Bonding pad-based electroplating lead design

A technology of electroplating lead wires and pads, which is applied to printed circuit components, electrical connection printed components, and electrical connection formation of printed components. , to achieve the effect of reducing the impact and avoiding appearance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

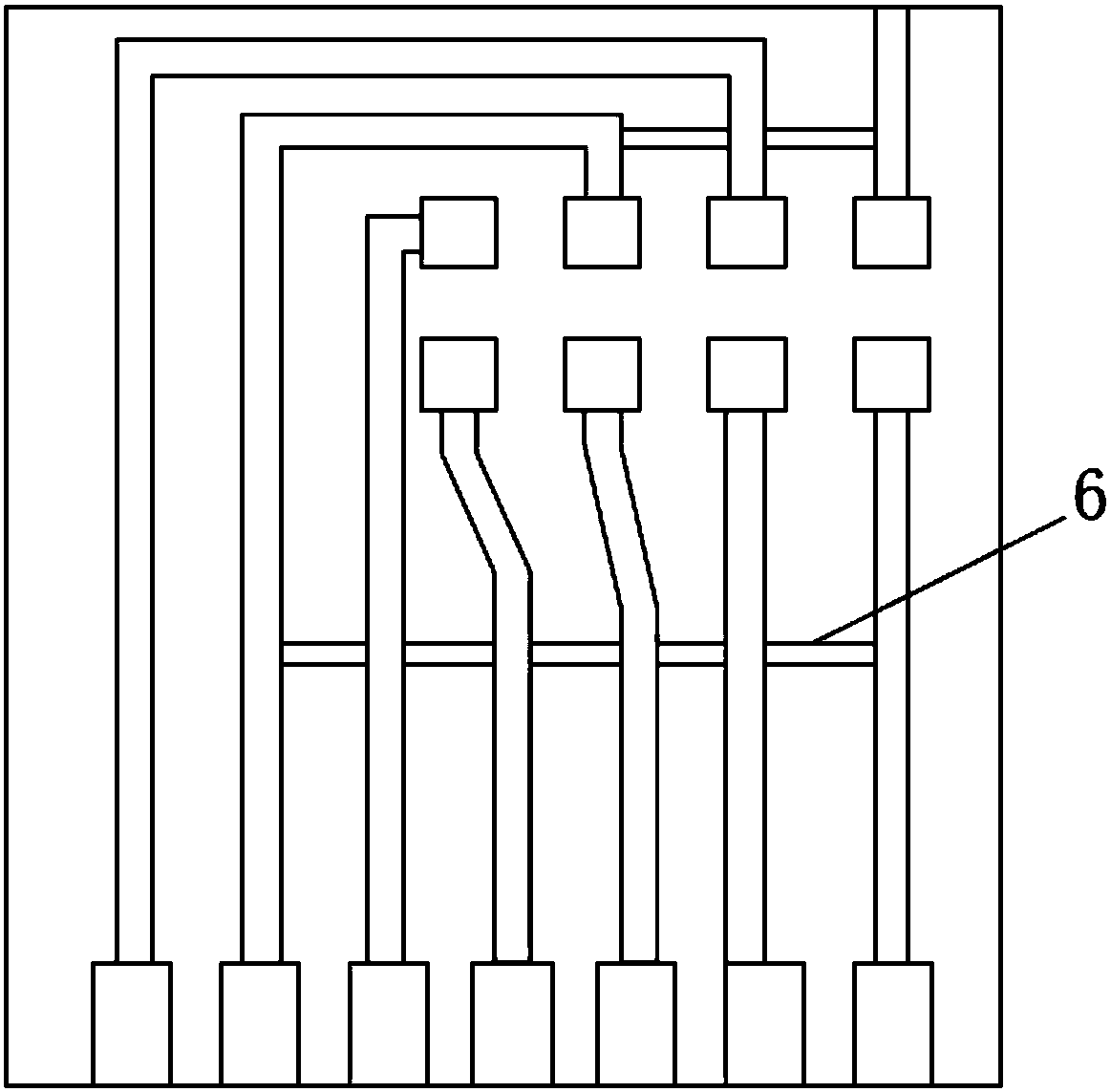

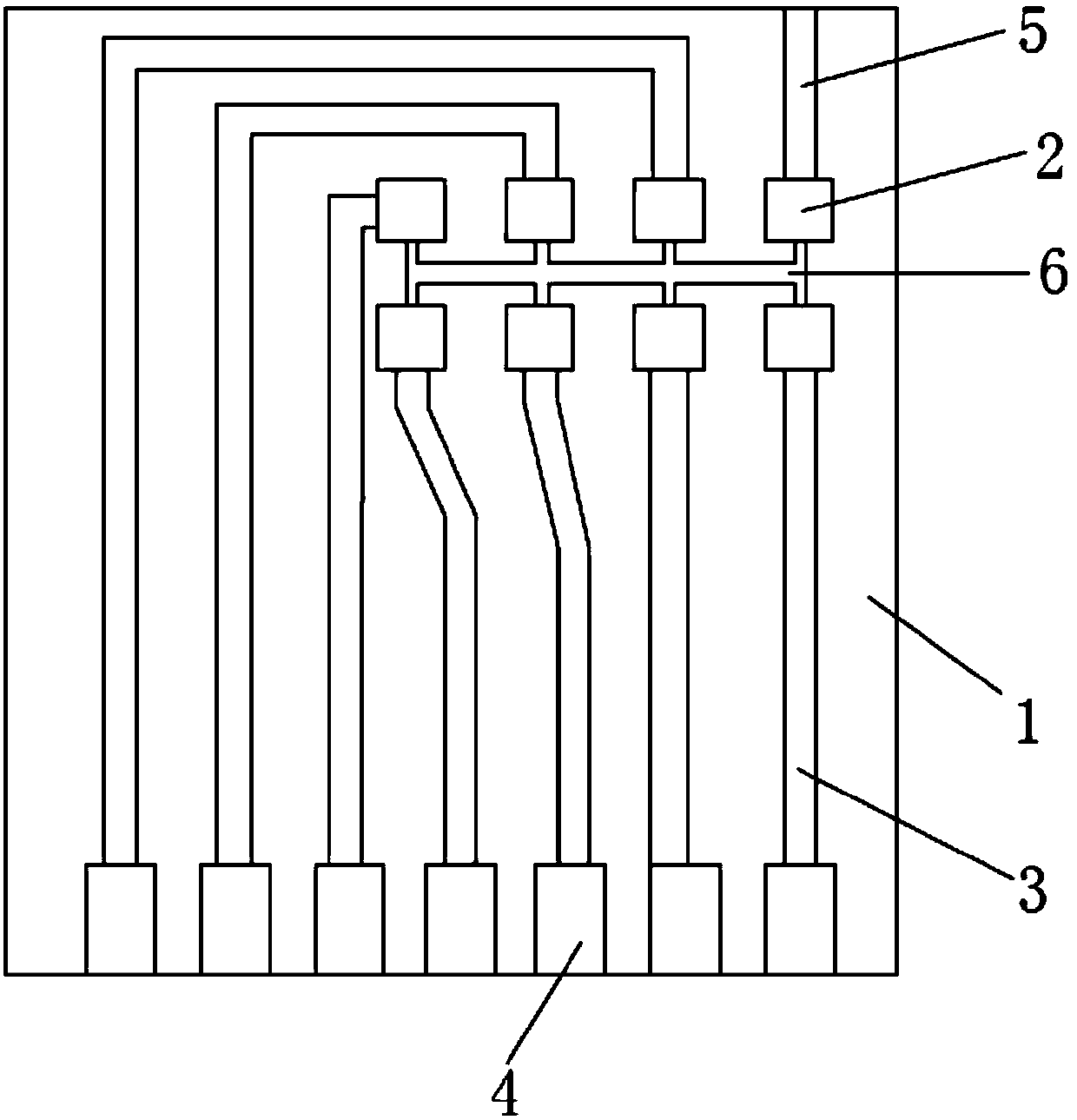

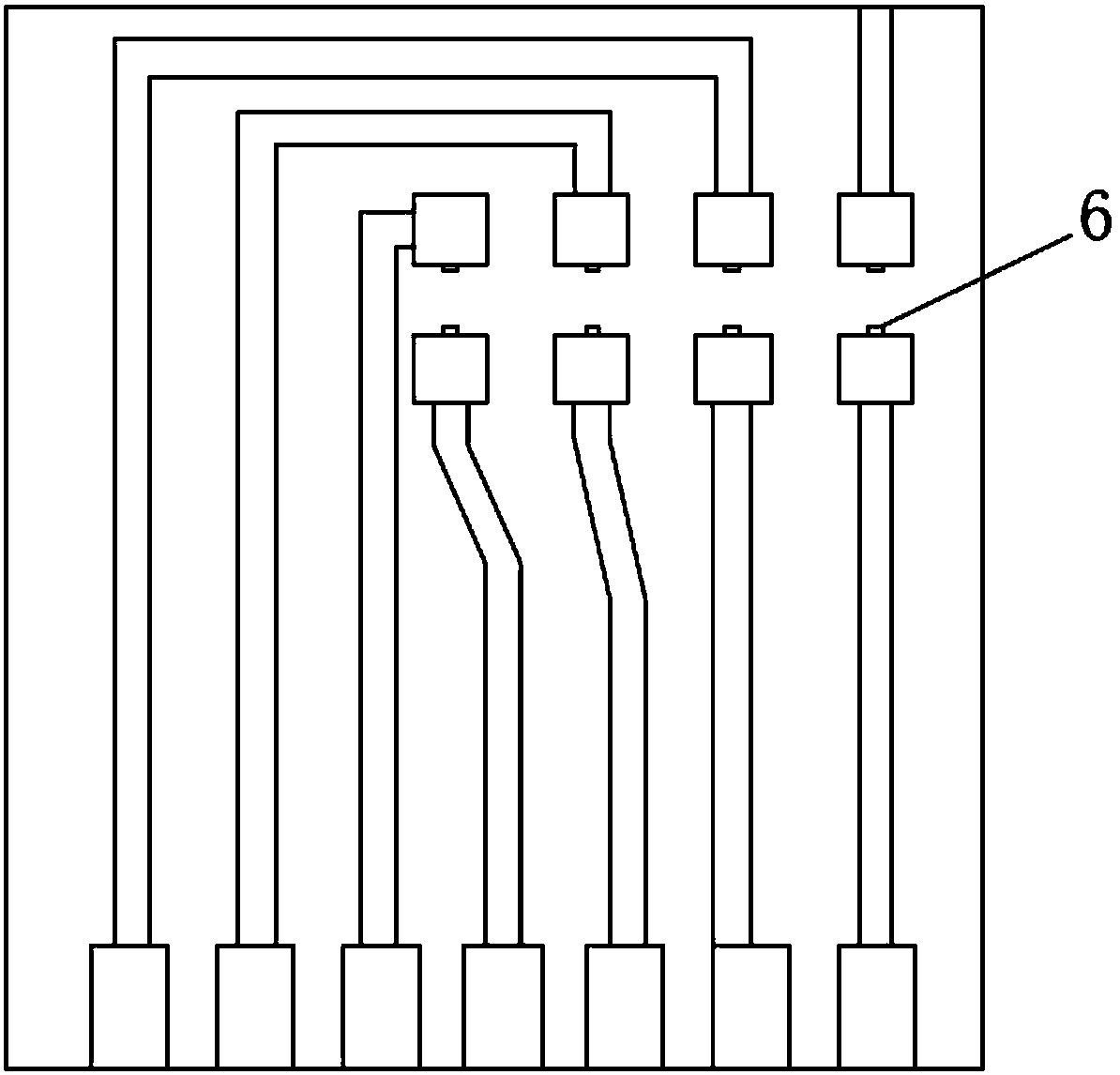

[0019] Such as figure 2 As shown, a kind of pad-based electroplating lead design shown in this embodiment includes 8 pads 2 arranged on the circuit board 1, wherein 7 pads 2 are connected to the circuit board provided on the circuit board through the signal line 3 respectively. The gold fingers 4 are connected, and the remaining 1 pad 2 is connected to the edge of the circuit board 1 through the wire 5. The 8 pads 2 are arranged in 2 rows and 4 columns, and the electroplating lead 6 is set in the middle of the 2 rows of pads 2, and the electroplating The leads 6 are connected to the eight pads 2 on both sides, so that the eight pads 2 communicate with each other through the electroplating leads 6 , and the electroplating leads 6 communicate with the electroplating current through the wires 5 connected to the edge of the board through the pads 2 .

[0020] Wherein the signal line 3 and the wire 5 and the electroplating lead 6 are separately arranged on two opposite sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com