Stainless steel sheet, preparation method and electronic equipment

A technology of stainless steel plate and stainless steel, which is applied in metal material coating process, decorative art, superimposed layer plating, etc., and can solve problems that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

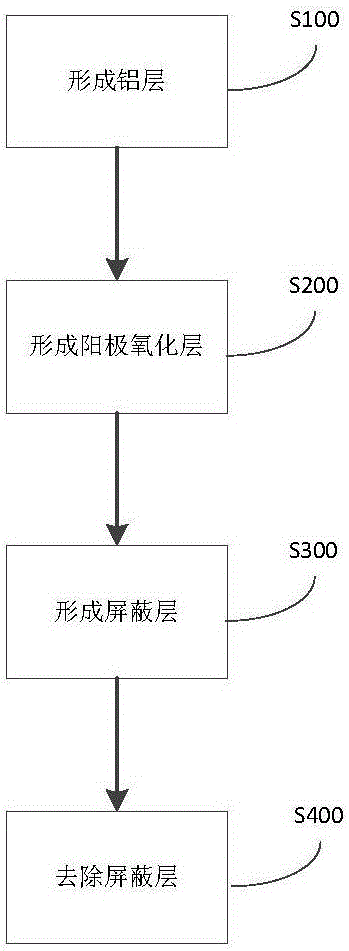

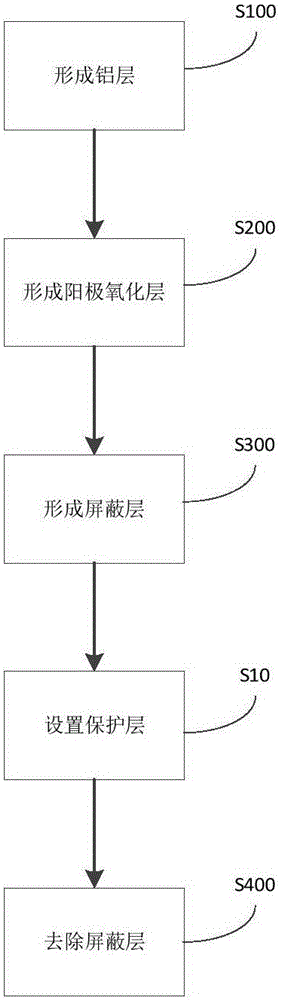

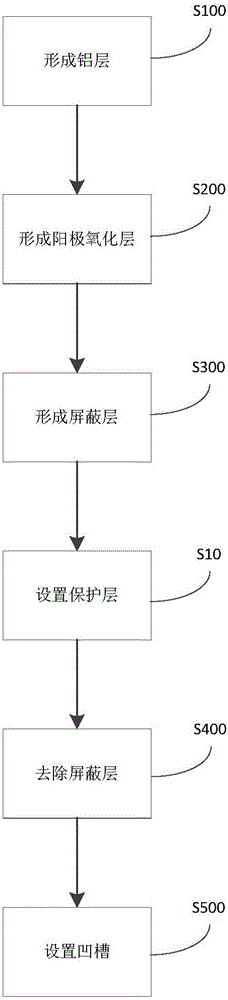

Embodiment 1

[0077] A stainless steel plate with a thickness of 0.4mm is used to stamp and form a stainless steel substrate of 0.4mm; an aluminum layer with a thickness of 50-60um is formed on the stainless steel substrate by vacuum sputtering, and the conditions of vacuum sputtering are: temperature 400 Above ℃, the average high-speed electron current is 20v, and the time is 20-30min. Perform anodic oxidation treatment on the aluminum layer to form an anodic oxidation layer with a thickness of 8-12 μm, and the conditions of anodic oxidation treatment are conventional oxidation parameters. At this time, the thickness of the remaining aluminum layer between the anodized layer and the stainless steel substrate is more than 30 μm to ensure adhesion. A shielding layer is formed on the upper surface of the anodized layer by spraying masking or high temperature protective film. Use ABB mechanical grinding or manual polishing to remove the anodized layer and aluminum layer other than the shieldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com