Method for synthesizing ZSM-5 molecular sieve through two-segment temperature change

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the temperature gradient of the synthesis system and the uneven distribution of gel components, and the crystallization of molecular sieve products In order to solve problems such as poor degree of stability and decreased equipment utilization rate, it can achieve the effects of narrow grain size distribution, good fluidity and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

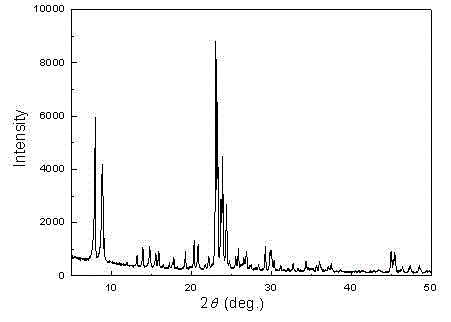

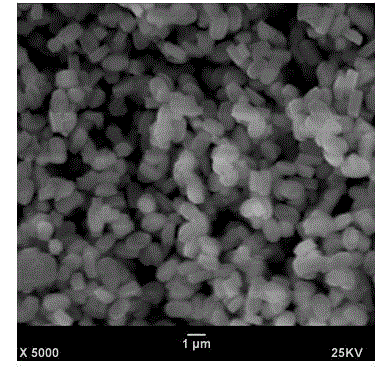

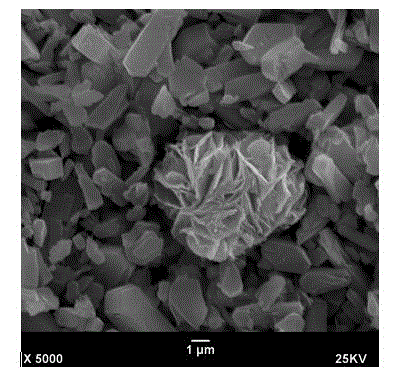

[0023]Mix 39.15 g of water glass (modulus 2.98) with 1.47 g of n-butylamine and 15 g of deionized water in a stainless steel synthesis kettle with a volume of 200 ml and stir evenly to prepare A solution; mix 0.72 g of aluminum sulfate and 2.27 g of sulfate (98%) and 24 g deionized water were stirred in a 50 ml beaker to prepare B solution. Slowly add solution B to solution A while stirring, then add 50 g of deionized water, stir for 0.5 h to obtain an initial reaction gel, add 200 mg of ZSM-5 seed crystals and seal. Under stirring, the temperature was first raised to 105°C for dynamic crystallization for 14 h, and then the temperature was raised to 125°C for dynamic crystallization for 26 h. After the product was cooled down, it was removed from the synthesis kettle, washed three times with deionized water, and dried at 120°C for 4 hours to obtain a ZSM-5 molecular sieve with a crystallinity of 100%. The product SiO 2 / Al 2 o 3 (mol ratio) was 69.

Embodiment 2

[0029] Mix 39.15 g of water glass (modulus 2.98) with 5.38 g of tetrapropylammonium bromide and 25 g of deionized water in a stainless steel synthesis kettle with a volume of 200 ml and stir evenly to prepare A solution; mix 0.72 g of aluminum sulfate, 2.27 g of sulfuric acid (98%) and 24 g of deionized water were stirred evenly in a 50 ml beaker to prepare B solution. Slowly add solution B to solution A while stirring, then add 40 g of deionized water, stir for 0.5 h to obtain an initial reaction gel, add 200 mg of finished ZSM-5 seed crystals and seal. Under stirring, the temperature was first raised to 110°C for dynamic crystallization for 10 h, and then the temperature was raised to 125°C for dynamic crystallization for 26 h. After the product was cooled down, it was removed from the synthesis kettle, washed three times with deionized water, and dried at 120°C for 4 hours to obtain a ZSM-5 molecular sieve with a crystallinity of 95%. The product SiO 2 / Al 2 o 3 (mol rat...

Embodiment 3

[0031] In a stainless steel synthesis kettle with a volume of 200 ml, 39.15 g of water glass (modulus 2.98) was mixed with 1.47 g of n-butylamine and 15 g of deionized water and stirred evenly to prepare A solution; 1.50 g of aluminum sulfate and 2.27 g of sulfuric acid ( 98%) and 24 g of deionized water were stirred in a 50 ml beaker to prepare B solution. While stirring, solution B was slowly added to solution A, and then 30 g of deionized water was added, and the initial reaction gel was obtained after stirring for 0.5 h. Add 250 mg of finished ZSM-5 seeds and seal. Under stirring, the temperature was first raised to 105 °C for dynamic crystallization for 12 h, and then the temperature was raised to 120 °C for dynamic crystallization for 32 h. After the product was cooled down, it was removed from the synthesis kettle, washed three times with deionized water, and dried at 120°C for 4 hours to obtain ZSM-5 molecular sieve, with a crystallinity of 99%, and the product SiO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com