Tancel bamboo charcoal denim-simulated fabric

A technology imitating denim and tencel bamboo, which is applied in the field of textile fabrics, can solve the problems of smooth appearance, fine and delicate hand feeling of wearing comfort, poor air permeability and comfortable drape, and easy wrinkle of cotton fabrics, etc., to achieve Increase the appearance of drape, comfort, and increase the effect of hand feeling and drape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

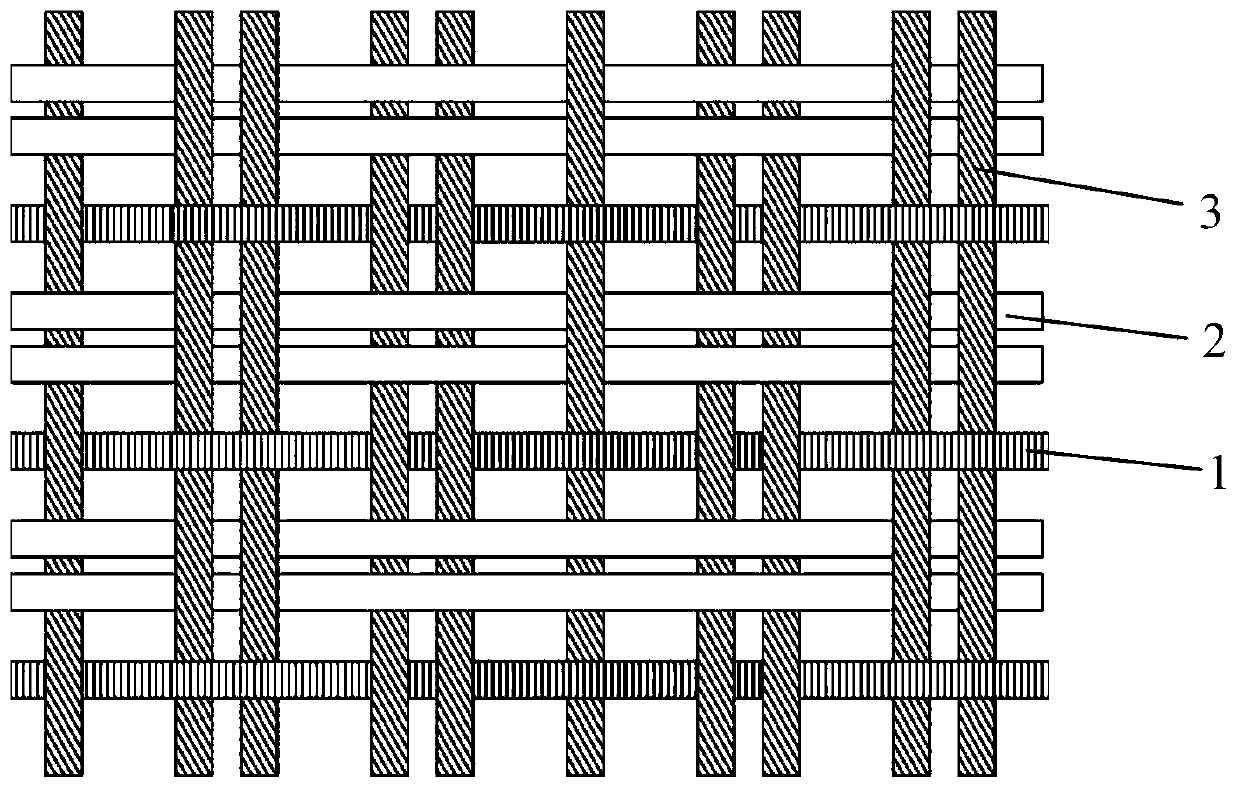

[0019] A kind of tencel bamboo charcoal imitation denim fabric with 12×21 jacquard structure, which is woven with tencel, bamboo charcoal fiber, spandex, polyester and cotton, interwoven by warp yarn and weft yarn. The direction yarn is composed of 21.8 parts of Tencel and 36.4 parts of cotton, the weft direction yarn is composed of 12 parts of bamboo charcoal fiber, 27.2 parts of polyester and 2.6 parts of spandex, and the warp direction yarn is made of Tencel and cotton blended The slub yarn, the specification of the slub yarn is 20SB.

[0020] The slub yarn is woven from cotton and tencel by a compact spinning weaving method.

[0021] The bamboo charcoal fiber is 32S double-strand yarn, the polyester is 250D polyester filament, and the specification of the spandex is 70D.

[0022] The bamboo charcoal fiber, polyester and spandex are juxtaposed up and down, and arranged continuously in this order.

[0023] The warp density of the denim-like fabric made of Tencel bamboo cha...

Embodiment 2

[0027] A kind of tencel bamboo charcoal imitation denim fabric with 12×21 jacquard structure, which is woven with tencel, bamboo charcoal fiber, spandex, polyester and cotton, interwoven by warp yarn and weft yarn. The direction yarn is composed of 25 parts of Tencel and 35 parts of cotton, the weft direction yarn is composed of 11.3 parts of bamboo charcoal fiber, 26.7 parts of polyester and 2 parts of spandex, and the warp direction yarn is made of a blend of Tencel and cotton The slub yarn, the specification of the slub yarn is 20SB.

[0028] The slub yarn is woven from cotton and tencel by a compact spinning weaving method.

[0029] The bamboo charcoal fiber is 30S double-strand yarn, the polyester is 200D polyester filament, and the specification of the spandex is 70D.

[0030] The bamboo charcoal fiber, polyester and spandex are juxtaposed up and down, and arranged continuously in this order.

[0031] The warp density of the denim-like fabric made of Tencel bamboo char...

Embodiment 3

[0035] A kind of tencel bamboo charcoal imitation denim fabric with 12×21 jacquard structure, which is woven with tencel, bamboo charcoal fiber, spandex, polyester and cotton, interwoven by warp yarn and weft yarn. The direction yarn is composed of 25 parts of Tencel and 35 parts of cotton, the weft direction yarn is composed of 12 parts of bamboo charcoal fiber, 25 parts of polyester and 2 parts of spandex, and the warp direction yarn is a blend of Tencel and cotton The slub yarn, the specification of the slub yarn is 21SB.

[0036] The slub yarn is woven from cotton and tencel by a compact spinning weaving method.

[0037] The bamboo charcoal fiber is 40S double-strand yarn, the polyester is 250D polyester filament, and the specification of the spandex is 70D.

[0038] The bamboo charcoal fiber, polyester and spandex are juxtaposed up and down, and arranged continuously in this order.

[0039] The warp density of the denim fabric imitating Tencel bamboo charcoal is 105, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com