Glycolipid separation and purification method

A technology for separating and purifying glycolipids, which is applied in the field of deep processing of soybean oil leftovers, can solve the problems of low separation efficiency, difficult to meet the requirements of further research on glycolipid structure identification and biological activity, and time-consuming, and achieves the yield of glycolipids. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

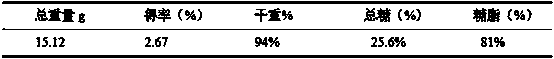

[0030] Embodiment 1: Separation and purification of glycolipids from crude phospholipids

[0031] Use a measuring cylinder to take 500ml (567g) of crude phospholipids (soybean oil leftovers) into a 2000ml large beaker, add 750ml of n-hexane, and keep stirring until the crude phospholipids are completely dissolved, then transfer them to a 2000ml separating funnel. Prepare 750ml of 50% (w / w) ethanol aqueous solution, pour 250ml of ethanol aqueous solution into the n-hexane phospholipid system for the first time, shake up and down for 5 minutes, then let stand to separate layers, take the upper ethanol aqueous solution; pour 250ml of ethanol for the second time Put the aqueous solution into the n-hexane phospholipid system, shake it up and down for 5 minutes, then let it stand for stratification, and take the upper layer of ethanol water solution; for the third time, pour 250ml of ethanol water solution into the n-hexane phospholipid system, shake it up and down for 5 minutes, th...

Embodiment 2

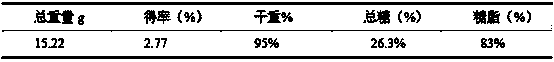

[0042] Embodiment 2: Separation and purification of glycolipids from crude phospholipids

[0043] Use a measuring cylinder to take 500ml (550g) of crude phospholipids into a 2000ml large beaker, add 750ml of n-hexane, and keep stirring until the crude phospholipids are completely dissolved, then transfer to a 2000ml separatory funnel. Prepare 750ml of 60% (w / w) ethanol aqueous solution, pour 250ml of ethanol aqueous solution into the n-hexane phospholipid system for the first time, shake up and down for 5min, then let stand to separate layers, take the upper layer of ethanol aqueous solution; pour 250ml of ethanol for the second time Put the aqueous solution into the n-hexane phospholipid system, shake it up and down for 5 minutes, then let it stand for stratification, and take the upper layer of ethanol water solution; for the third time, pour 250ml of ethanol water solution into the n-hexane phospholipid system, shake it up and down for 5 minutes, then let it stand for stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com