Method for preparing porous silicon carbon nanotube composite negative electrode material of lithium ion battery by diatomite

A technology of carbon nanotube composite and silicon-carbon composite materials, which is applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle stability of composite materials, high price of porous silicon materials, complicated preparation process, etc. Clear, low price, and simple preparation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 A kind of diatomite of embodiment 1 prepares the method for lithium-ion battery porous silicon carbon nanotube composite negative electrode material, prepares according to the following steps:

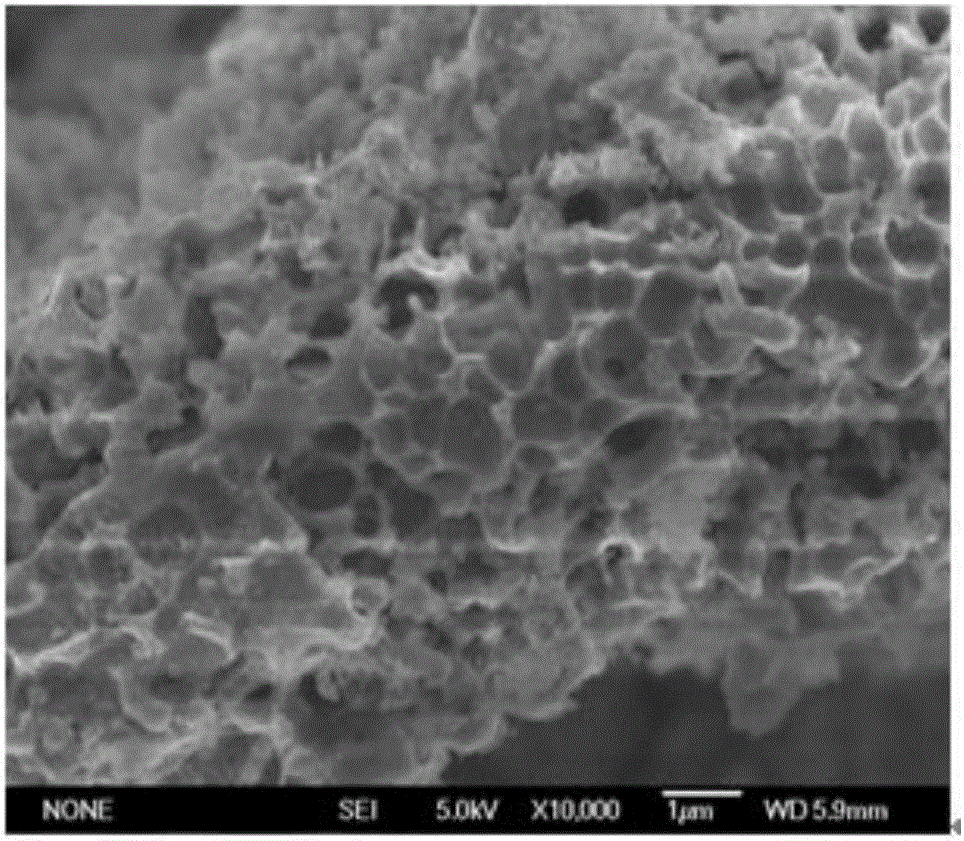

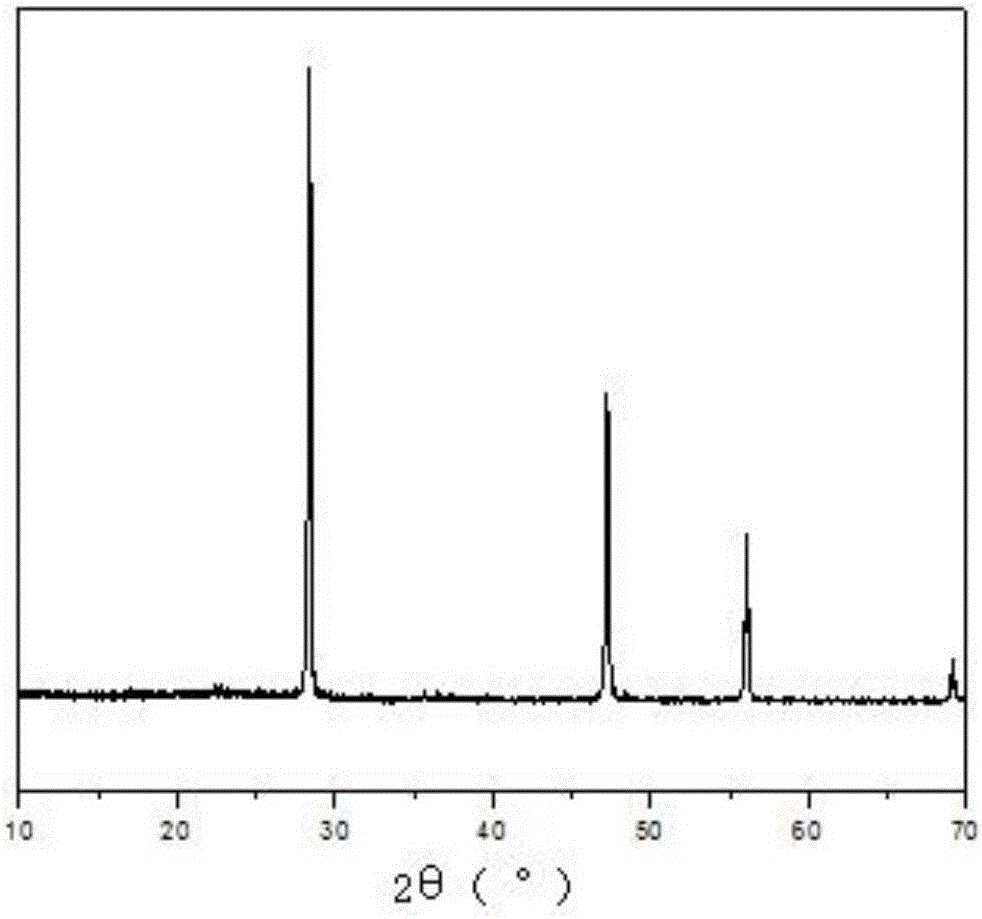

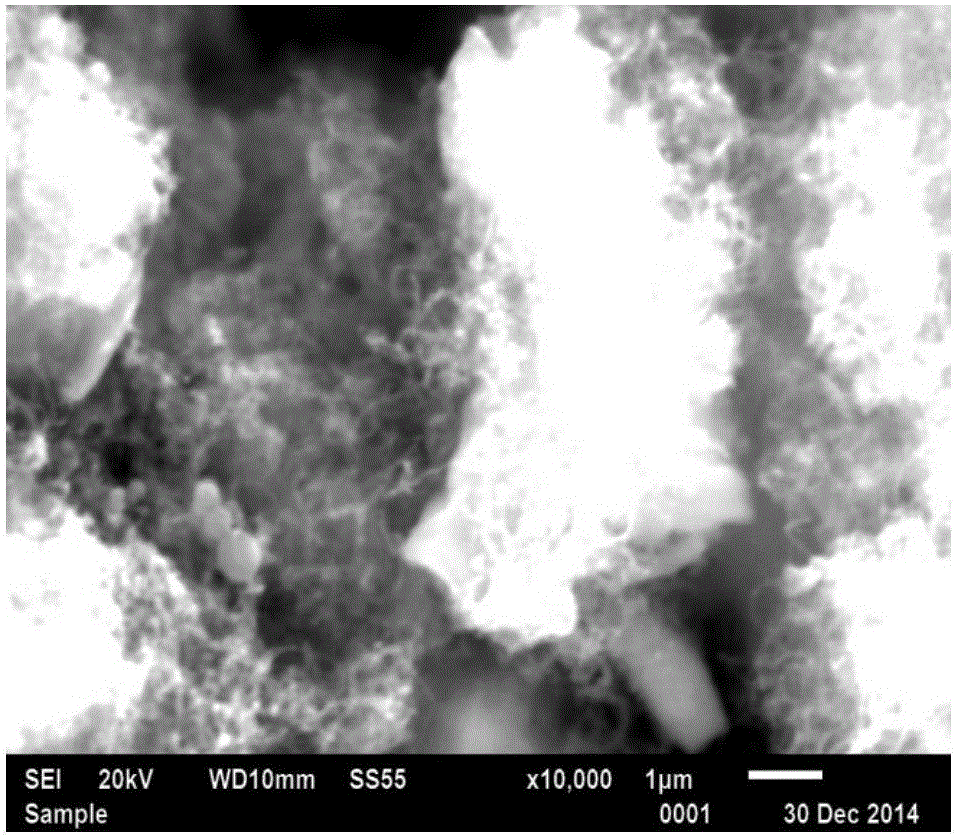

[0035] Grind natural diatomaceous earth and dissolve it in 0.01M sodium hydroxide aqueous solution, then filter and dry the suspension and collect it. Subsequently, diatomite is roasted in the air at 600°C for 2 hours to remove organic matter, and then poured into 95°C , 6M sulfuric acid solution to remove impurities such as iron oxide, aluminum oxide, magnesium oxide and calcium oxide. Finally, the purified diatomite is filtered, washed, and then dried to obtain purified diatomite. Mix the purified diatomaceous earth and magnesium powder at a mass ratio of 1:1, then place the homogeneously mixed sample in a muffle furnace, and bake it at 700°C for 3 hours in an argon atmosphere, until the temperature in the muffle furnace is naturally Take it out after cooling to ...

Embodiment 2

[0039] Example 2 A kind of diatomite of embodiment 2 prepares the method for lithium-ion battery porous silicon carbon nanotube composite negative electrode material, prepares according to the following steps:

[0040] Natural diatomaceous earth was ground and dissolved in 0.01M aqueous sodium hydroxide solution, and then the suspension was collected by filtration and drying. Subsequently, the diatomite was roasted in the air at 600°C for 2 hours to remove organic matter, and then poured into 95°C, 6M sulfuric acid solution to remove impurities such as iron oxide, aluminum oxide, magnesium oxide and calcium oxide. Finally, the purified diatomite is filtered, washed, and then dried to obtain purified diatomite. Mix purified diatomaceous earth and magnesium powder at a mass ratio of 1:1, then place the uniformly mixed sample in a muffle furnace, and bake it at 650°C in an argon atmosphere for 5 hours, and wait for the temperature in the muffle furnace to cool naturally Take ...

Embodiment 3

[0044] Example 3 A kind of diatomite of embodiment 3 prepares the method for lithium-ion battery porous silicon carbon nanotube composite negative electrode material, prepares according to the following steps:

[0045] Natural diatomaceous earth was ground and dissolved in 0.01M aqueous sodium hydroxide solution, and then the suspension was collected by filtration and dried. Subsequently, the diatomite was roasted in the air at 600°C for 2 hours to remove organic matter, and then poured into 95°C, 6M sulfuric acid solution to remove impurities such as iron oxide, aluminum oxide, magnesium oxide and calcium oxide. Finally, the purified diatomite is filtered, washed, and then dried to obtain purified diatomite. Mix the purified diatomaceous earth and magnesium powder at a mass ratio of 1.5:1, then place the homogeneously mixed sample in a muffle furnace, and bake it at 700°C for 3 hours in an argon atmosphere, until the temperature in the muffle furnace is naturally After co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com