Polysulphonamide fiber cable type spinning method

A technology of polysulfone fiber and cable type, which is applied in the field of spinning, can solve the problems of small cohesion between fibers, long hairiness, low yarn strength, etc., and achieve small elongation at break, small number of hairiness, and single yarn strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

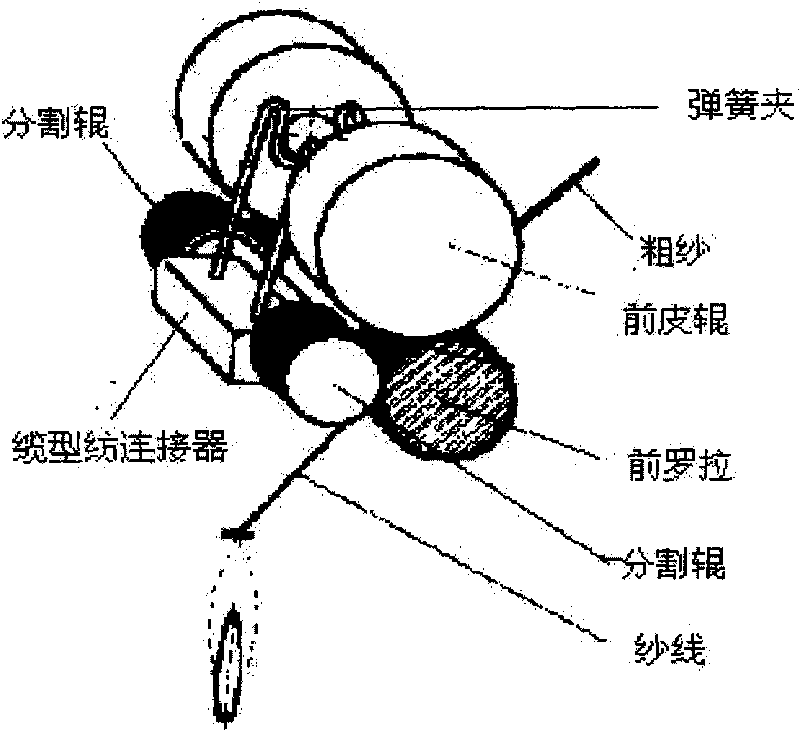

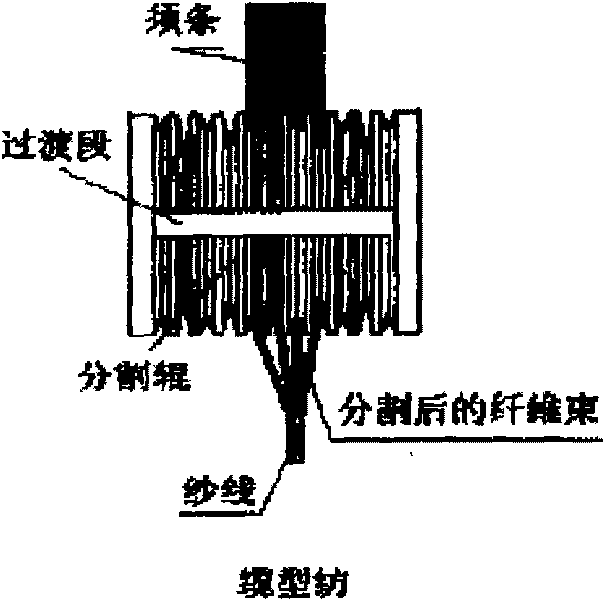

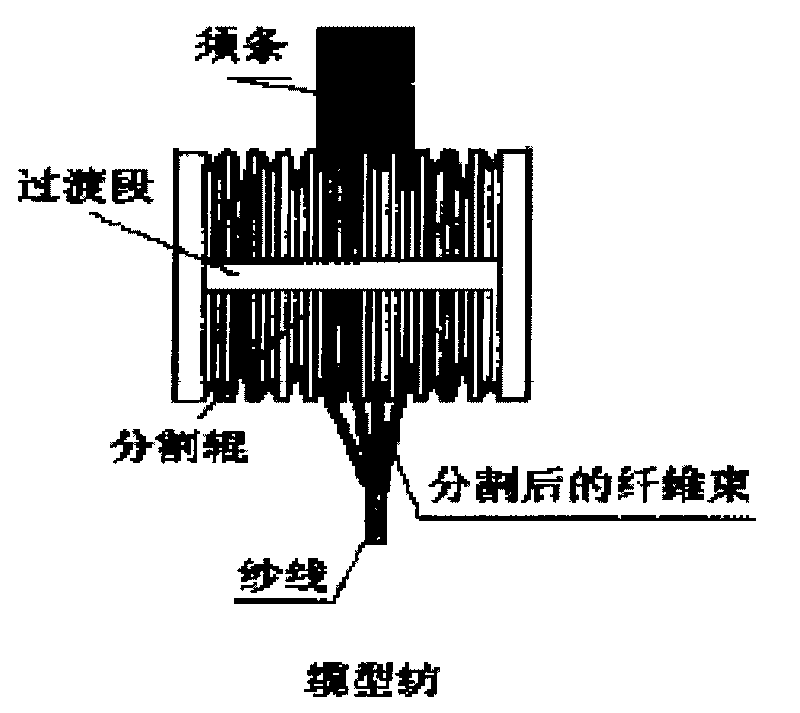

Method used

Image

Examples

Embodiment 1

[0023] Single yarn strength test and analysis:

[0024] Spun sulfonamide single yarn on FB505 spinning frame, 10 spindles adopt traditional spinning without cable spinning device; 10 spindles add cable spinning device, first spin 19.8 inch, twist 500 twist / m For spun yarn, adjust the spinning twist of the spinning machine after spinning a few winding yarns; other process parameters remain unchanged, spinning 19.8 inches of spun yarn with a twist of 450 twists / m, after spinning, from the spun Randomly select 10 bobbins of various spun yarns from the spun yarn, a total of 40 to test the single yarn strength and elongation at break. Each bobbin is tested 5 times, the test distance is 250mm, the tensile speed is 300 m / min, and the test single The results of yarn strength and elongation at break are shown in Table 1 and Table 2.

[0025] Table 1 Comparison of yarn strength between cable spinning and traditional spinning

[0026]

[0027] Table 2 Comparison of yarn elongation b...

Embodiment 2

[0035] Comparison of yarn hairiness between cable spinning and traditional spinning:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com