Yarn strength weak ring detection and elimination method and apparatus

A yarn and strength technology, which is applied in the field of yarn strength and weak ring detection and removal, can solve problems affecting production efficiency and benefits, yarn strength reduction, and tensile resistance reduction, so as to improve production efficiency and benefits, Reduce downtime parking and increase the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

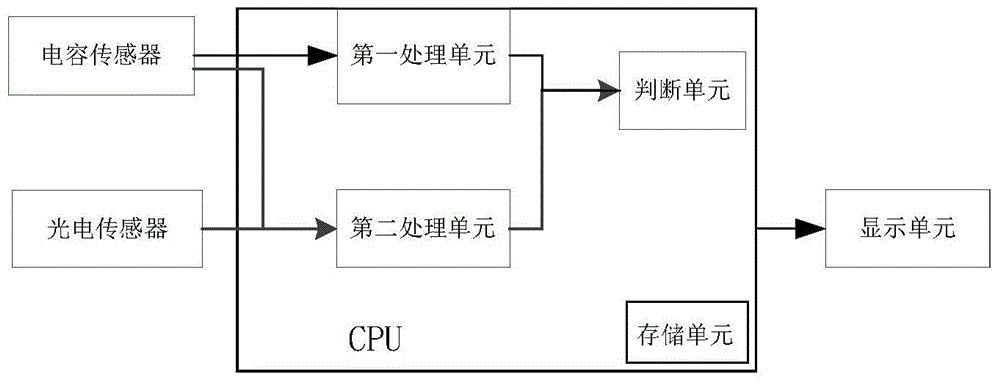

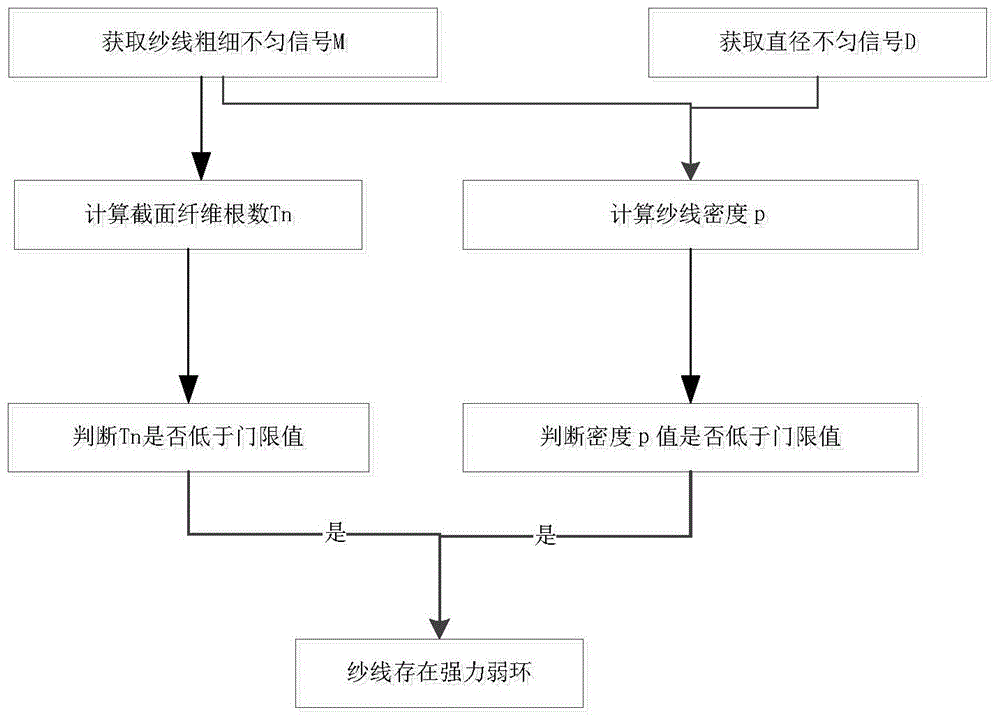

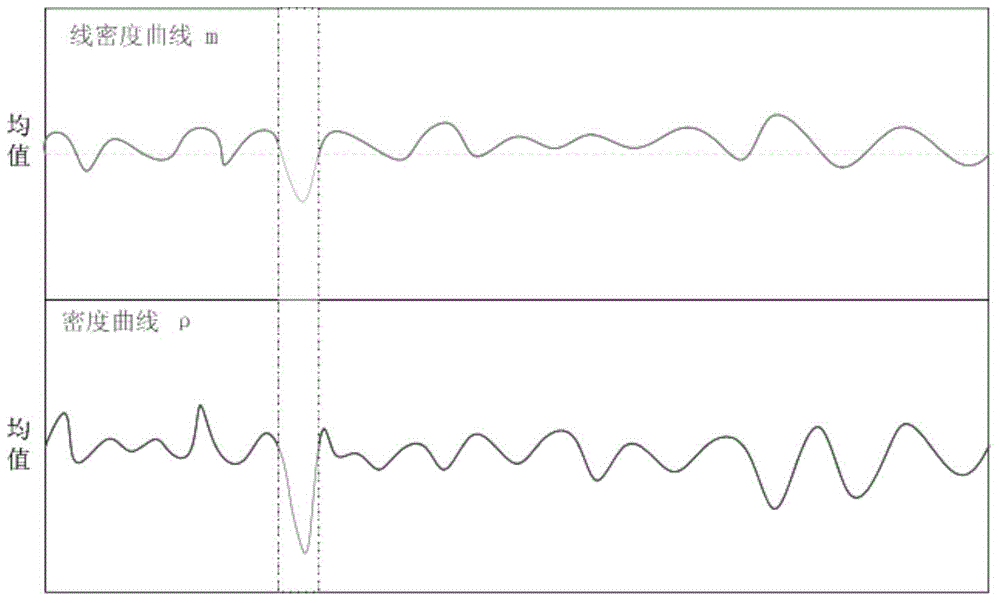

[0035] Such as figure 1 As shown in the present invention, a device for detecting and removing weak rings of yarn strength includes a capacitive sensor for obtaining a signal of uneven thickness of the yarn passing through a capacitive sensor test slot, and a photoelectric sensor for obtaining yarn The uneven diameter signal D of the thread passing through the photoelectric sensor test groove; the CPU, including the first processing unit, calculates the number of fibers in the yarn section Tn according to the linear relationship between the number of fibers in the yarn section Tn and the yarn linear density M; The second processing unit, according to the formula Calculate the yarn density ρ value; the judging unit judges whether the density p value is lower than the p value threshold v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com