Drink extraction mechanism

A beverage and driving mechanism technology, applied in beverage preparation devices, kitchen utensils, household appliances, etc., can solve problems affecting safety and stability, no mechanical pre-foaming, inconvenient operation, etc., to achieve increased safety and stability, high safety, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

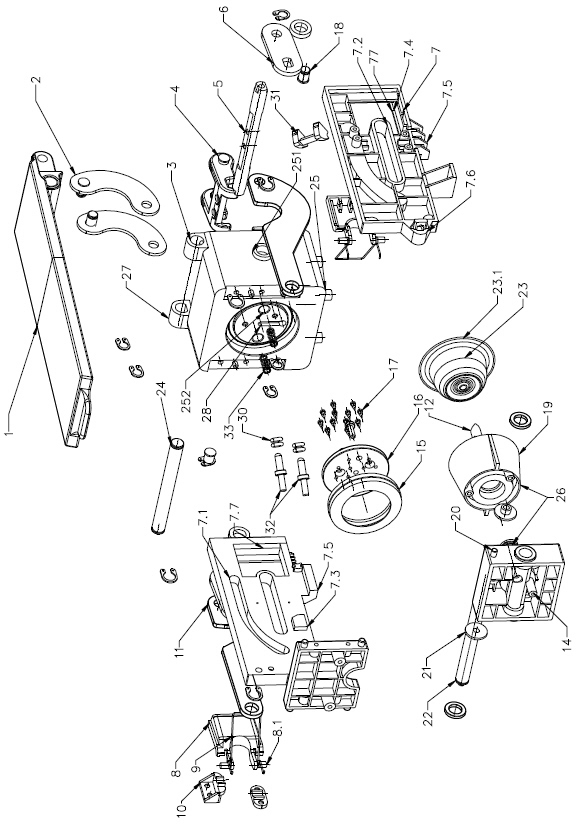

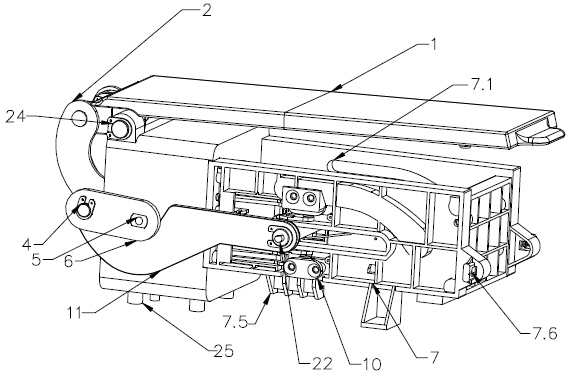

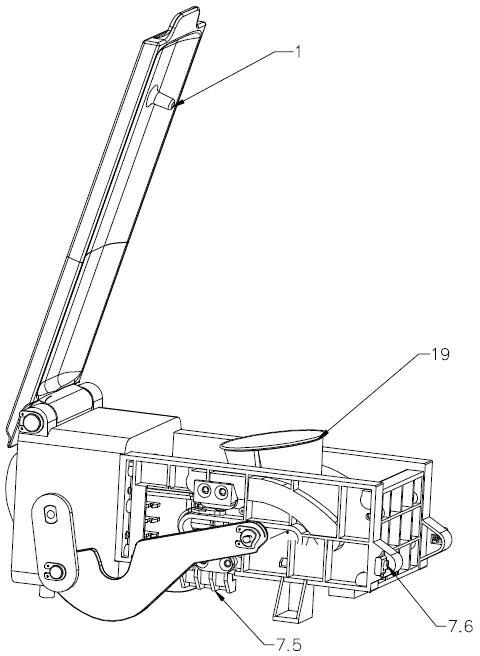

[0031] The structure diagram of the present invention is as figure 1 As shown, the beverage extraction mechanism of the present invention includes a beverage brewing mechanism 26 installed on the brewing seat 25, and a driving mechanism 27 that drives the beverage brewing mechanism 26 to realize opening and closing and flipping motions, wherein the driving mechanism 27 The guidance of the guide mechanism 7 drives the beverage brewing mechanism 26 to realize opening and closing and overturning movement, and when the beverage brewing mechanism 26 is opened and closed, the mouth of the brewing cavity faces upward or obliquely upward, and the driving mechanism 27 is also connected to the beverage brewing mechanism. After the mechanism 26 completes coffee brewing, after the brewing cavity 19 in the beverage brewing mechanism 26 is gradually separated from the coffee capsule 23, the ejector mechanism will push out the capsule 23 still adsorbed on the brewing seat 25.

[0032]In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com