High-count high-density cotton-nylon double-layer cloth and weaving process thereof

A high-count, high-density, double-layer technology, applied to textiles, papermaking, fabrics, textiles, etc., can solve the problems of no three-dimensional effect and gloss, and achieve the effects of avoiding the difficulty of splitting, comfortable and elastic, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below by the following examples, which will help to understand the present invention, but do not limit the content of the present invention.

[0039] Embodiment one Domestic double-layer fabrics are mainly based on two types of yarn counts, and the fabrics are mostly double-layer weaves of the same basic structure, without three-dimensional effect and luster.

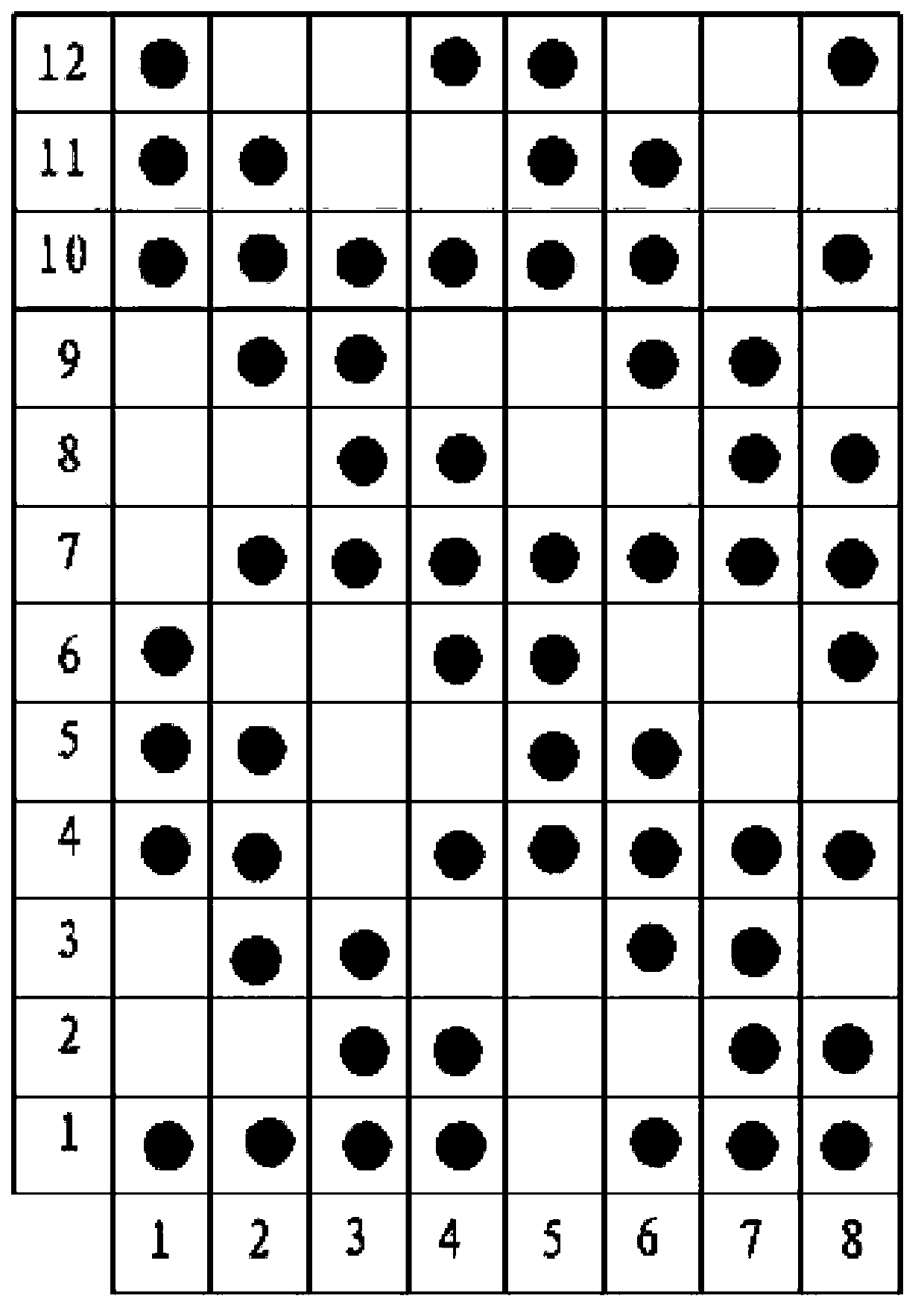

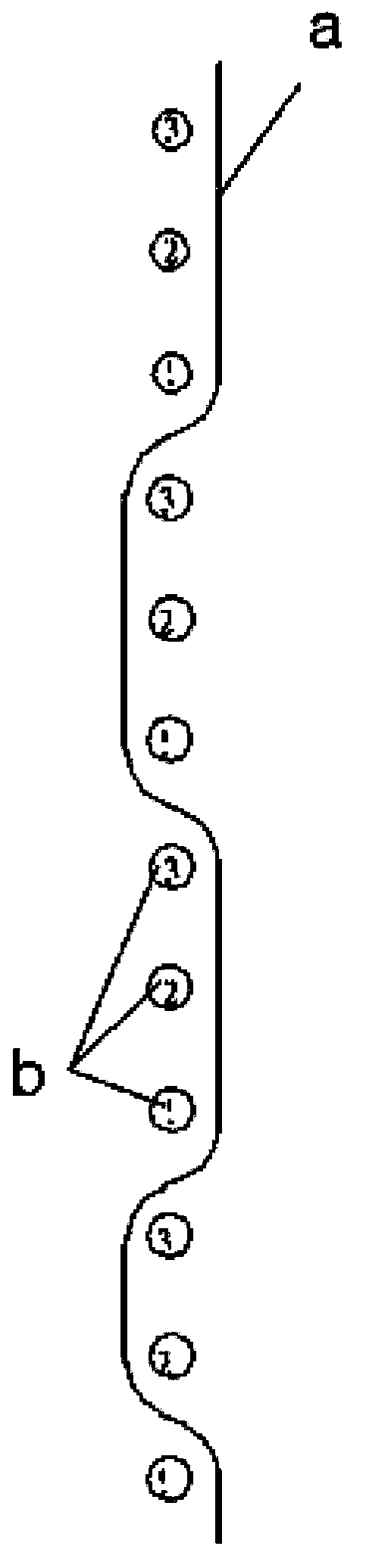

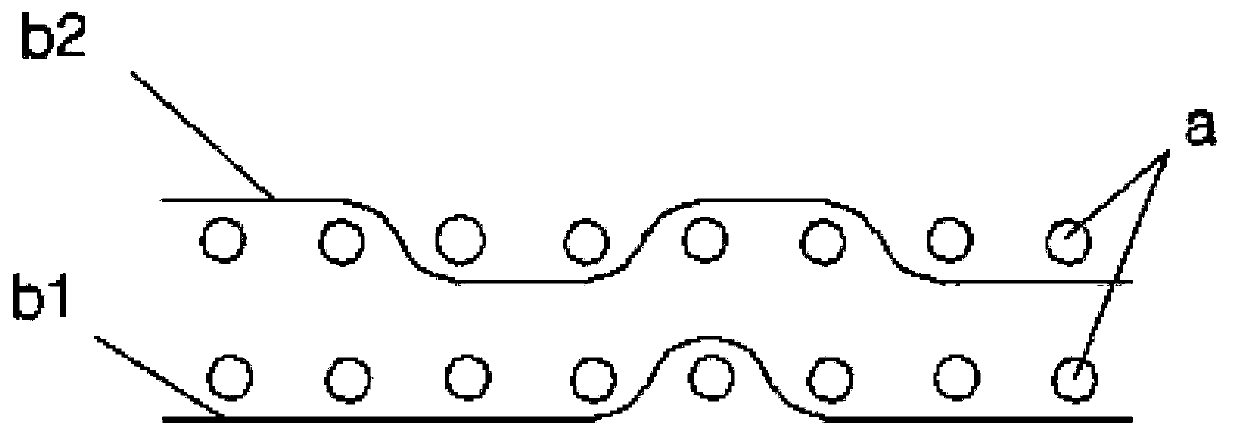

[0040] A kind of high-count high-density cotton-nylon double-layer cloth of the present invention, such as Figures 2 to 3 As shown, the warp yarn used is high-count combed cotton 9.7tex compact spun yarn, and the ratio of the three weft yarns is 1:1:1. figure 1 It is double weft with two upper and two lower twill plus eight irregular satin weaves, see attached figure 1 In , black dots indicate that warp yarns float on weft yarns, and blank dots indicate that weft yarns float on warp yarns. see attached section figure 2 Among them, a is high-count combed cotto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com