Bamboo charcoal fiber yarn and production method thereof

A technology of bamboo charcoal fiber and yarn is applied to the blended yarn and yarn of bamboo charcoal fiber and silk virgin fiber. performance, excellent moisture absorption and breathability, comfortable wearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

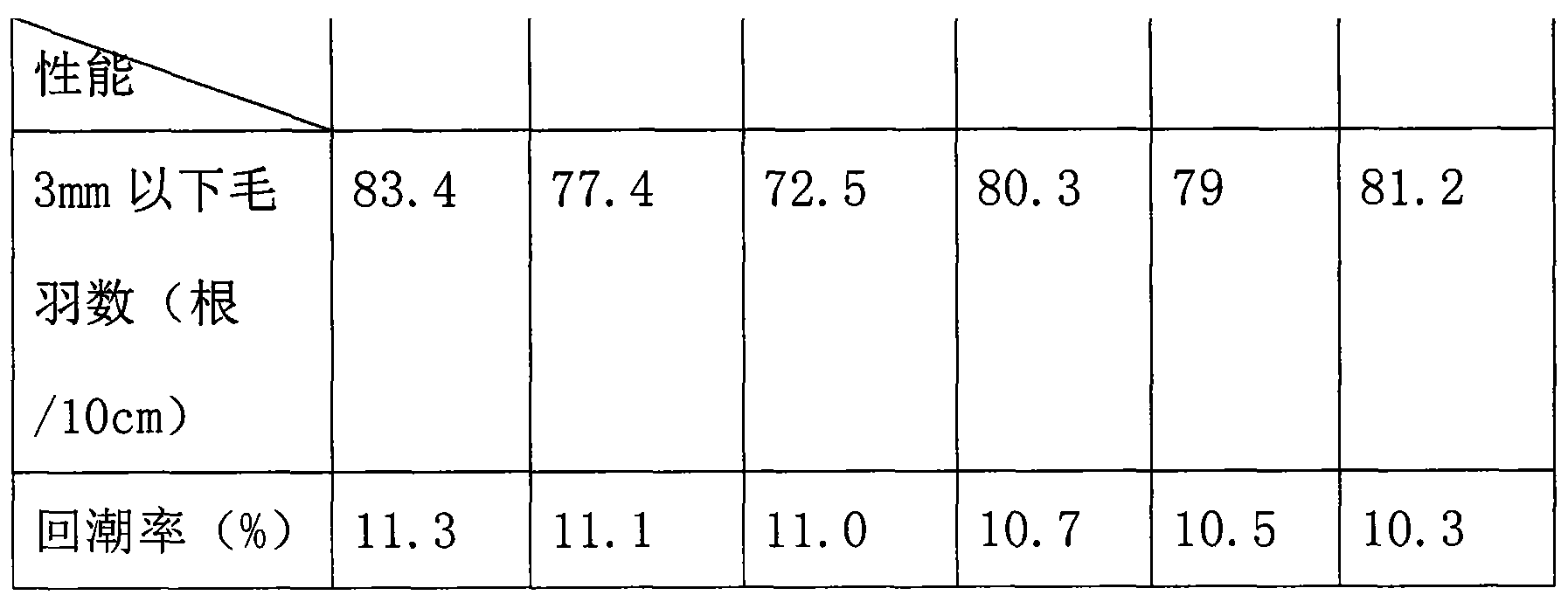

Embodiment 1

[0026] Raw material preparation: bamboo charcoal fiber 0.8dtex×38mm

[0027] Siweier fiber 0.9dtex×38mm

[0028] Yarn specification: bamboo charcoal fiber / silver 65 / 35

[0029] 13.8tex, twist coefficient 380

[0030] The production process is as follows:

[0031] (1) Cleaning process:

[0032] Adoption process: FA002A type plucking machine → SFA035C type mixed cotton opener → FA025 type multi-compartment cotton blender → FA106A type porcupine cotton opener → SFA161 type vibrating cotton feeder → A076F type lapping machine.

[0033] The bamboo charcoal fiber and silk fiber fiber of the present invention have good regularity, few impurities, smooth fiber surface, poor cohesion force between fibers, and good opening performance. In addition, the fibers have poor resilience and are easily damaged by mechanical force. The FA002A cotton bale machine should grasp frequently, take less and hit less, and reduce the rotation speed of each beater appropriately. ...

Embodiment 2

[0045] Raw material preparation: bamboo charcoal fiber 0.8dtex×38mm

[0046] Siweier fiber 0.9dtex×38mm

[0047]Yarn specification: bamboo charcoal fiber / silver 65 / 35

[0048] 13.8tex, twist factor 420

[0049] The spinning process is the same as in Example 1.

Embodiment 3

[0051] Raw material preparation: bamboo charcoal fiber 0.8dtex×38mm

[0052] Siweier fiber 0.9dtex×38mm

[0053] Yarn specification: bamboo charcoal fiber / silver 65 / 35

[0054] 13.8tex, twist coefficient 460

[0055] The spinning process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com