A vertical capsule brewing device for a coffee machine

A technology for a brewing device and a coffee machine, which is applied to beverage preparation devices, applications, kitchen utensils, etc., can solve the problems of high manufacturing cost and troublesome operation, and achieve the effects of convenient operation, simple structure and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below by referring to the accompanying drawings and by describing the embodiments.

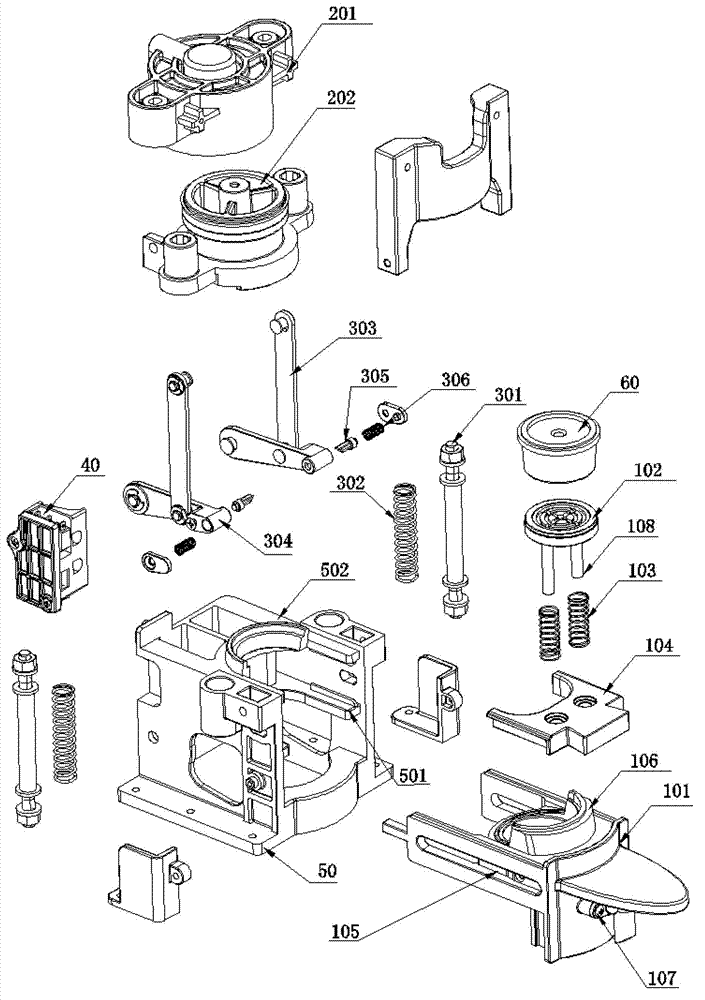

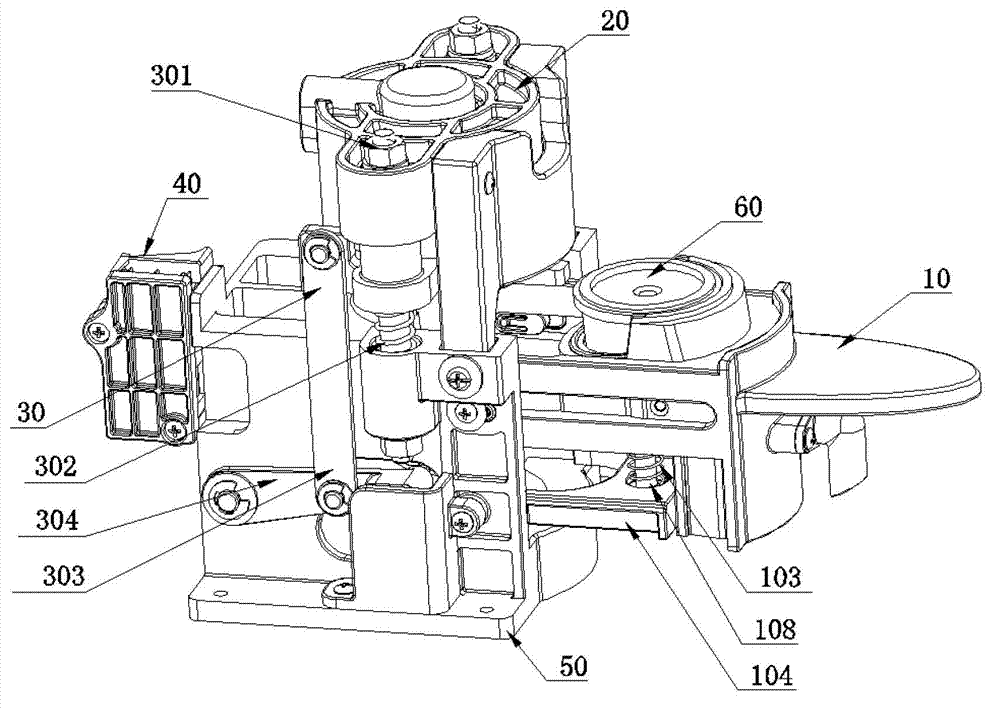

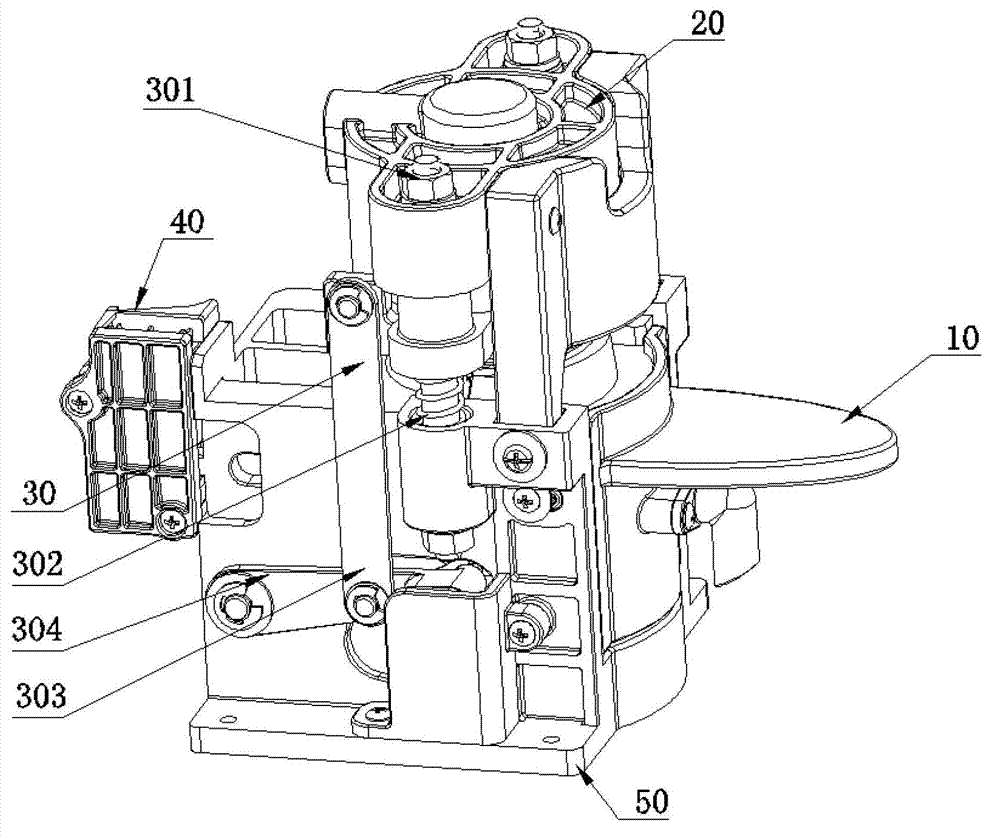

[0034] like figure 1 , figure 2 , image 3 As shown, the vertical capsule brewing device for coffee machines provided by the present invention includes a brewing chamber assembly 10 , a hydraulic assembly 20 , a transmission assembly 30 , a switch assembly 40 and a bracket 50 .

[0035] like figure 1 , figure 2 , image 3 As shown, the brewing chamber assembly 10 of the present invention is arranged on a support 50 and can be drawn back and forth on the support 50 . The brewing chamber assembly 10 includes a brewing chamber 101 , a capsule top block 102 , a top block spring 103 and a sliding plate 104 . The brewing chamber 101 includes a cylindrical cavity, on which two wings are symmetrically arranged, and a chute 105 is respectively arranged on the two side wings, and a slide rail 501 matched with the chute 105 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com