Colored polyesters and viscose blended siro-and-compact spinning yarns and manufacturing process

A siro compact, colored polyester technology, used in textiles, papermaking, yarn, etc., can solve problems such as easy slippage, difficult control, static electricity, etc., and achieve the effect of high yarn strength, compact structure and fewer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

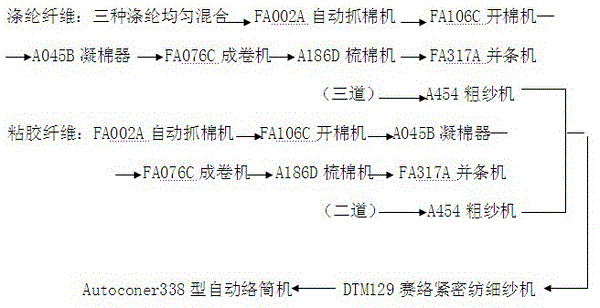

Method used

Image

Examples

Embodiment Construction

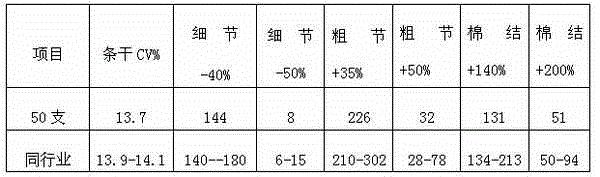

[0023] The present invention uses three kinds of colored polyesters and viscose to produce rovings of the same quantity respectively, and produces two-color yarns with three-dimensional effect on the Siro compact spinning frame; Polyester, at the same time, in order to improve the wearing performance, make it comfortable to wear, have good hygroscopicity and breathability, and do not generate static electricity, use 50% viscose; in order to improve the style of the cloth surface, it is free from pilling, less neps and color particles, and high strength , using siro compact spinning can achieve this effect.

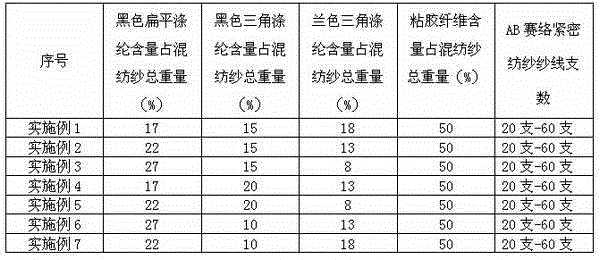

[0024] The further implementation scheme of the blended yarn of the present invention is: a kind of colored polyester and viscose blended siro compact spinning yarn, wherein, the content of black flat polyester accounts for 17%-27% of the total weight of the blended yarn, and the content of black triangular polyester accounts for 17%-27% of the total weight of the blended y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com