Fibre bundle opening device for an open-end spinning device and feeding trough for the fibre bundle opening device

A technology of fiber sliver and loose mechanism, which is applied in the field of feeding plate, can solve the problem of no fiber bundle support geometry description, etc., and achieve the effect of improved yarn value, high yarn strength, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

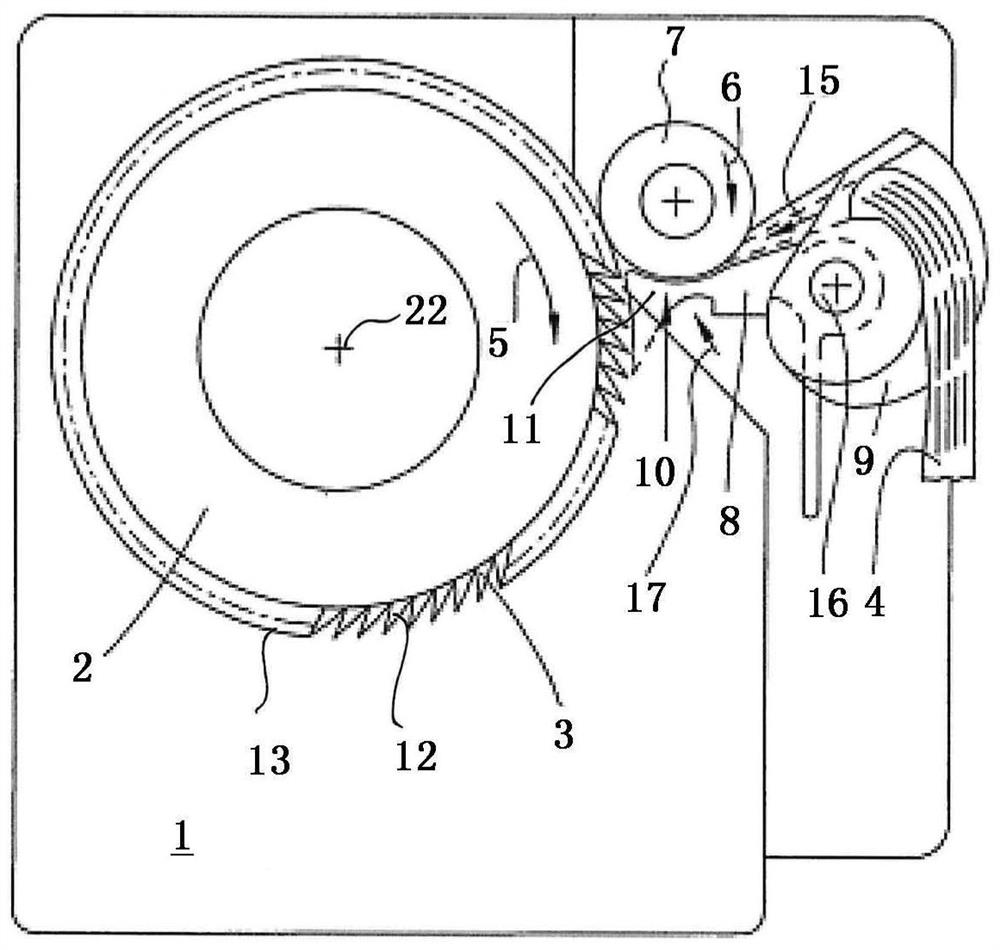

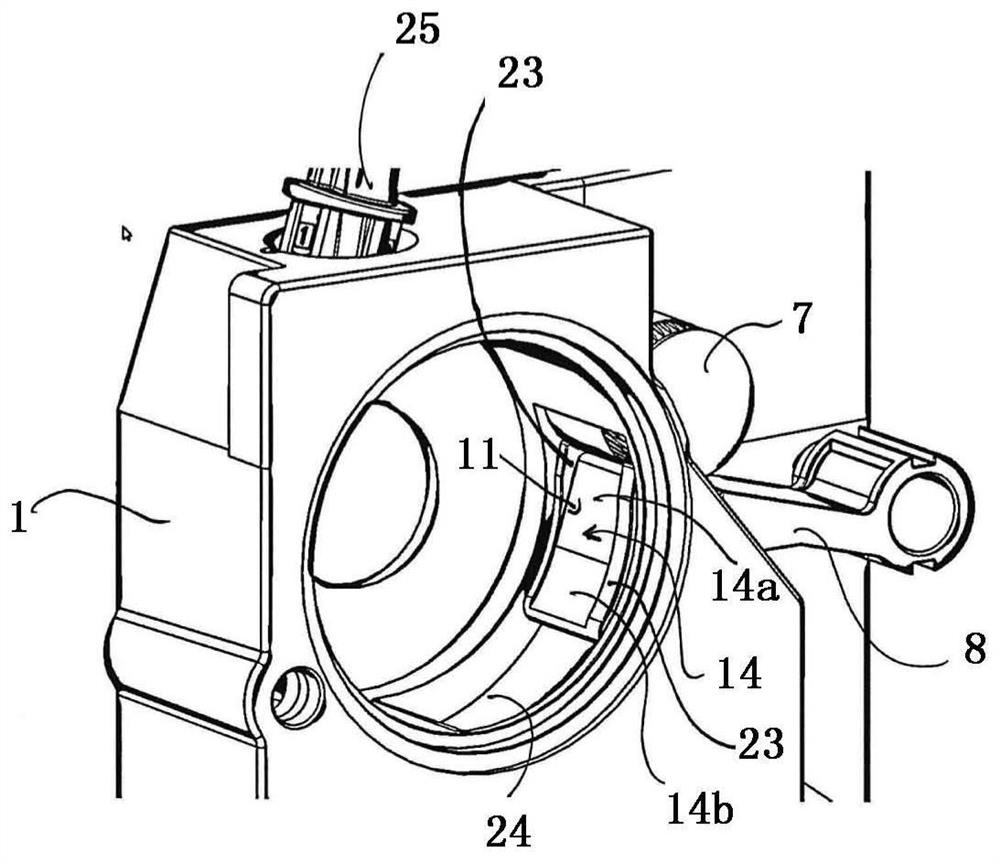

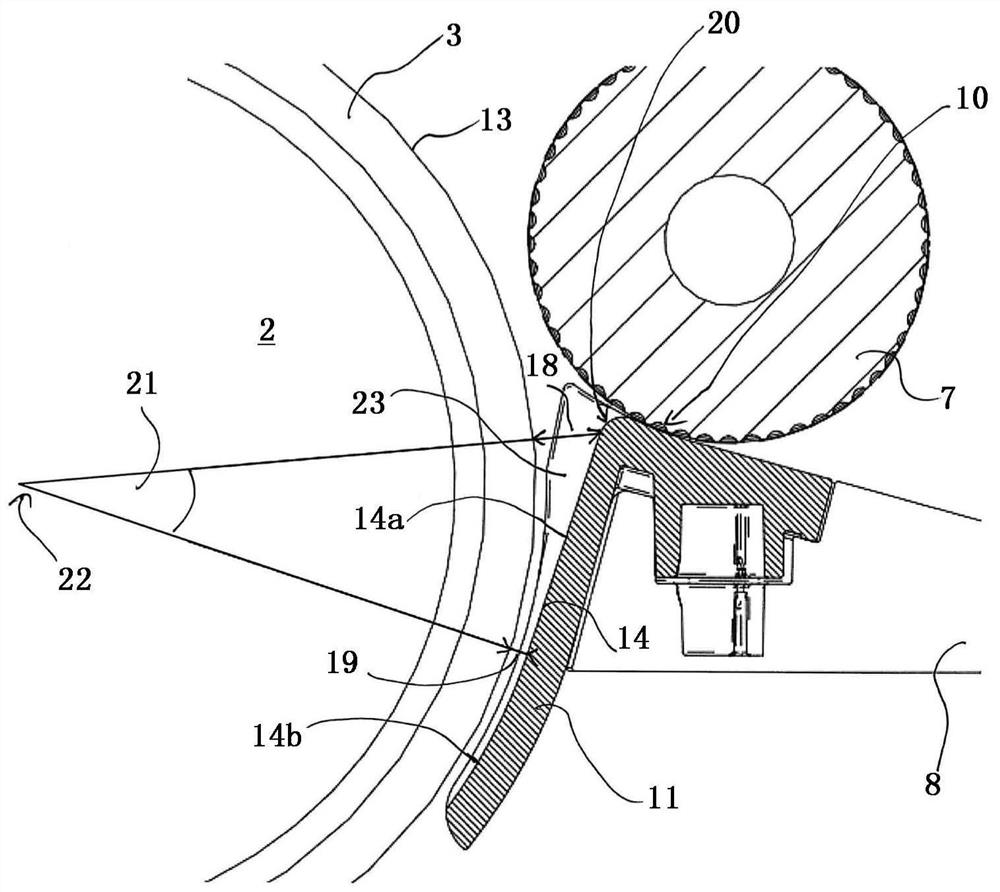

[0048] figure 1 An opening roller housing 1 for a sliver opening mechanism of an open-end spinning device is shown. An opening roller 2 is mounted rotatably around a rotation axis 22 in the opening roller housing 1 . The opening roller 2 has a so-called opening roller clothing 3 on its outer circumference for carding the feed fiber sliver 4 . The opening roller clothing 3 comprises teeth, the tips of which lie on a cylindrical surface 13 which delimits the opening roller 2 . The opening roller 2 rotates in the direction of arrow 5 during the spinning operation.

[0049] In or at the opening roller housing 1, a fiber strip feeding drum 7 rotatable in the direction of arrow 6 is also installed. It corresponds to the clamping face 10 of the feed plate 11 which is pivotably mounted by means of the feed plate seat 8 . Such as figure 1As shown, the feed fiber sliver 4 that is usually stored in a spinning can, not shown, is sent by the agglomeration device 9 in the direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com