Solar double-glass photovoltaic module laminating and edge sealing adhesive tape and preparation method thereof

A double-glass photovoltaic and component layer technology, applied in coatings, adhesives, pressure-sensitive films/sheets, etc., to achieve good adhesion, uniform edge thickness, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

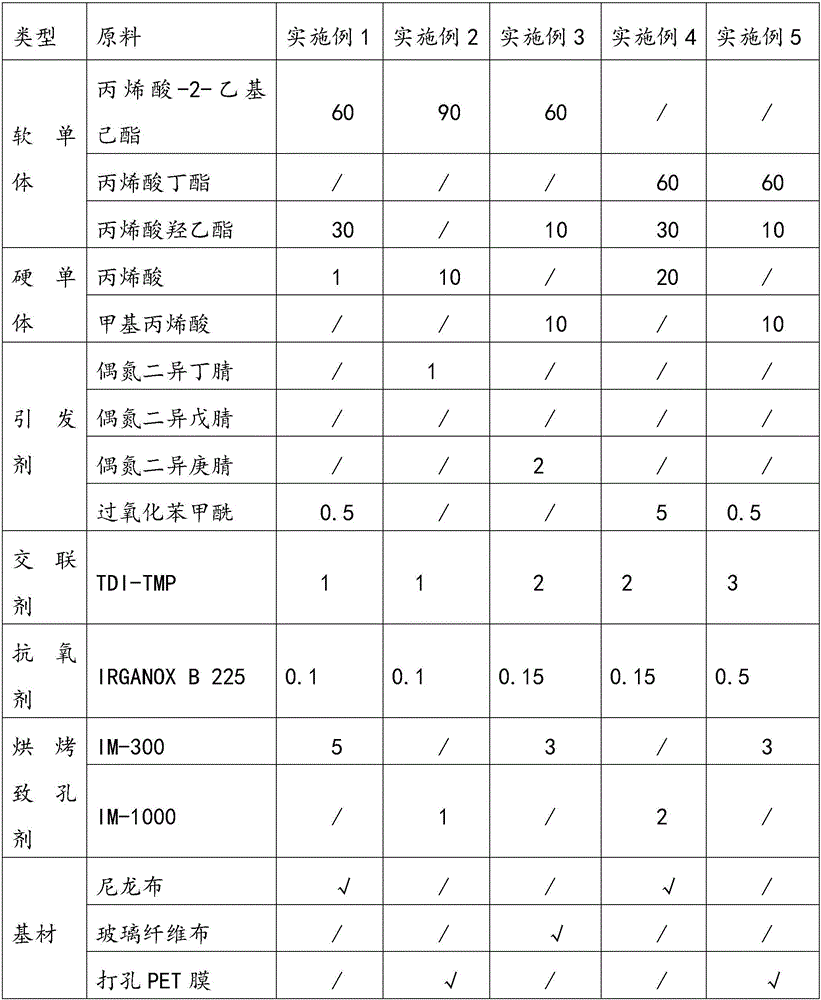

[0027] The used raw materials of embodiment 1-5 are as shown in table 1:

[0028] Table 1: The kind of raw material that embodiment 1-5 uses

[0029]

[0030] Table 2: Performance test data of the edge banding tape obtained in Examples 1-5

[0031] Glue viscosity / mPas 3450 4400 2350 3742 5820 Tape thickness / μm 30 30 30 30 30 Peel strength / N / mm 0.75 1.10 0.60 0.58 0.62 Holding power / h >72 >72 >72 >72 >72 Heat resistance / min, 150℃ >60 >60 >60 >60 >60 air permeability OK OK OK OK OK

[0032] The preparation method of the edge sealing tape of embodiment 1-5 is as follows:

[0033] First, 10wt% of the total amount of acrylate monomers and 10wt% of the total amount of hard monom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com