Ultrafine-grain hot-rolling dual phase steel plate for automobile and production method thereof

A technology of ultra-fine grains and production methods, applied in the direction of temperature control, etc., to achieve the effects of good hole expansion performance, uniform product quality and high formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

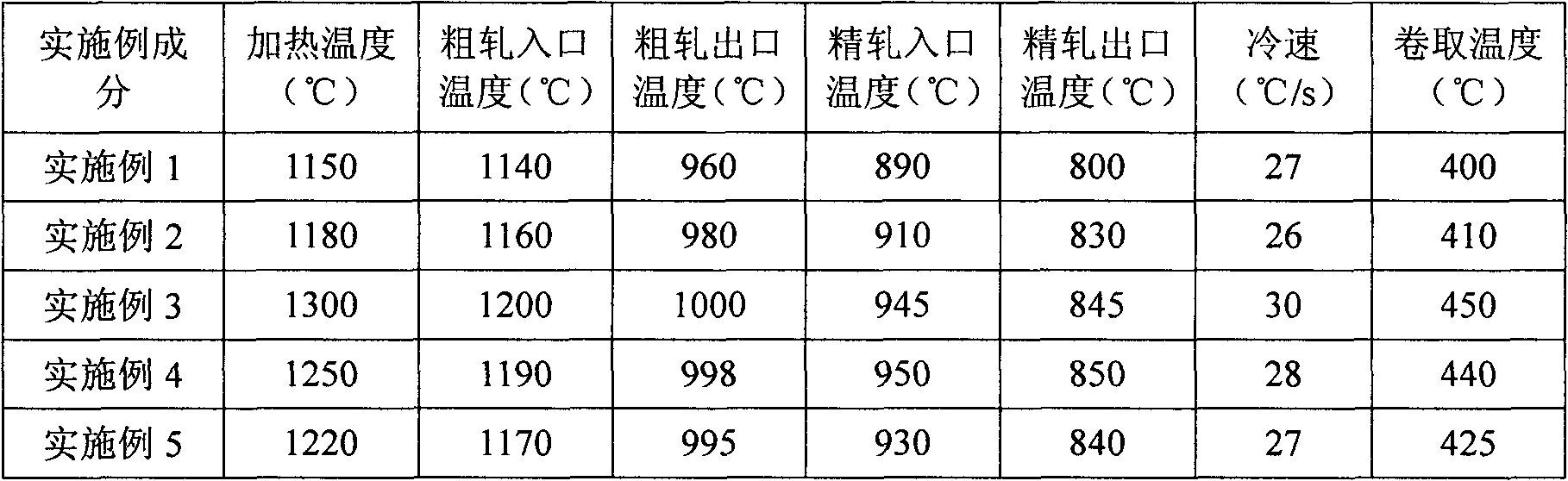

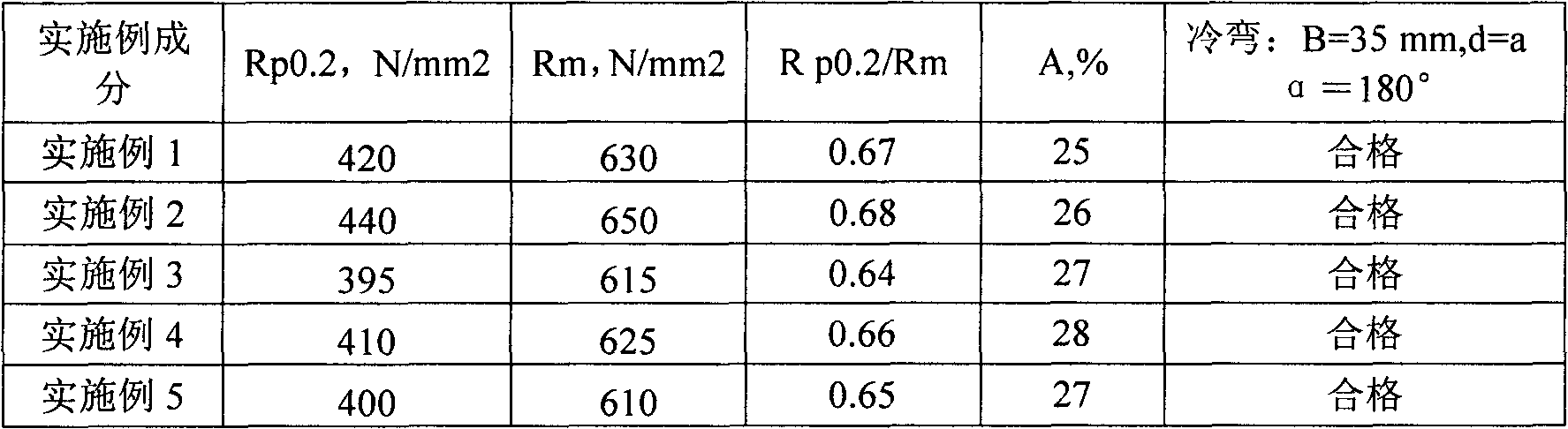

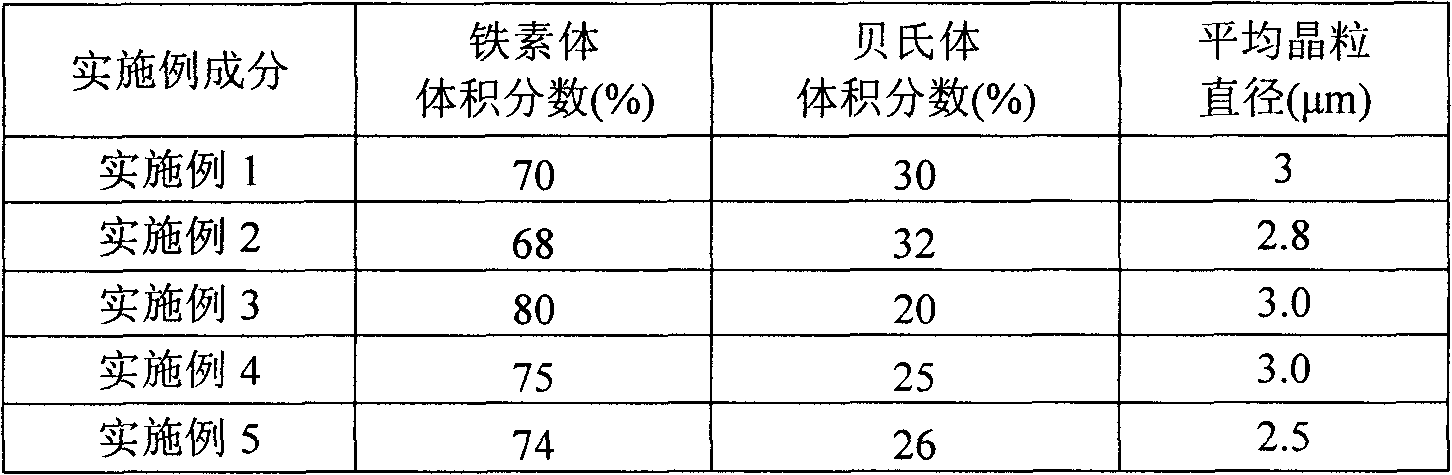

[0027] Examples of the invention are as follows: heat the continuous casting slab (200×1500mm) to 1150-1300°C, heat it for 2-3 hours, then carry out rough rolling, cover the heat preservation cover after the rough rolling, and then finish rolling under high pressure in multiple passes. The rolling temperature is 800-850°C, laminar flow cooling is adopted after rolling, and the coiling temperature is cooled to the coiling temperature at a cooling rate of 25-30°C / s, and the coiling temperature is 400-450°C. The finished thickness of the steel plate is 4mm. The specific steel composition of the five embodiments of the present invention is shown in Table 1, the actual rolling system is shown in Table 2, and the various performance indexes of the steel plate are shown in Table 3.

[0028] Table 1 Melting composition (wt, %) of dual-phase steel plate of the present invention

[0029] Example ingredients

C

Si

mn

P

S

Nb

Example 1

0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com