Bacteriostatic wicking anti-ultraviolet bamdal blended yarn and method for manufacturing same

A technology of anti-ultraviolet and bamboo generation, applied in the field of yarn, can solve the problems of fabric hand feeling, poor air permeability, poor fiber spinnability, poor anti-ultraviolet effect, etc. Effect of improving wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

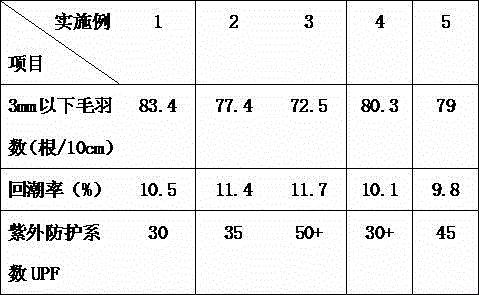

Examples

Embodiment 1

[0030] Raw material preparation: Bamboo dale fiber 0.8dtex×38mm

[0031] Moisture-wicking and UV-resistant super-spun cotton fiber 0.9dtex×38mm

[0032] The cross-section of the moisture-wicking and anti-ultraviolet super-spun cotton fiber is cross-shaped, and 0.8% nano-scale titanium dioxide powder is added to the spinning polymer mass during the spinning process.

[0033] Yarn Spec: Bamboo Dyer / Wicking & UV Resistant Superspun Cotton 30 / 70

[0034] 13.8tex, twist coefficient 280

[0035] The production process is as follows:

[0036] (1) Cleaning process:

[0037] Adoption process: FA002A type plucking machine → SFA035C type mixed cotton opener → FA025 type multi-compartment cotton blender → FA106A type porcupine opener → SFA161 type vibrating cotton feeder → A076F type lapping machine.

[0038] The bamboo dale fiber of the present invention, moisture-absorbing perspiration and anti-ultraviolet super-spun cotton fibers have good regularity, few impurities, smo...

Embodiment 2

[0051] Raw material preparation: bamboo dale fiber 0.9dtex×38mm

[0052] Moisture-wicking and UV-resistant super-spun cotton 0.9dtex×38mm

[0053] The cross-section of the moisture-wicking and anti-ultraviolet super-spun cotton fiber is cross-shaped, and 1.2% nano-scale titanium dioxide powder is added to the spinning polymer mass during the spinning process.

[0054] Yarn Spec: Bamboo Dyer / Wicking & UV Resistant Superspun Cotton 40 / 60

[0055] 13.8tex, twist factor 320

[0056] Spinning process:

[0057] (1) Cleaning process: After mixing the fibers according to the proportion, follow the principle of short process, low speed, less beating and less shedding, and the basis weight of the cotton lap is 380g / m;

[0058] (2) Carding process: cylinder speed is 310r / min, licker-in speed is 750r / min, doffer speed is 24r / min, cylinder doffer gauge is 0.12mm, raw sliver weight is 18.5g / 5m;

[0059] (3) Drawing process: adopt two merging, 8 slivers are merging,...

Embodiment 3

[0065] Raw material preparation: bamboo dale fiber 1.2dtex×38mm

[0066] Moisture-wicking and UV-resistant super-spun cotton 1.2dtex×38mm

[0067] The cross-section of the moisture-wicking and anti-ultraviolet super-spun cotton fiber is cross-shaped, and 2.2% of the mass of the spinning polymer is added with nano-scale titanium dioxide powder during the spinning process.

[0068] Yarn Spec: Bamboo Dyer / Wicking Anti-UV Superspun Cotton 50 / 50

[0069] 27.8tex, twist factor 360

[0070] The spinning process is the same as in Example 1.

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com