Preparing method for carbon nano tube foam material

A carbon nanotube, foam material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of easy removal, wide material sources, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a. Select a synthetic polymer foam material, and a polyurethane sponge with a size of 20cm×10cm×4cm is completely immersed in 5mM CuCl 2 In the aqueous solution, after fully soaking for 60 minutes, take out the sponge, place it in a vacuum oven until it is completely dry, and obtain a sponge loaded with metal copper ions;

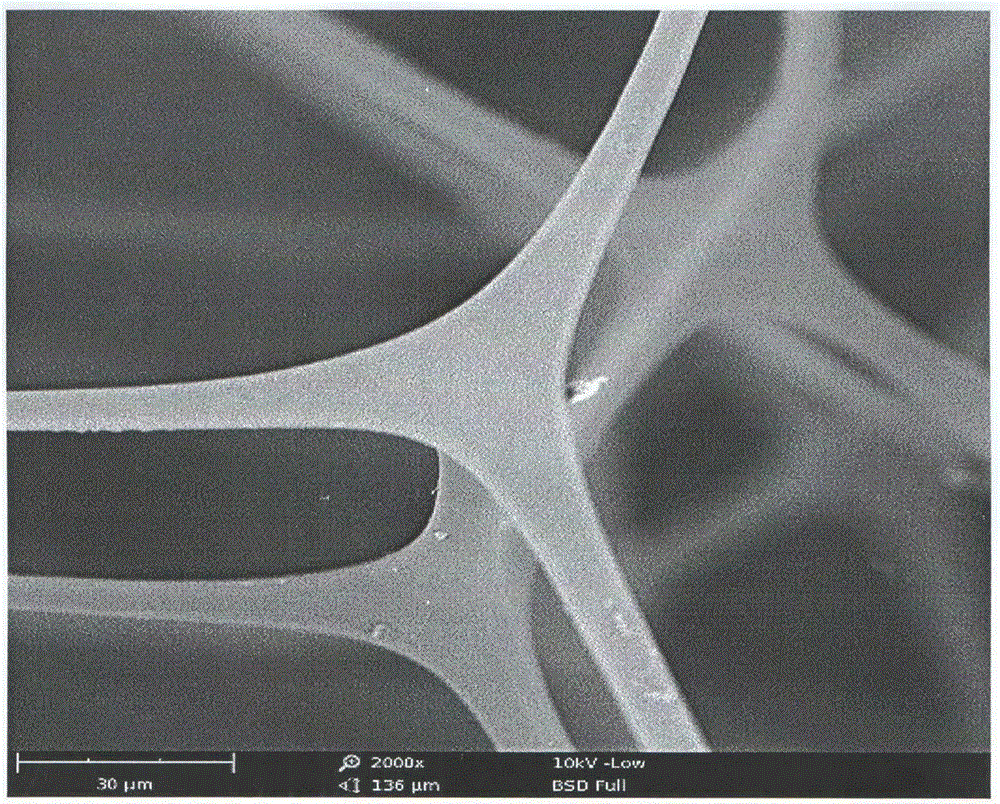

[0026] b. The obtained sponge loaded with metal copper ions is placed in a tube furnace, and in an atmosphere of inert gas argon (the flow rate of argon is 240 sccm), the temperature is raised to 600° C., and the temperature is maintained for 3 hours. The polyurethane sponge is alone in argon. After carbonization, its appearance is as image 3 ,Compared figure 2 and image 3 It can be clearly seen that the skeleton structure of the material is hollow after this step;

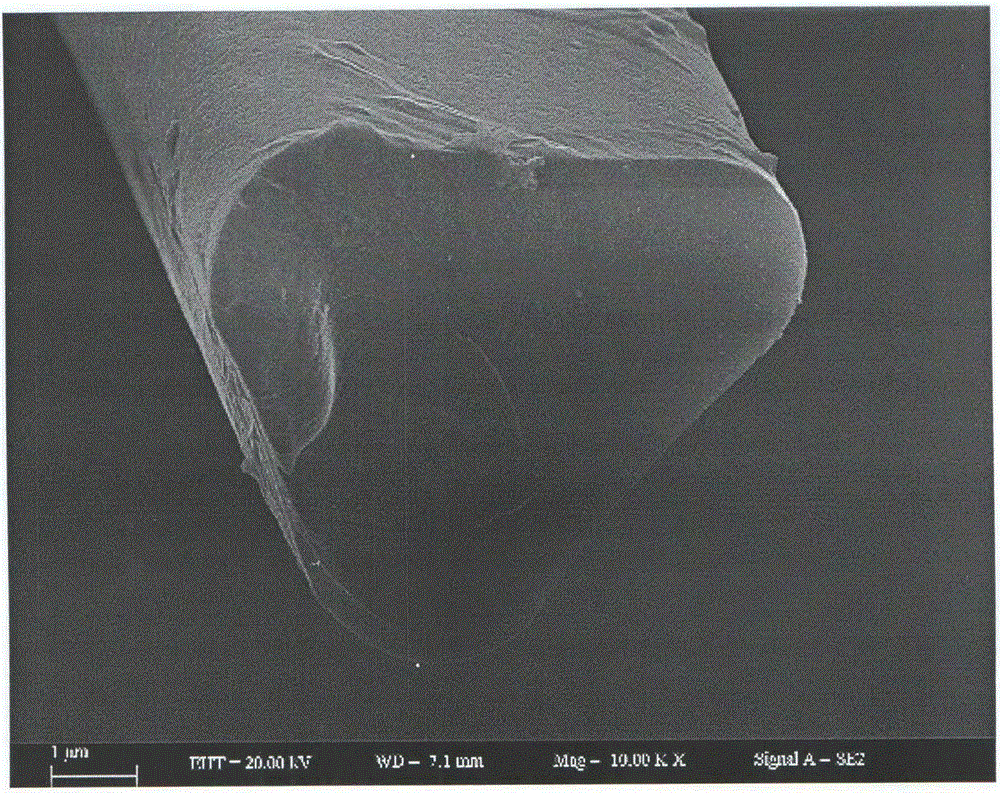

[0027] c. Then feed acetylene gas with a flow rate of 50 sccm as the carbon source gas, and keep the temperature at 600°C for 3 hours to grow carbon tubes. When the reaction temper...

Embodiment 2

[0029] a. The pellets with a diameter of 4 cm prepared from natural polymer bamboo fiber were completely immersed in 10 mM Co(NO 3 ) 2 ·6H 2 In the O aqueous solution, after fully soaking for 35 minutes, take out the sponge, place it in a vacuum oven until completely dry, and obtain a sponge loaded with metal cobalt ions;

[0030] b. Put the prepared sponge loaded with metal cobalt ions into a tube furnace, heat up to 650° C. in an inert gas nitrogen (flow rate of 240 sccm) atmosphere, and keep the temperature constant for 2 hours;

[0031] c. Then feed 50 sccm of ethylene gas as the carbon source gas, and keep the temperature constant for 1.5 hours at 650°C. After the reaction is over, stop the feeding of ethylene, and let the system naturally cool down to room temperature in an atmosphere of inert gas nitrogen to obtain Growth on carbon nanotube foam based on bamboo fibers.

Embodiment 3

[0033] a. Take the synthesized polymer foam material, and melamine sponge with a size of 20cm×10cm×4cm is completely immersed in 1mM Ni(NO 3 ) 2 ·6H 2 In the aqueous solution of O, fully immerse the sponge under ultrasonic for 40min, take out the sponge, place it in a vacuum oven until completely dry, and obtain the sponge loaded with metal nickel ions;

[0034] b. Put the prepared sponge loaded with metal nickel ions in a tube furnace, heat up to 700° C. in an atmosphere of inert gas helium (flow rate is 210 sccm), and keep the temperature constant for 2 hours;

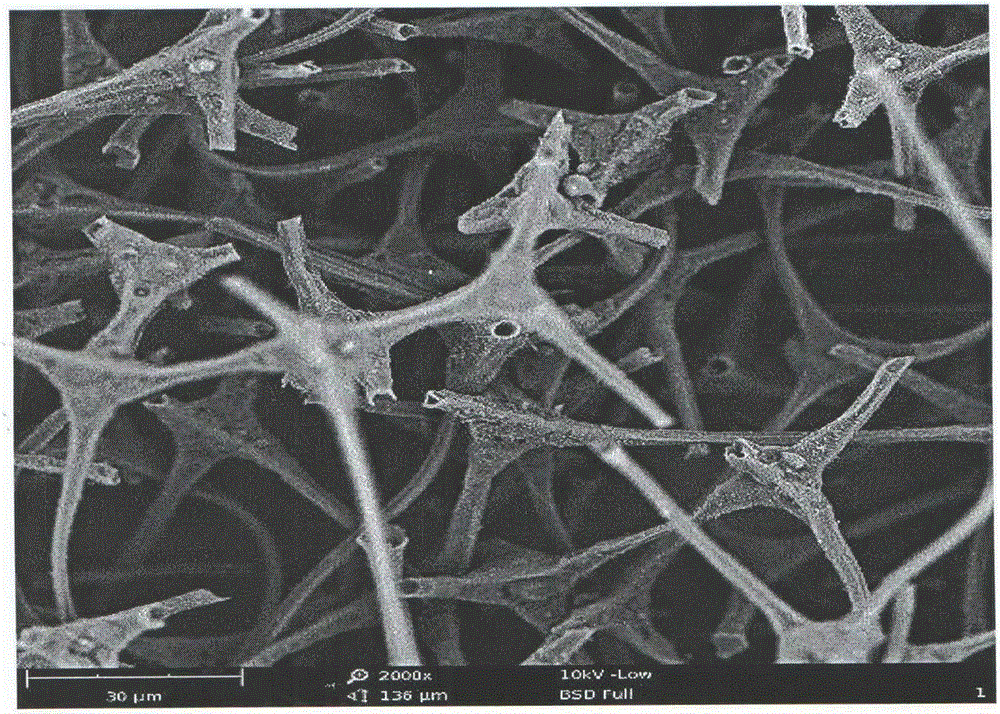

[0035] c. Then feed 40 sccm of methane gas as the carbon source gas, keep the temperature at 700° C. for 2 hours, stop the feeding of methane gas after the reaction is over, and allow the system to cool naturally to room temperature in an inert gas helium atmosphere, and obtain the same as Figure 6 A similar framework is a hollow carbon nanotube foam material, and its hydrophobic performance has been measured. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com