Automobile tail lamp functional module and LED circuit board installation method thereof

A technology for LED circuit boards and automobile tail lights, which is applied to motor vehicles, road vehicles, signal devices, etc., can solve the problems of affecting the appearance, insufficient space to install LEDs, exposed circuit boards, etc., to achieve light weight, better overall effect and beautiful appearance , the effect of high light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

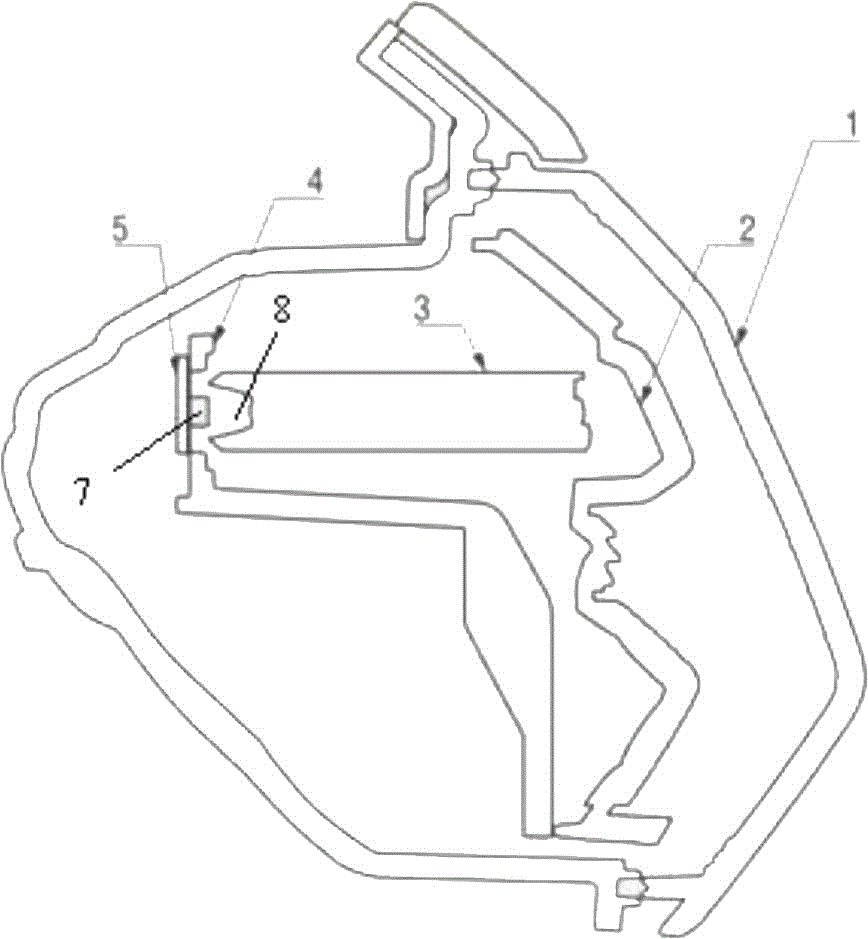

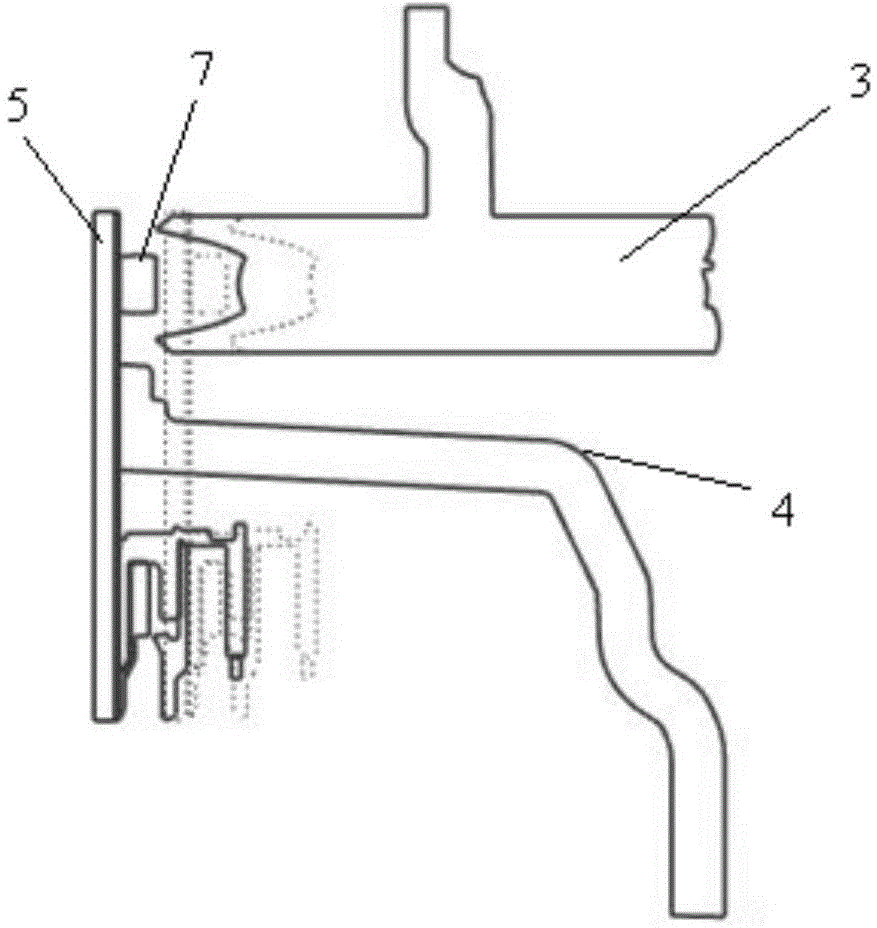

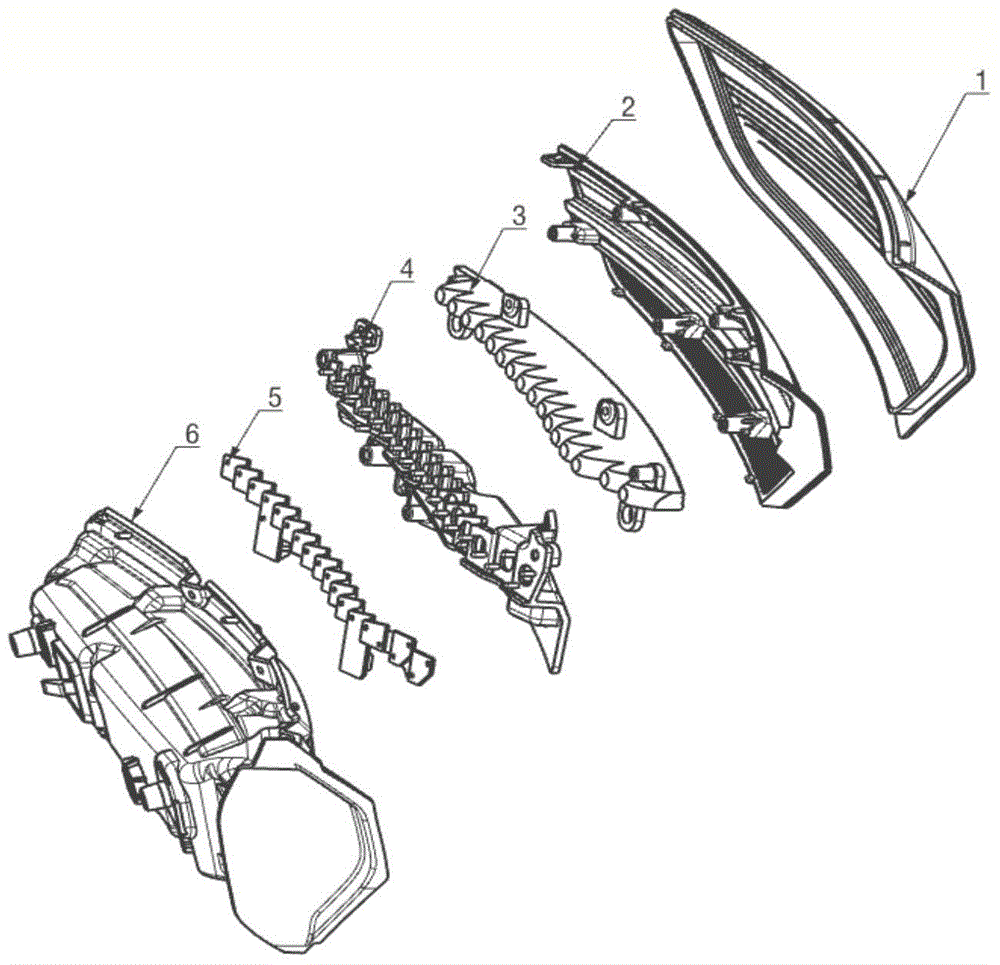

[0027] Such as figure 1 As shown, the functional module of the automobile tail light of the present invention includes several LED light sources 7, transparent light guide plates 3, LED mounting brackets 4 and LED circuit boards 5, and the transparent light guide plates 3 are fixed on the LED mounting brackets 4 Above, one end of the transparent light guide plate 3 has a sawtooth structure, and the other end is provided with a groove 8 , and each groove is provided with an LED light source 7 fixed on the LED circuit board 5 . The LED light source is arranged in each groove, so that the LED light source can be hidden in all directions, and at the same time, the light utilization rate is high, the luminous purity is high, and the color is bright.

[0028] The transparent light guide plate 3 is located on the front of the LED installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com