High-shrinkage staple fiber knitted fabric with anti-wrinkle and wind-proof performance and production method of knitted fabric

A manufacturing method and high-shrinkage technology, applied in knitting, weft knitting, textiles and papermaking, etc., to achieve small shrinkage, increase the application range, and expand the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

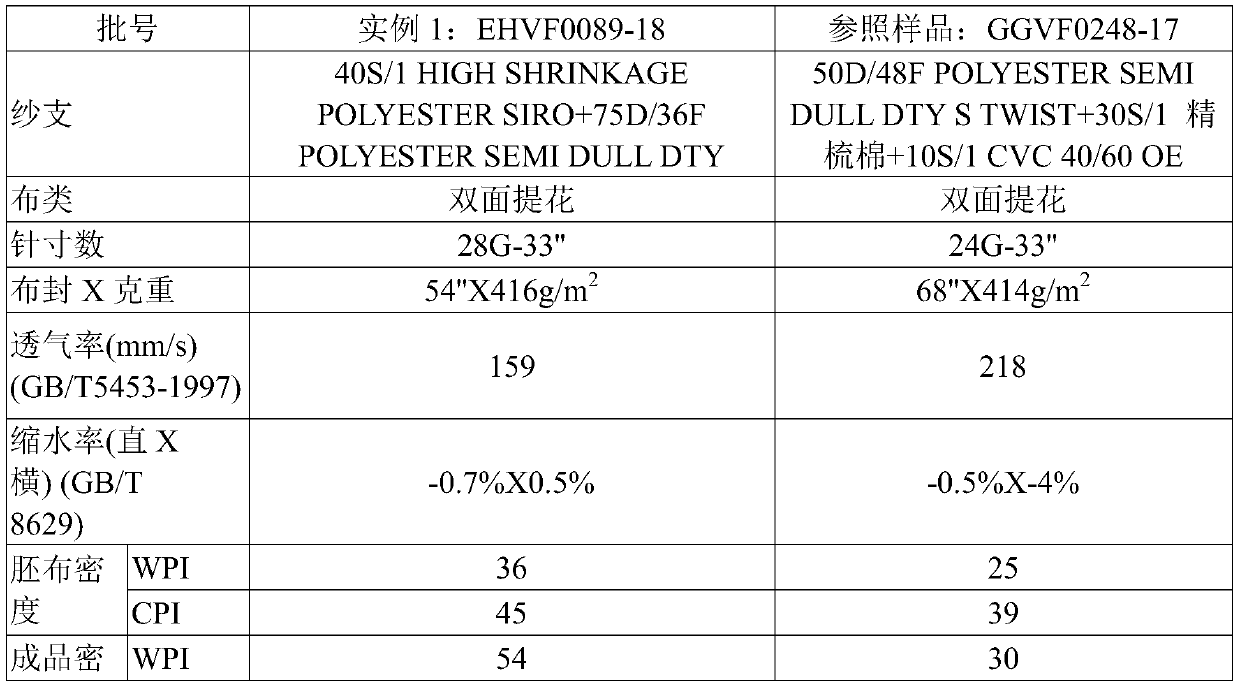

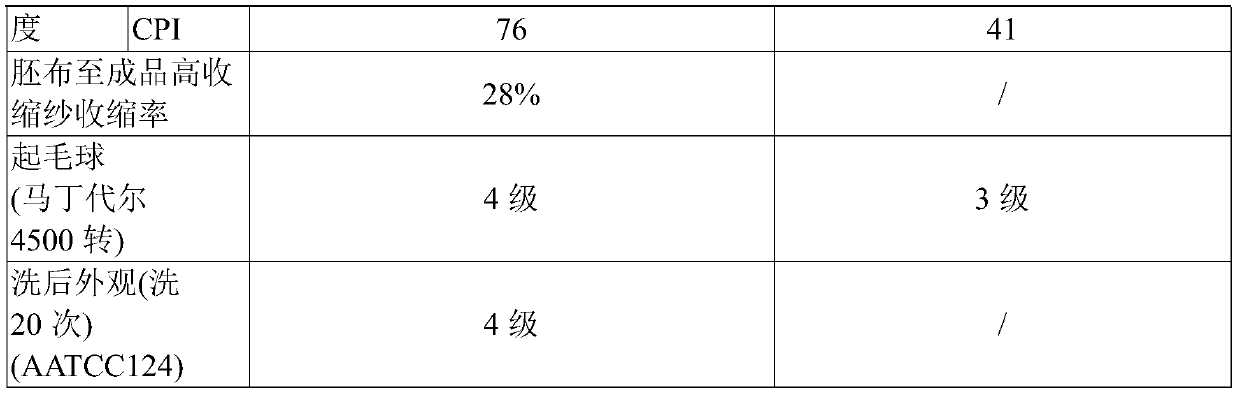

Embodiment 1

[0024] Embodiment 1: A kind of high-shrinkage short-fiber knitted fabric with anti-wrinkle and windproof performance is spun into single yarn (40S / 1HIGH SHRINKAGE POLYESTER SIRO) and ordinary polyester by 100% high-shrinkage polyester staple fiber with boiling water shrinkage rate of 50%. After the filament (75D / 36F POLYESTER SEMI DULL DTY) is woven by a circular knitting machine, the fabric embryo is woven. The specific manufacturing method is as follows:

[0025] (21) Spinning: Spinning high-shrinkage short fibers with boiling water shrinkage rate of 50% by 100% ratio through siro spinning to obtain high-shrinkage yarn count 40S / 1HIGH SHRINKAGE POLYESTER SIRO;

[0026] (22) Adjust the 40S / 1HIGH SHRINKAGE POLYESTER SIRO and 75D / 36F POLYESTER SEMI DULLDTY warp and weft knitting circular knitting machines, adjust the thread length to 15.5(40S) / 21cm(75D) / 100G, adjust the cylinder opening height to 1.5mm, and the cloth frame width At 100cm, the degree of cloth rolling is 45, the ...

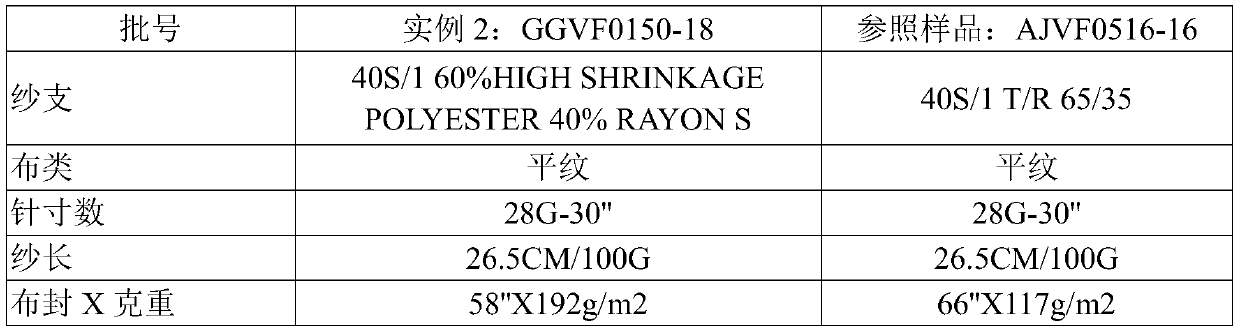

Embodiment 2

[0042] Embodiment 2: A kind of high-shrinkage short-fiber knitted fabric with anti-wrinkle and windproof performance is spun into single yarn (40S / 1 60% HIGHSHRINKAGE POLYESTER 40% RAYON) and then the cloth embryo is woven by a circular knitting machine. The specific manufacturing method is:

[0043] (21) Spinning: Spinning high shrinkage staple fibers with a boiling water shrinkage rate of 45% and rayon staple fibers in a ratio of 60:40 through siro spinning to obtain high shrinkage 40S / 1 60% HIGH SHRINKAGE POLYESTER 40% RAYON yarn;

[0044] (22) Use 40S / 1 60% HIGH SHRINKAGE POLYESTER 40% RAYON warp and weft knitting circular knitting machine, adjust the thread length to 26.5cm / 100G, the cloth frame width to 105cm, the cloth rolling degree to 30°, and the food position of the loom to In the middle, the speed of the loom is 25 rpm, and the cloth embryo can be woven by a weft-knitting single-jersey circular knitting machine;

[0045] (23) In order to prevent the high-shrinka...

Embodiment 3

[0060] Example 3: A high-shrinkage short-fiber knitted fabric with anti-wrinkle and windproof properties, which is spun into a single yarn (40S / 1 40 %HIGH SHRINKAGEPOLYESTER 60% POLY) and then the cloth embryo is woven by a circular knitting machine. The specific manufacturing method is:

[0061] (21) Spinning: Spin the high-shrinkage staple fiber with a boiling water shrinkage rate of 50% and ordinary polyester staple fiber in a ratio of 40:60 through siro spinning to obtain a high-shrinkage 40S / 1 40% HIGH SHRINKAGE POLYESTER60% POLY yarn;

[0062] (22) Set the 40S / 1 40% HIGH SHRINKAGE POLYESTER 60% POLY warp and weft knitting circular knitting machine, adjust the thread length to 28cm / 50G, adjust the conveying degree to 127°, the width of the cloth rack to 96cm, and the cloth rolling degree to 45°, The food position of the loom is separate food, the speed of the loom is 18 rpm, and the cloth embryo is woven by a rib knitting circular machine;

[0063] (23) In order to prev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com