Beam-splitting compound spinning method and special equipment thereof

A composite spinning and special device technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of unsatisfactory friction resistance, excessive hairiness, and easy pilling of yarns. To achieve the effect of reducing fiber tip exposure, reducing yarn hairiness, and improving strength and friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

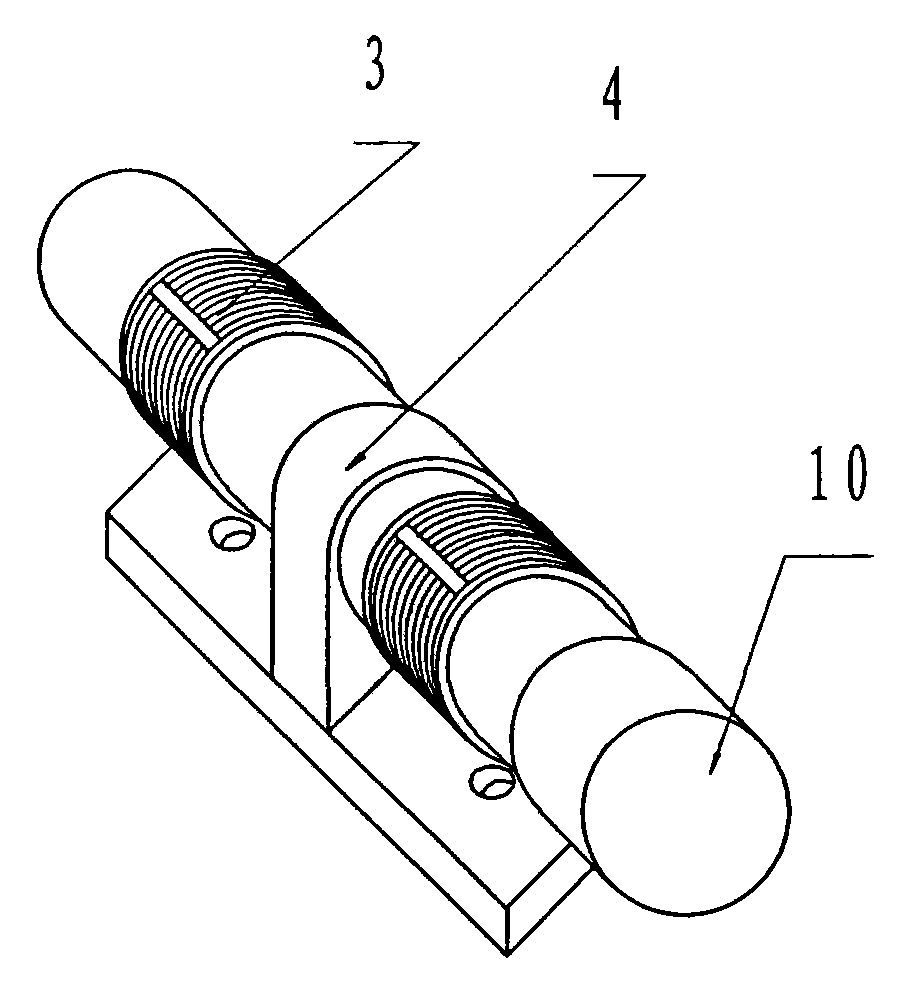

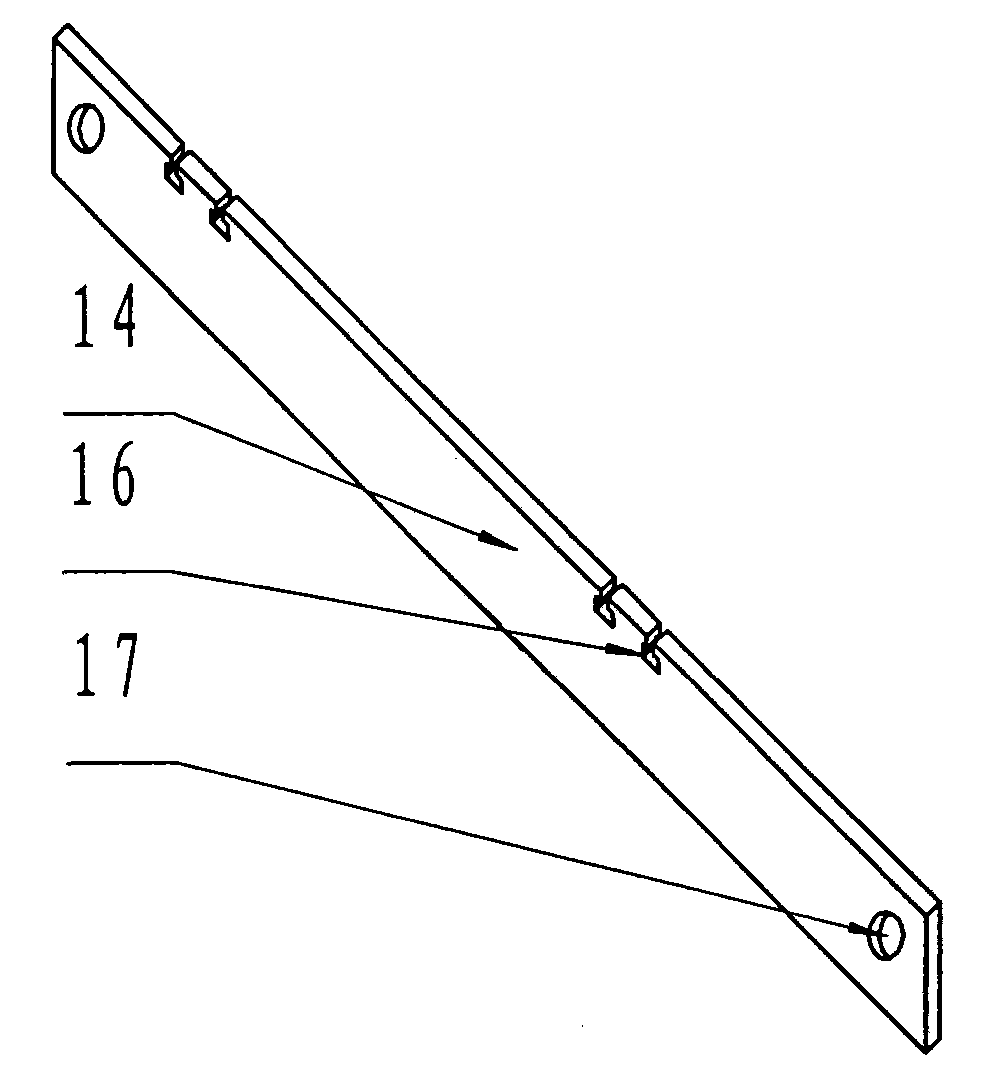

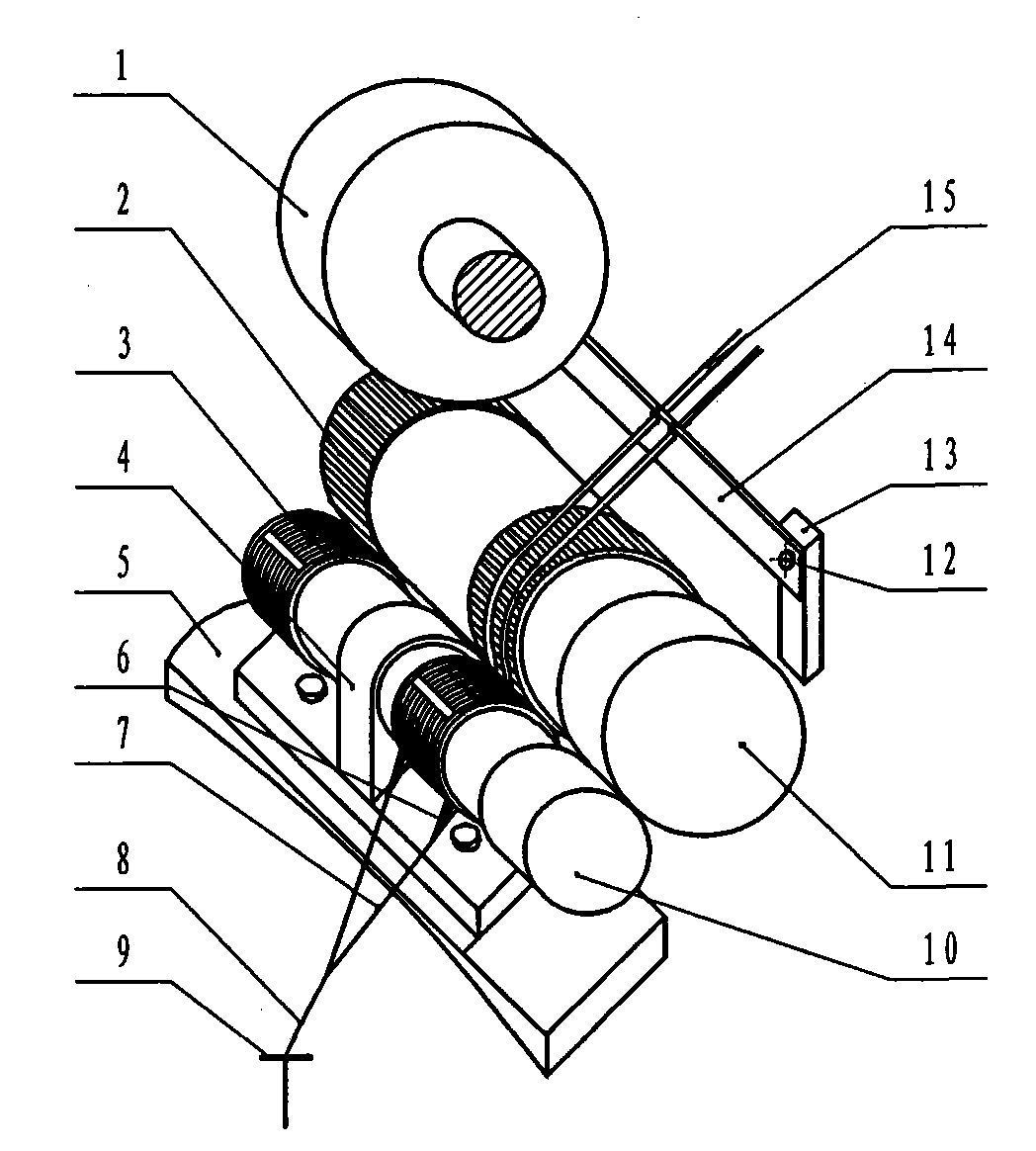

[0020] see figure 1 For the schematic diagram of the split wheel assembly, figure 2 It is a schematic diagram of the structure of the roving whisker separation plate, image 3 It is the application example diagram of the present invention on the spinning frame and Figure 4 As shown in the schematic diagram of the split wheel structure, the whisker separating plate 14 is fixed on the rear roller seat 13 of the spinning frame by screws 12, which can ensure the distance between two adjacent feeding roving whiskers 15 and keep them parallel to each other. The split wheel assembly is fixed on the panel 5 of the spinning frame by the fixing frame 4 . The transmission friction wheel 10 fixed on the split wheel shaft reliably contacts with the front roller friction wheel 11 of the spinning frame, and the axis of the entire split wheel shaft and the axis of the front roller 2 of the spinning frame are kept parallel.

[0021] During spinning, the two roving strands 15 enter the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com