Composite twisted yarn

a technology of twisted yarn and composite yarn, which is applied in the field of composite twisted yarn, can solve the problems of difficult production of core spun yarn (1), difficult to produce core spun yarn of fine count, and practically inadequate core spun yarn (1) for small lot production, and achieves low production cost, low fluff, and good usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

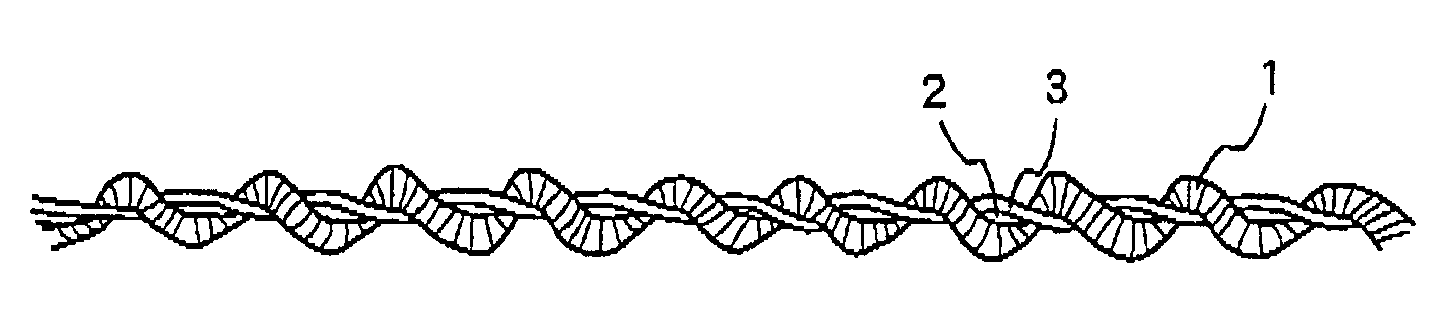

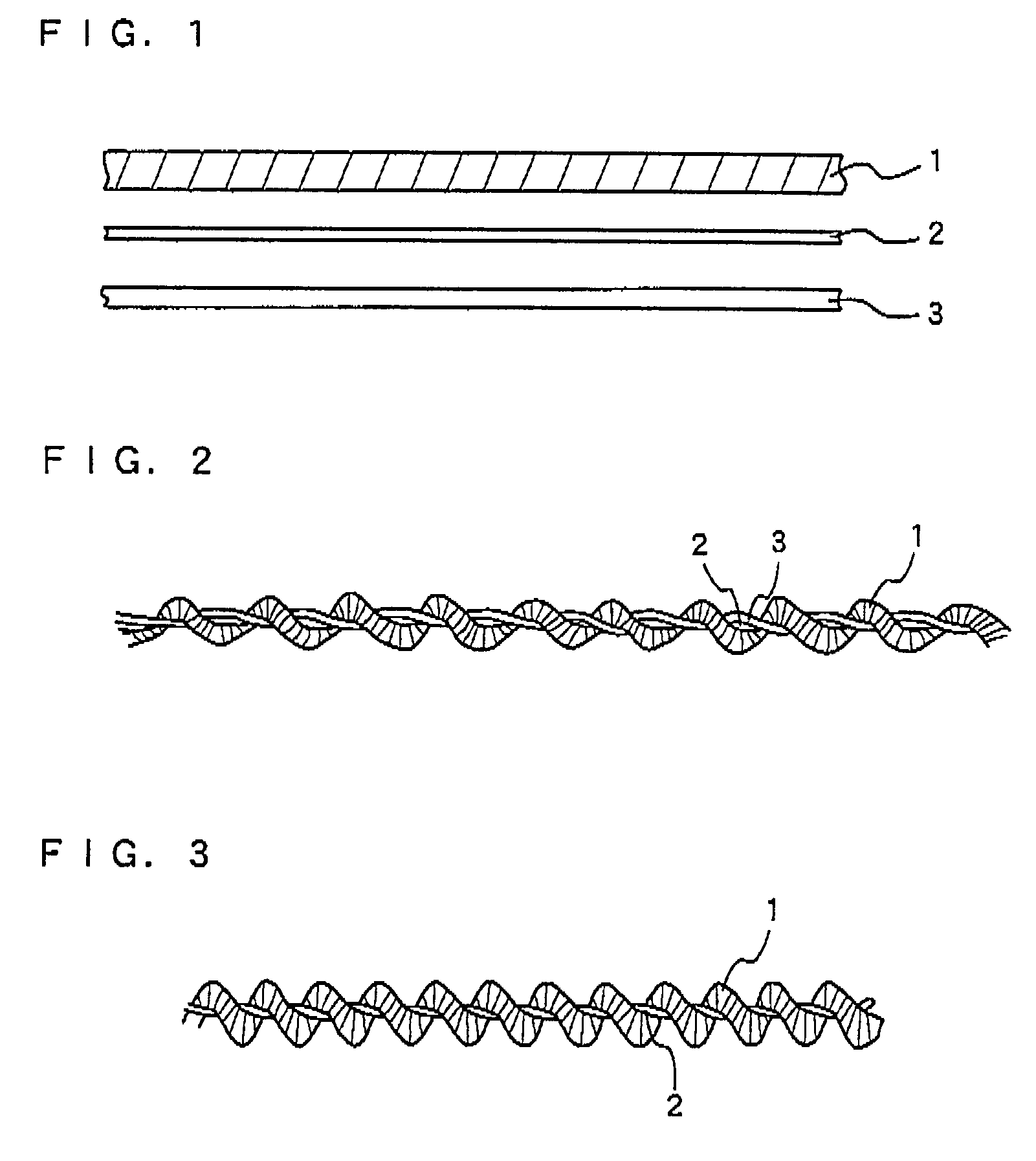

[0106](1) (i) A spun yarn (twist number: 600 times / m (Z twist), cotton 100%, yarn count No. 20, manufactured by Tsuzuki Bouseki K. K., “TS 20 single yarn”) was prepared. Incidentally, the spun yarn had a twist number “T” of 15.24 times per 2.54 cm (inch) and a yarn count number “S” of 20, thus the twist factor “K” found by the formula: K=(T / √S) was 15.24 / √20=15.24 / 4.47=3.24.

[0107](ii) As the water-soluble yarn, a polyvinyl alcohol multifilament yarn (56 dtex) (a yarn dissolving in water at 80° C.) (manufactured by Kuraray Co., Ltd., “Water-soluble vinylon”) was prepared.

[0108](2) One piece of the spun yarn prepared in the above step (1) and one piece of the water-soluble yarn were supplied to a double twister (manufactured by Murata Machinery, Ltd., “36M”), and these yarns were twisted at (so as to have) a twist number (second twist) of 1000 times / m (S twist) to give a composite twisted yarn [the ratio of the twist number “B” of the composite twisted yarn relative to the twist numbe...

example 2

[0112](1) A plain weave fabric having 25 warp yarns / cm and 20 weft yarns / cm was woven (mixing rate of the composite twist yarn in the plain weave fabric=40% by weight) by using a cotton two ply yarn (count No. 40) as the warp yarn and the composite twisted yarn obtained in the step (2) of Example 1 as the weft yarn. In the weaving step, the warp yarn was woven without sizing treatment. Nevertheless, the plain weave fabric could be produced by weaving without any problems such as thread breakage at high speed (weaving speed: 0.1 m / minute) and with excellent weaving productivity.

[0113](2) The plain weave fabric obtained in step (1) was soaked in hot water at 80° C. for 30 minutes (bath ratio=1:10), the water-soluble yarn in the composite twisted yarn constituting the weft yarn of the fabric was dissolved and removed, then the fabric was taken out of the water (bath) and was dried at 150° C. for 2 minutes. In the thus obtained fabric, the elongations of the fabric in the warp direction...

example 3

[0114](1) (i) A spun yarn (twist number: 800 times / m (Z twist), cotton 100%, yarn count No. 40, manufactured by Tsuzuki Bouseki K. K., “TS 40 single yarn”) was prepared, then two pieces of the spun yarn were supplied to a double twister (manufactured by Murata Machinery, Ltd., “36M”) and twisted at a twist number (second twist) of 600 times / m (S twist) to give a two ply yarn.

[0115](ii) As the water-soluble yarn, a polyvinyl alcohol multifilament yarn (56 dtex) (a yarn dissolving in water at 80° C.) (manufactured by Kuraray Co., Ltd., “Water-soluble vinylon”) was prepared.

[0116](2) One piece of the two ply yarn (spun yarn) prepared in the above step (1) and one piece of the water-soluble yarn were supplied to a double twister (manufactured by Murata Machinery, Ltd., “36M”), and these yarns were twisted at a twist number (second twist) of 1000 times / m (Z twist) to give a composite twisted yarn [the ratio of the twist number “B” of the composite twisted yarn relative to the twist numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com