Back shell of display and film for protecting back shell

A display, film technology, applied in the direction of film/sheet release liner, film/sheet adhesive, adhesive type, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

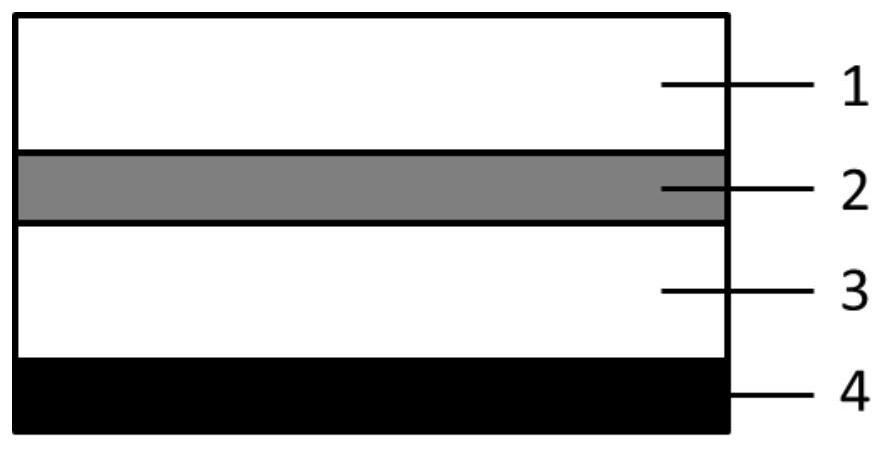

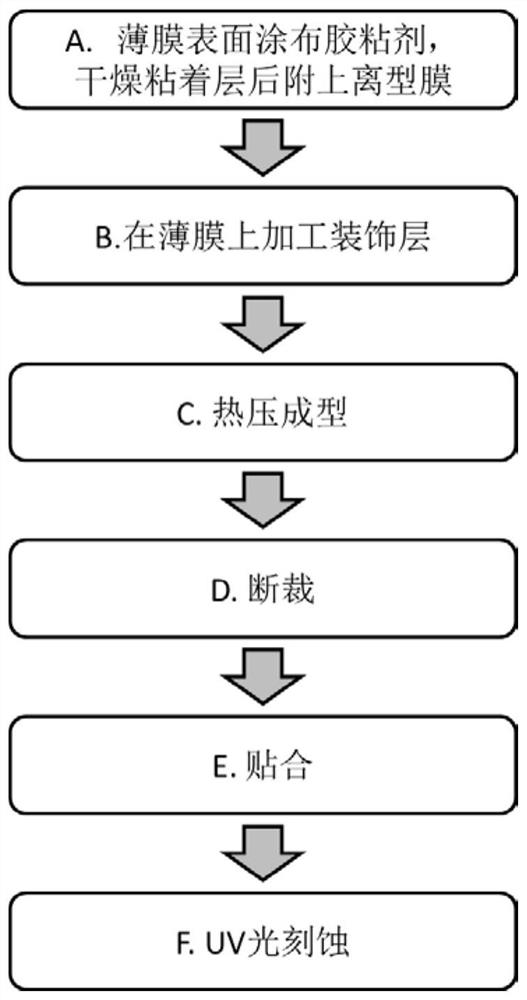

[0060] After coating adhesive a on one side of film A, dry at 120°C for 2 minutes, attach release film I, and print ink I on the other side, dry and cure at 75°C for 60 minutes. Thin film A is thermoformed at 120℃*15s to make a curved decorative explosion-proof film with R6mm arc chamfer on the long side. After cutting, tear off the release film I and stick it on the inside of the cover plate 1. After the bonding is completed, use 355nm UV light to perform pattern etching from the shell side. Observe the appearance of the laminated product after completion.

Embodiment 2

[0062] After coating adhesive a on one side of the film B, dry it at 120°C for 2 minutes, attach the release film I, and print ink I on the other side, dry and solidify at 75°C for 60 minutes. Thin film B is thermoformed at 120°C for 15s to make a curved decorative explosion-proof film with R6mm arc-shaped chamfer on the long side. After cutting, tear off the release film I and stick it on the inside of the cover plate 1. After the bonding is completed, use 355nm UV light to perform pattern etching from the shell side. Observe the appearance of the laminated product after completion.

Embodiment 3

[0064]After coating adhesive a on one side of film C, dry it at 120°C for 2 minutes, attach release film I, and print ink I on the other side, dry and solidify at 75°C for 60 minutes. Thin film C is thermoformed at 120°C for 15s to make a curved decorative explosion-proof film with R6mm arc-shaped chamfer on the long side. After cutting, tear off the release film I and stick it on the inside of the cover plate 1. After the bonding is completed, use 355nm UV light to perform pattern etching from the shell side. Observe the appearance of the laminated product after completion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com