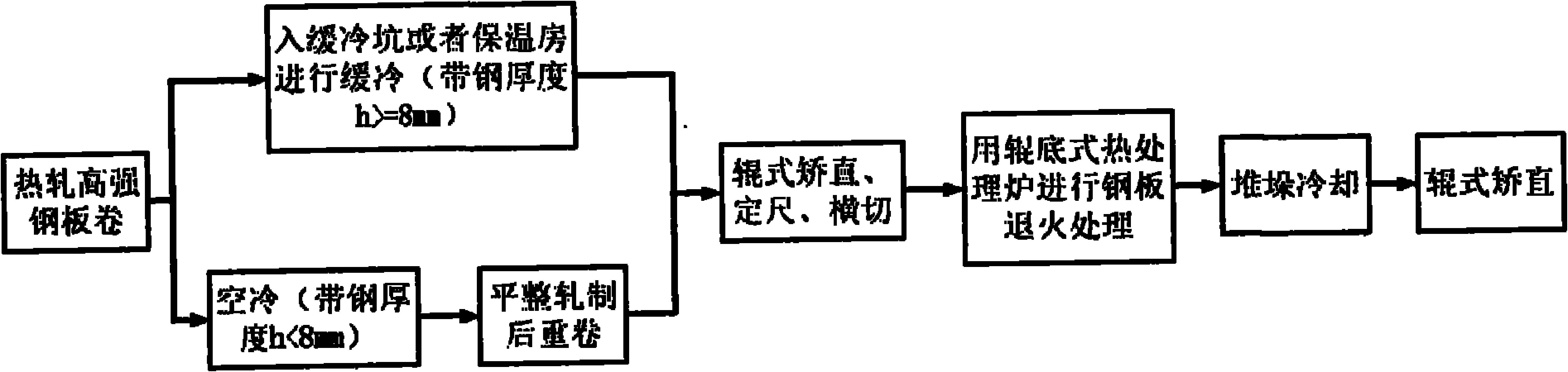

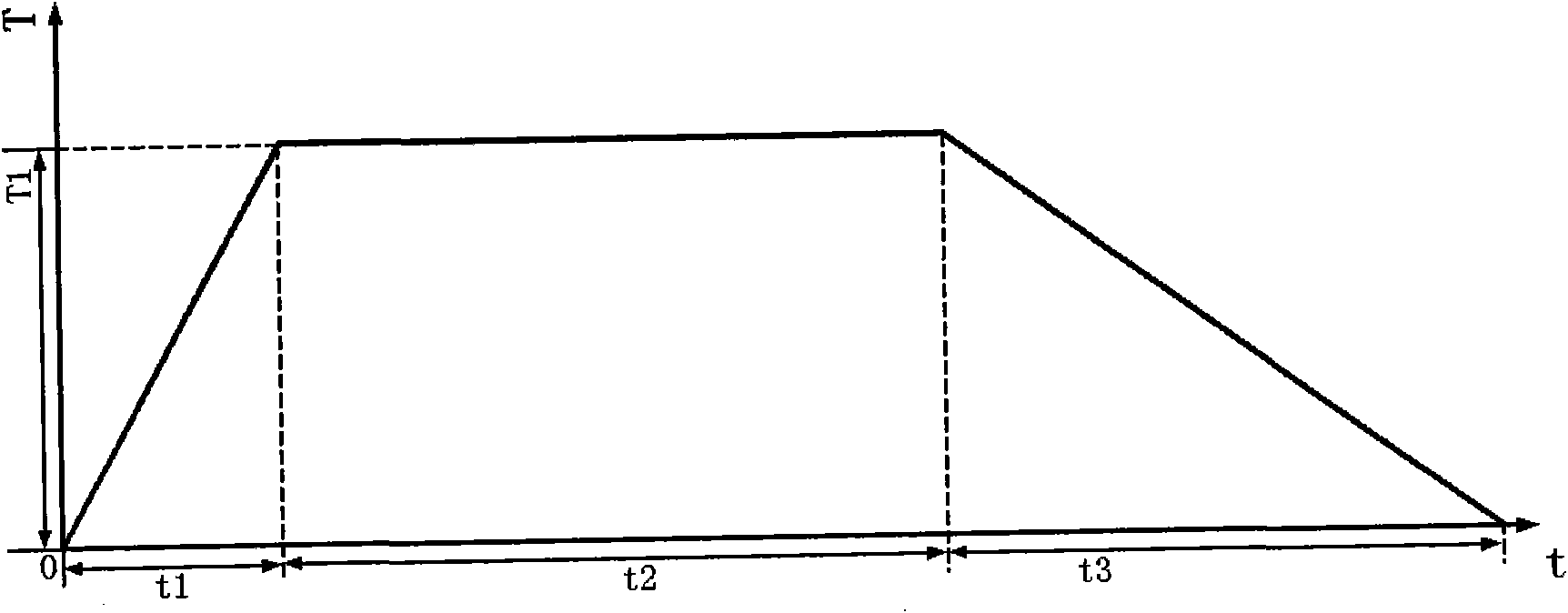

Method used

Image

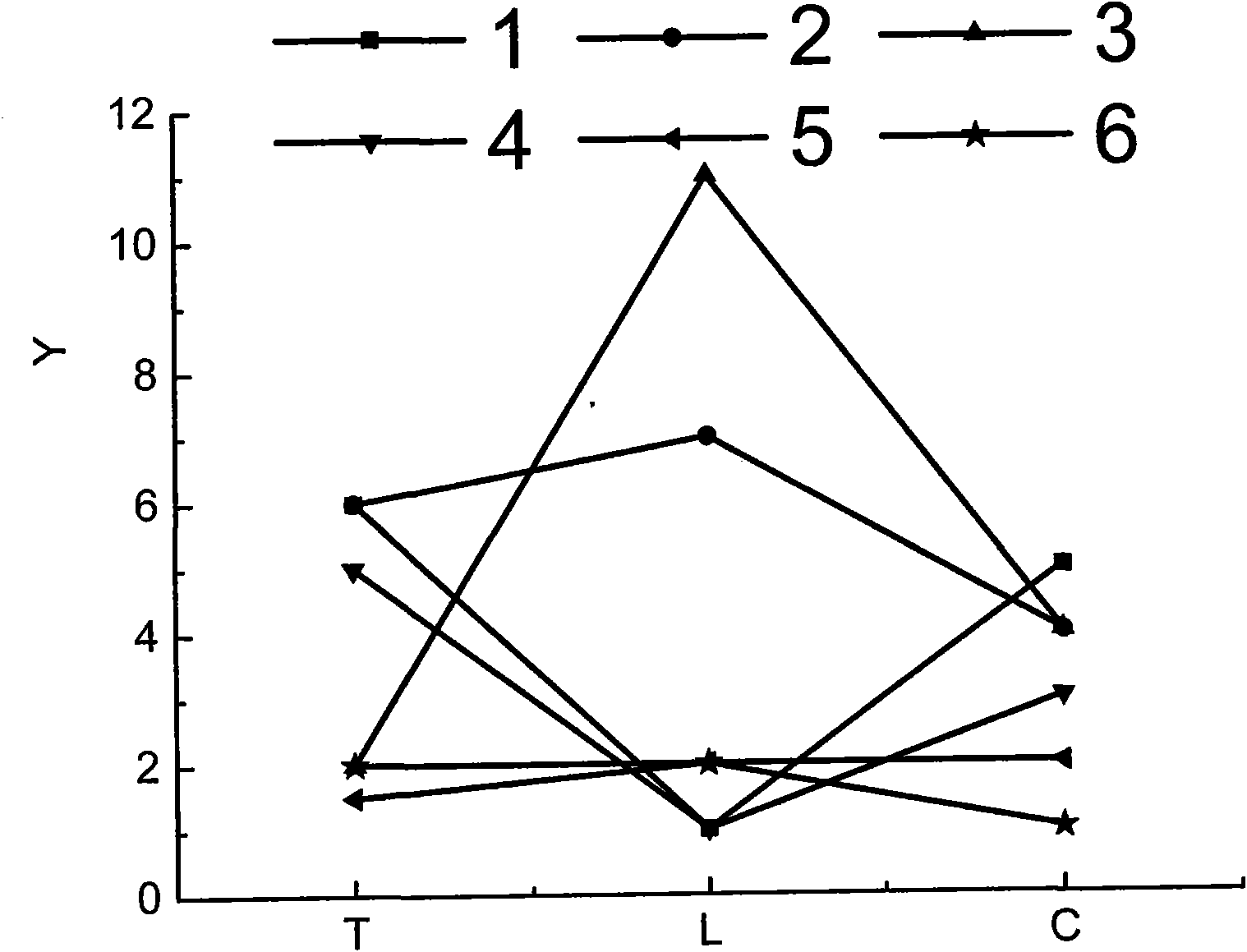

Examples

Embodiment Construction

[0028] During the development of Shougang’s hot-rolled high-strength steel coils, especially for products such as high-strength steel for construction machinery and automotive girder plates, users have very high requirements for the shape of the strip, that is, the residual stress. The residual stress in high-strength steel is mainly caused by non-uniform conditions such as temperature and phase transformation in the rolling process and cooling process of hot-rolled wide-band steel. In order to ensure the smooth development of hot-rolled high-strength steel products, especially for products with a yield strength level greater than or equal to 600MPa, it is necessary to eliminate and homogenize the residual stress inside the hot-rolled steel coil to ensure a good shape when the user uses it. quality. Although the temper rolling process can be used to improve the shape quality of the strip, it is difficult to control the shape of thin-gauge cold-rolled products, hot-rolled pickl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com