Verisimilitude briquette coal and gas outburst simulation test device and method

A technology of gas outburst and simulation test, which is applied in the direction of measuring device, fuel oil test, material inspection product, etc.

Active Publication Date: 2017-03-08

CHINA UNIV OF MINING & TECH +1

View PDF5 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Technical problem: The present invention aims at the demand and the existing problems in the prior art, and provides a realistic briquette and gas outburst simulation test device and method to solve the problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

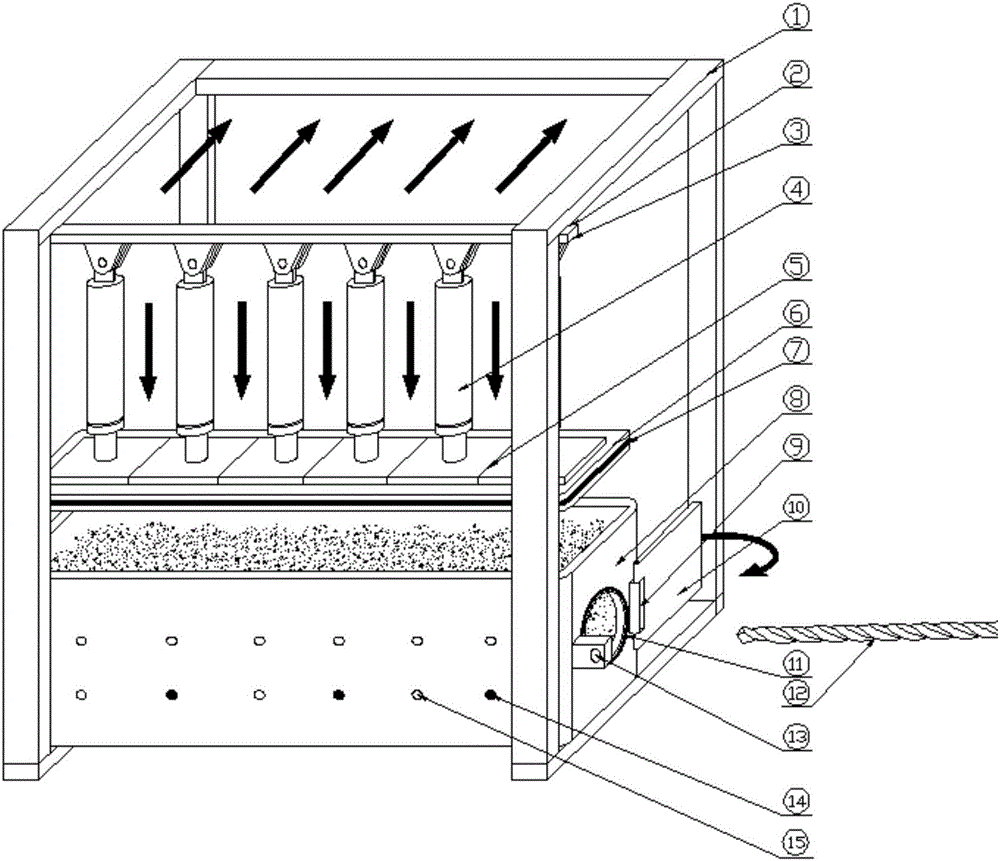

The invention provides a verisimilitude briquette coal and gas outburst simulation test device and method. Under the condition of the stress and gas pressure effects being accompanied by top plate motion, energy transfer and gas continuous supply, the coal body has three mechanics zones, receives the top plate effect and achieves the gas zoning distribution features, the coal and gas outburst evolution process in front of the work surface is really simulated. The device consists of a support frame, a cavity, a cover plate, a stress loading system, a gas injection system, a parameter recording system and a sealing opening. The three-zone stress is loaded and simulated through an oil cylinder in a zoning way; a cover plate with different thicknesses and rigidities simulates the top plate; the gas is sealed through a sealing strip between the cover plate and the cavity, so that the gas can maintain the zoned distribution; the coal wall delay outburst is exposed through screen net opening sealing simulation; the sealed sealing opening is suddenly opened to simulate the rock cross-cut coal uncovering outburst, and paraffin melting or hole drilling is used for simulating the digging outburst. The device and the method have the advantages that the coal and gas outburst environment, the influence factor, the boundary condition and the evolution generation process can be really simulated; the roadway-side stress and gas coupling effect and the evolution process can be simulated.

Description

technical field [0001] The invention relates to a coal and gas outburst simulation test device and method, in particular to a realistic briquette and gas outburst simulation test device and method. Background technique [0002] Coal (rock) and gas (methane or carbon dioxide) outburst, coal and gas extrusion, rock burst and other coal-rock dynamic disasters are the main disasters in high gas and deep coal mining. With the increase of mining depth and mining intensity, coal-rock dynamic disasters such as mine gas outburst and rock burst have become increasingly serious and complex, and the risk of disasters has increased significantly. At the same time, some mines that had no dynamic disasters or obvious signs are now also Gradually, it seriously threatens the life safety of underground workers and the normal production of mines. [0003] At home and abroad, a lot of research has been done on the mechanism, influencing factors, occurrence rules, prediction and prevention of p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/22

CPCG01N33/222G01N33/225

Inventor 王恩元欧建春王笑然何学秋李忠

Owner CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com