Automatic capsule dropping coffee machine

A technology for coffee machines and capsules is applied in the field of automatic capsule-dropping coffee machines, which can solve the problems of only being installed on one side of the body, increasing the volume of the whole machine, and restricting the shape design, and achieves low manufacturing cost, small volume, and convenient production. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

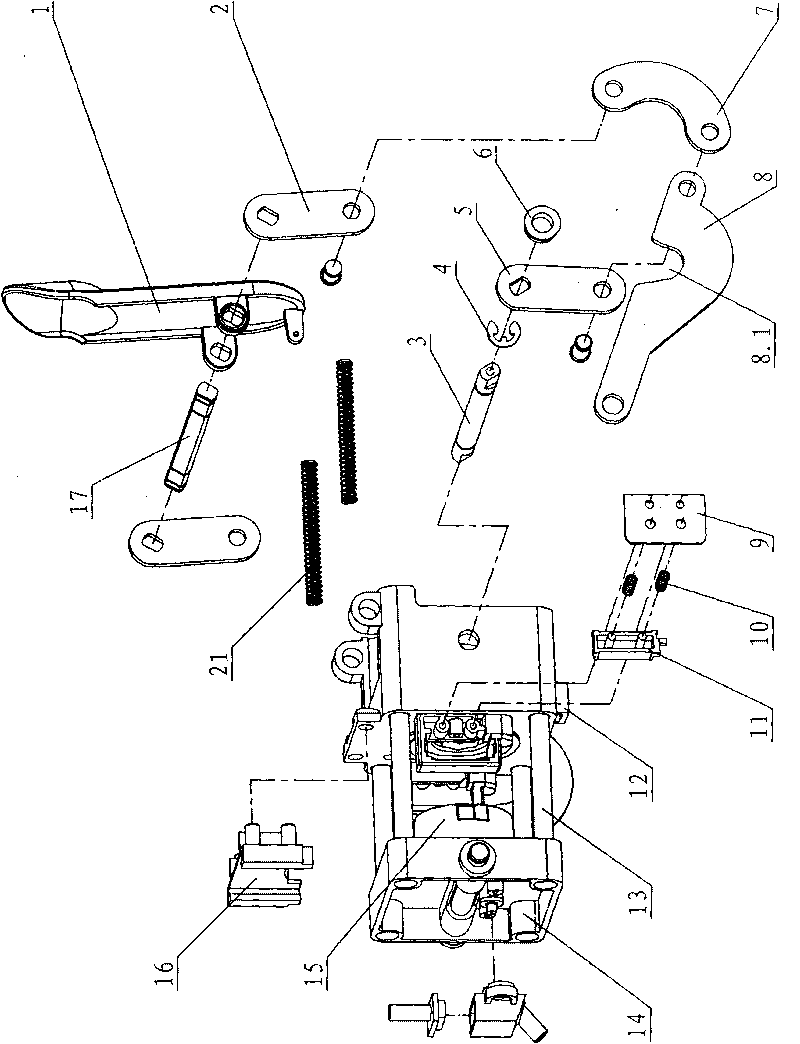

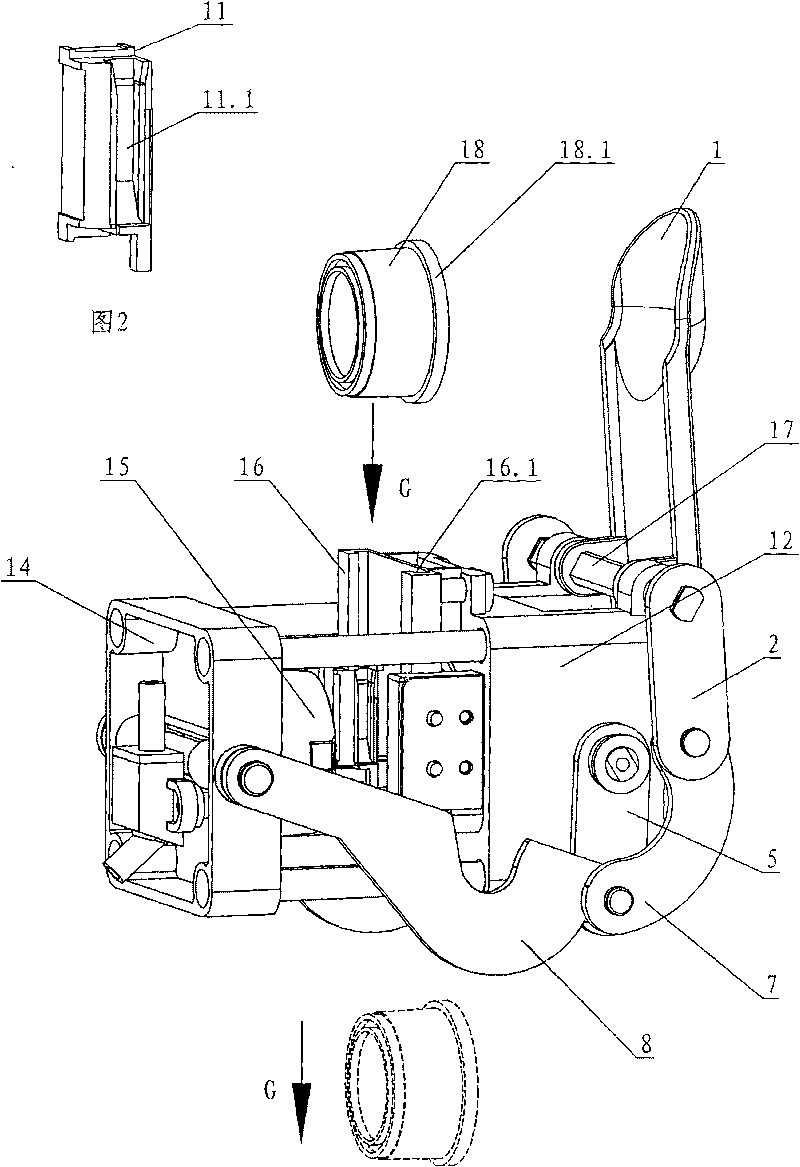

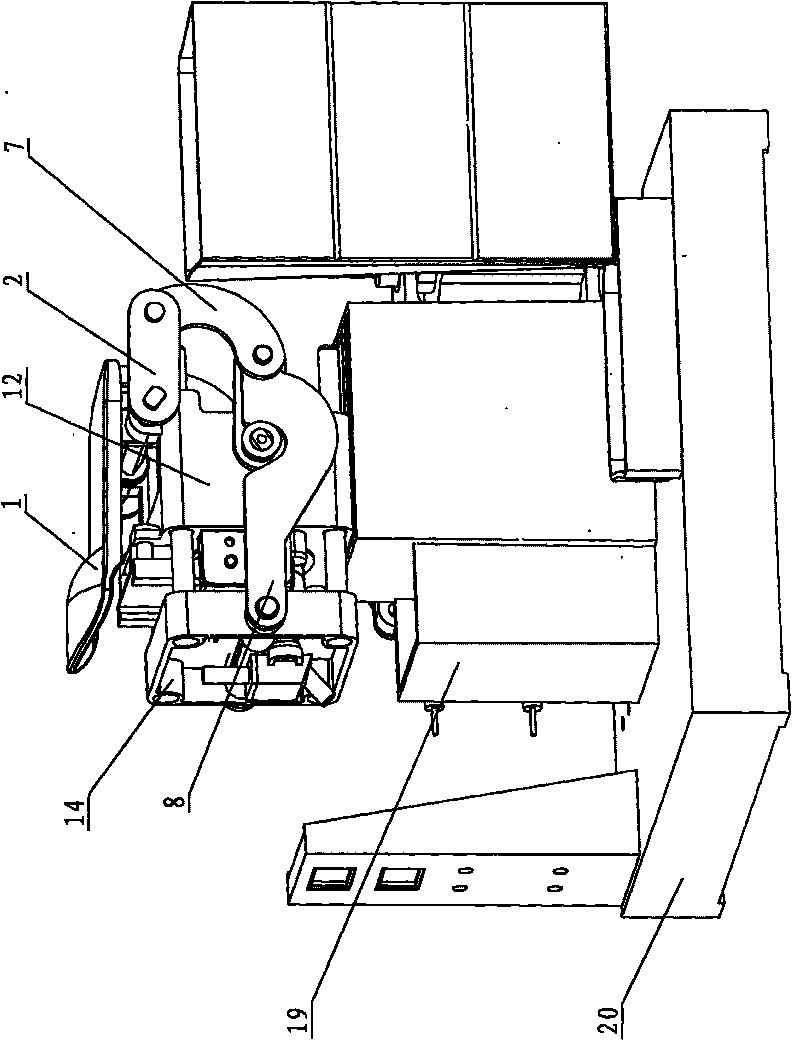

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] see Figure 1-Figure 8 , the automatic capsule coffee machine includes a water outlet assembly 14 and an inlet water assembly 12 that move along a straight line through a driving mechanism. The hot water channel for brewing coffee capsules and the one-way valve 12.2 are arranged at the end, see Figure 7 The surface of the coffee capsule is ring-shaped with a flange 18.1, the brewing chamber is fixed at the inner end of the water outlet assembly, and the opening of the coffee capsule is placed towards the hot water channel and the one-way valve; the left and right sides of the inner end of the water inlet assembly are provided with left and right sliding The movable clamping block 11 is provided with a card slot 11.1 corresponding to the flange of the coffee capsule. The water entry body assembly 12 is arranged on the machine base 20 , and a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com