Polyamide material with excellent appearance, low water absorption and self-tapping slipping resistance, preparation method and application thereof

A low water absorption and polyamide technology, applied in the field of polymer materials, can solve the problems of not meeting the application requirements of electric kettle thermostats, not comprehensively considering the appearance of finished products, self-tapping slippery wire, and material fluidity decline, etc., to achieve reduction The risk of high torque self-tapping slippery wire, the improvement of serious appearance problems of floating fibers, and the effect of low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

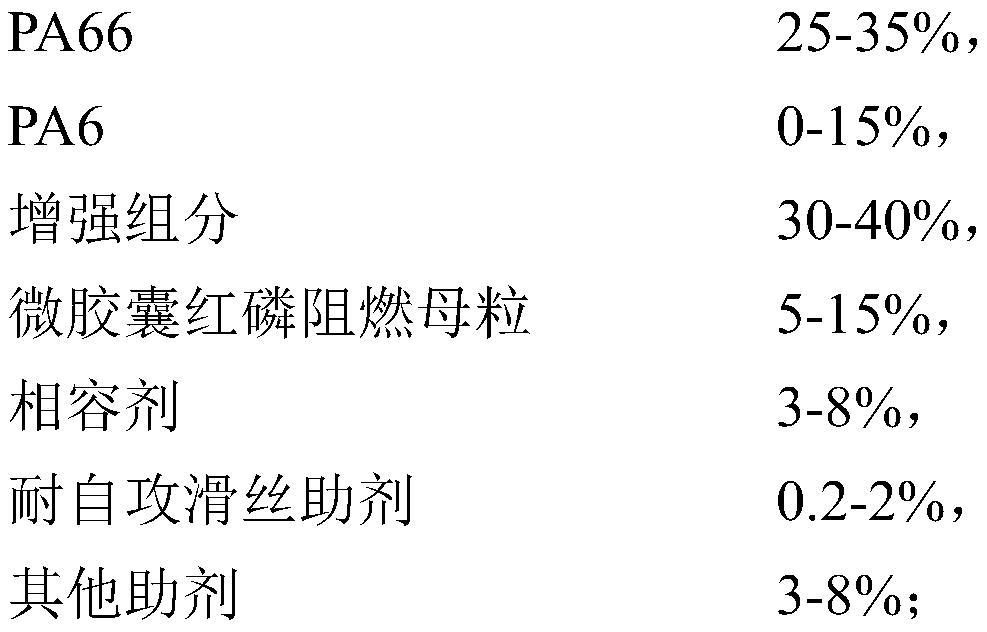

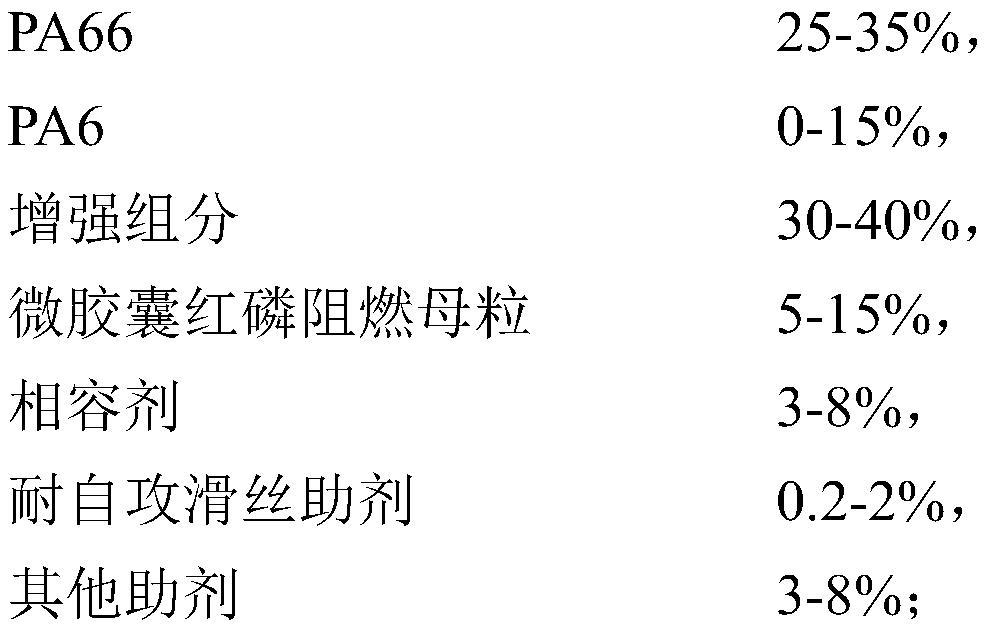

Method used

Image

Examples

Embodiment Construction

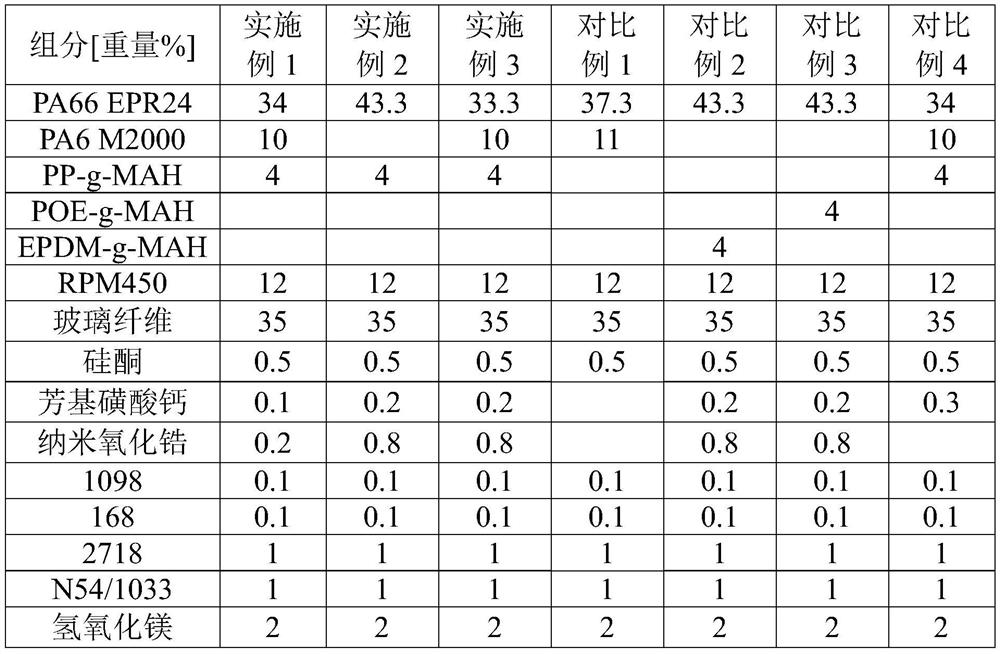

[0031] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. The operating methods not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

[0032] The raw materials used in the following examples and comparative examples are as follows:

[0033] PA66: EPR24 China Shenma Group Co., Ltd.

[0034] PA6: M2000 Guangdong Xinhui Meida Nylon Co., Ltd.

[0035] Microencapsulated red phosphorus flame retardant masterbatch: RPM450 provided by China Blue Chenguang Chemical Research Institute Co., Ltd.

[0036] Glass fiber: ECS11--4.5--568H, Jushi Group Co., Ltd.

[0037] Compatibilizer:

[0038] Maleic anhydride grafted EPDM rubber (EPDM-g-MAH), commercially available

[0039] Malei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com